Search Results (Searched for: )

- HogWild

- HogWild

21 Oct 2024 19:45

- btvpimill

- btvpimill

21 Oct 2024 19:44

Replied by btvpimill on topic Machine moves when you stop program in the middle

Machine moves when you stop program in the middle

Category: General LinuxCNC Questions

- NTULINUX

21 Oct 2024 18:47

Replied by NTULINUX on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- TheProcessTechnician

- TheProcessTechnician

21 Oct 2024 18:08

Replied by TheProcessTechnician on topic Homing switches dont react, CNC goes on.

Homing switches dont react, CNC goes on.

Category: Basic Configuration

- deltafox24

- deltafox24

21 Oct 2024 17:57 - 21 Oct 2024 18:04

Problem with Huanyang VFD communication via RS485 in LinuxCNC was created by deltafox24

Problem with Huanyang VFD communication via RS485 in LinuxCNC

Category: General LinuxCNC Questions

- kbec

- kbec

21 Oct 2024 17:52

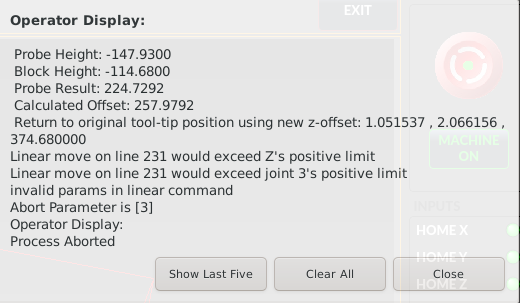

Help with probe/tool setter in qtdragon was created by kbec

Help with probe/tool setter in qtdragon

Category: Other User Interfaces

- martin2day

- martin2day

21 Oct 2024 17:46

- gardenweazel

21 Oct 2024 17:19

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- gardenweazel

21 Oct 2024 17:17

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- Grotius

21 Oct 2024 17:14

Replied by Grotius on topic c++ compiling error

c++ compiling error

Category: Advanced Configuration

- Grotius

21 Oct 2024 16:49

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- PCW

21 Oct 2024 16:47

Replied by PCW on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- vmihalca

- vmihalca

21 Oct 2024 16:23

Replied by vmihalca on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- Macwolf

- Macwolf

21 Oct 2024 16:15

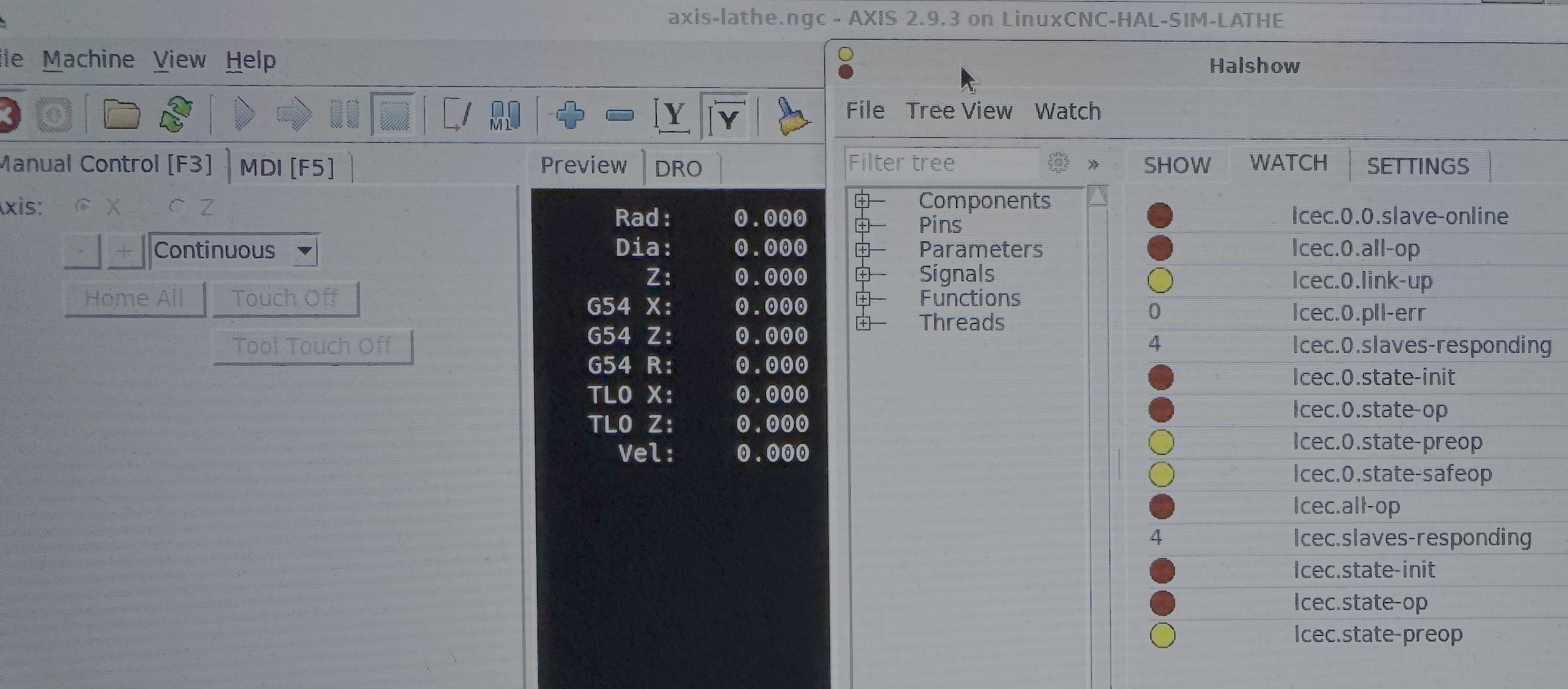

Replied by Macwolf on topic Beckhoff components crasht Linuxcnc

Beckhoff components crasht Linuxcnc

Category: EtherCAT

- Plasmanfm

- Plasmanfm

21 Oct 2024 16:10

Replied by Plasmanfm on topic G-Code Verarbeitung: Kurze Pausen zwischen Bewegungen - Wie beschleunigen?

G-Code Verarbeitung: Kurze Pausen zwischen Bewegungen - Wie beschleunigen?

Category: Deutsch

Time to create page: 0.462 seconds