Search Results (Searched for: )

- tommylight

03 Nov 2024 01:51

Replied by tommylight on topic Ini File Clarification/Roadmap?

Ini File Clarification/Roadmap?

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 01:48

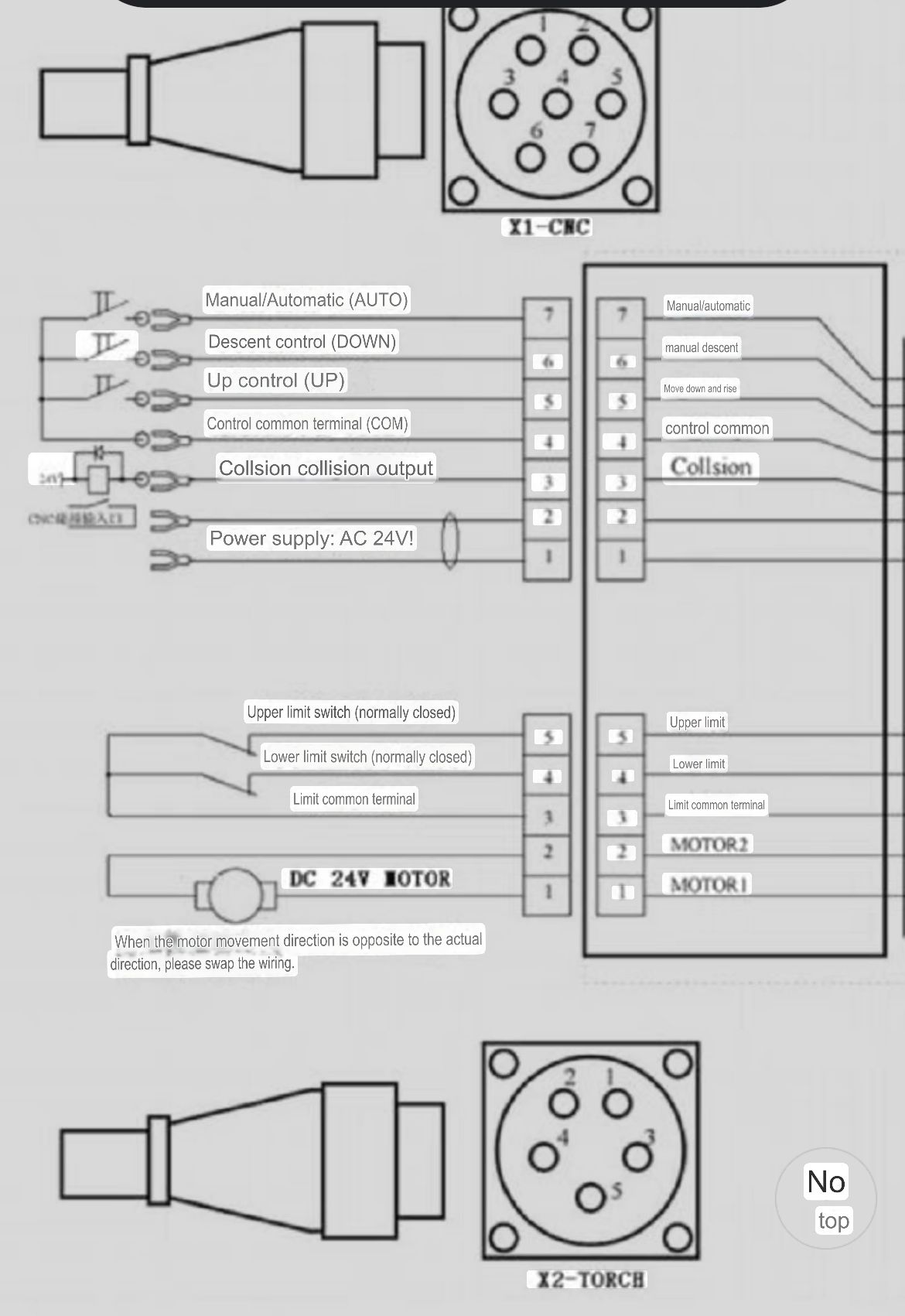

Replied by tommylight on topic Integrating a CHC-200F Capacitive sensor as a THC

Integrating a CHC-200F Capacitive sensor as a THC

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 01:43

Replied by tommylight on topic Carte d'adaptateur PCI Express vers parallèle DB25

Carte d'adaptateur PCI Express vers parallèle DB25

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 01:37

Replied by tommylight on topic Integrating a CHC-200F Capacitive sensor as a THC

Integrating a CHC-200F Capacitive sensor as a THC

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 00:59

Replied by tommylight on topic Best cam software to use for plasma cutting

Best cam software to use for plasma cutting

Category: CAD CAM

- tray

- tray

03 Nov 2024 00:34

- tray

- tray

03 Nov 2024 00:32

- EW_CNC

02 Nov 2024 23:31

Replied by EW_CNC on topic Best cam software to use for plasma cutting

Best cam software to use for plasma cutting

Category: CAD CAM

- Project_Hopeless

02 Nov 2024 23:24

Replied by Project_Hopeless on topic pyVCP Button to Float Output

pyVCP Button to Float Output

Category: HAL

- sin-do-re

- sin-do-re

02 Nov 2024 22:36 - 02 Nov 2024 22:39

Integrating a CHC-200F Capacitive sensor as a THC was created by sin-do-re

Integrating a CHC-200F Capacitive sensor as a THC

Category: General LinuxCNC Questions

- PCW

02 Nov 2024 21:51 - 02 Nov 2024 21:52

- akb1212

- akb1212

02 Nov 2024 20:43

Replied by akb1212 on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- slowpoke

- slowpoke

02 Nov 2024 20:26

- GDTH

02 Nov 2024 19:54

Replied by GDTH on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- tcbmetalworks

- tcbmetalworks

02 Nov 2024 19:27

Replied by tcbmetalworks on topic Best cam software to use for plasma cutting

Best cam software to use for plasma cutting

Category: CAD CAM

Time to create page: 0.587 seconds