Search Results (Searched for: )

- lgrfbs

03 Nov 2024 18:12

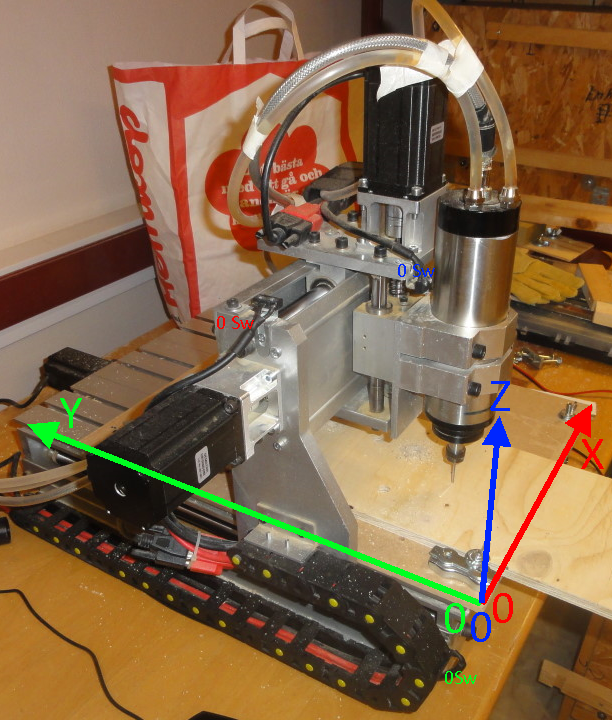

Z axis goes in the wrong direction, so after home-all was created by lgrfbs

Z axis goes in the wrong direction, so after home-all

Category: StepConf Wizard

- anfänger

03 Nov 2024 15:12

Replied by anfänger on topic Ignore hard and or softlimits for toolchange

Ignore hard and or softlimits for toolchange

Category: General LinuxCNC Questions

- Aciera

03 Nov 2024 14:02

Replied by Aciera on topic Ignore hard and or softlimits for toolchange

Ignore hard and or softlimits for toolchange

Category: General LinuxCNC Questions

- fletch

03 Nov 2024 14:00

Replied by fletch on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- Aciera

03 Nov 2024 13:43

Replied by Aciera on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- anfänger

03 Nov 2024 13:41

Replied by anfänger on topic Ignore hard and or softlimits for toolchange

Ignore hard and or softlimits for toolchange

Category: General LinuxCNC Questions

- fletch

03 Nov 2024 12:50

Replied by fletch on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- Aciera

03 Nov 2024 12:42 - 03 Nov 2024 12:43

Replied by Aciera on topic Ignore hard and or softlimits for toolchange

Ignore hard and or softlimits for toolchange

Category: General LinuxCNC Questions

- Aciera

03 Nov 2024 12:30

- JT

03 Nov 2024 12:26

- fletch

03 Nov 2024 12:26 - 03 Nov 2024 12:28

Replied by fletch on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- JT

03 Nov 2024 11:42

Replied by JT on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- Creative25

- Creative25

03 Nov 2024 11:34

Replied by Creative25 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 11:31

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- martin2day

- martin2day

03 Nov 2024 11:21

Replied by martin2day on topic Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Category: Milling Machines

Time to create page: 0.632 seconds