Search Results (Searched for: )

- dave.franchino@gmail.com

- dave.franchino@gmail.com

29 Sep 2024 12:58

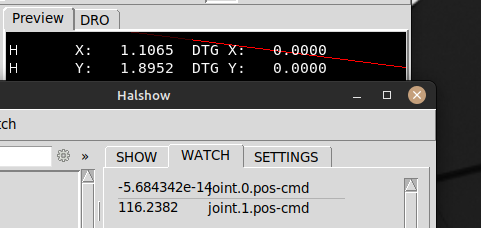

Replied by dave.franchino@gmail.com on topic Struggling with custom kinematics...

Struggling with custom kinematics...

Category: Advanced Configuration

- Sandro

- Sandro

29 Sep 2024 12:44 - 29 Sep 2024 12:45

Replied by Sandro on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- Walkahz

- Walkahz

29 Sep 2024 12:21

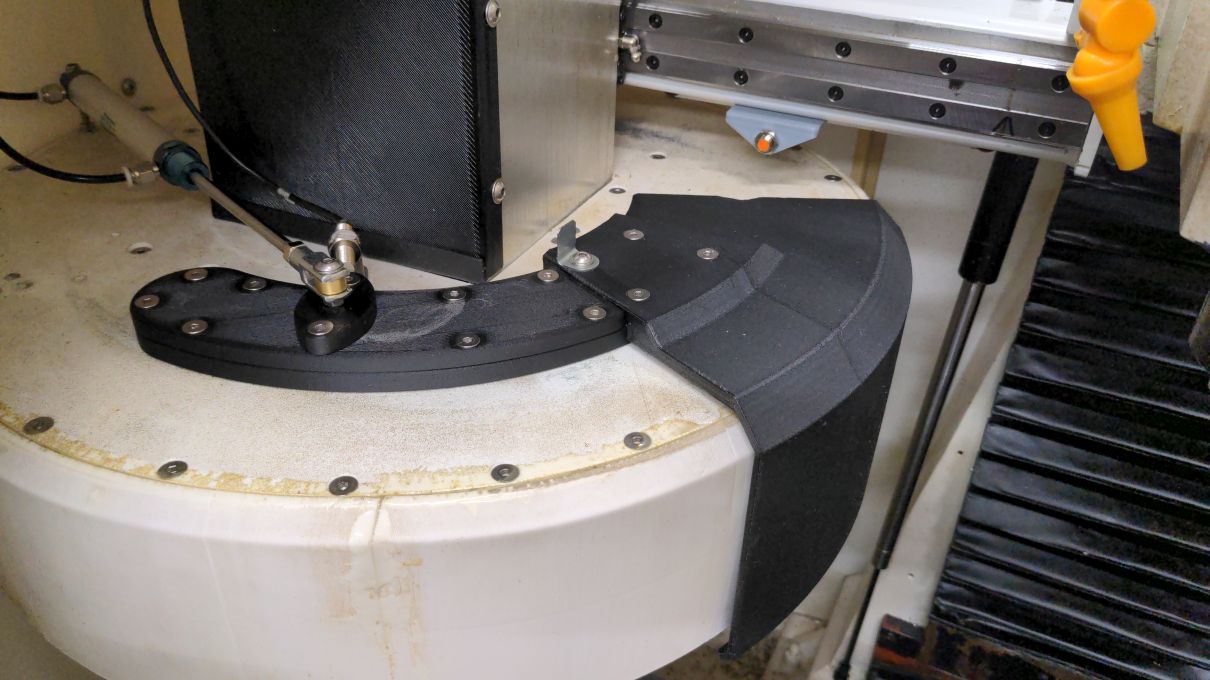

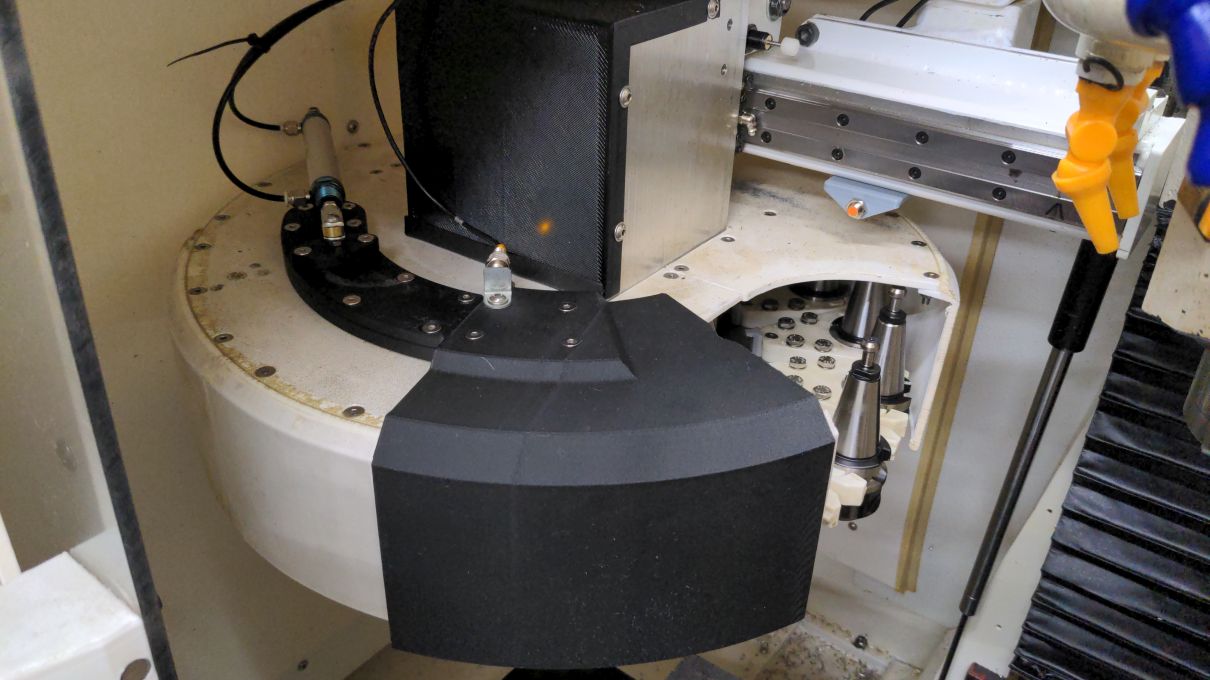

Replied by Walkahz on topic Deckel FP4 ATC Retrofit

Deckel FP4 ATC Retrofit

Category: Milling Machines

- Walkahz

- Walkahz

29 Sep 2024 12:10

Linking multiple signals/pins together was created by Walkahz

Linking multiple signals/pins together

Category: ClassicLadder

- Aciera

29 Sep 2024 11:48

Replied by Aciera on topic Struggling with custom kinematics...

Struggling with custom kinematics...

Category: Advanced Configuration

- Aciera

29 Sep 2024 11:10 - 29 Sep 2024 11:59

- gambaf

- gambaf

29 Sep 2024 10:10

- Giovanni

- Giovanni

29 Sep 2024 09:34

Replied by Giovanni on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- andreabonuc

- andreabonuc

29 Sep 2024 06:21

Replied by andreabonuc on topic Constant loss of position

Constant loss of position

Category: General LinuxCNC Questions

- rebelx

- rebelx

29 Sep 2024 05:19 - 29 Sep 2024 06:54

- pippin88

- pippin88

29 Sep 2024 05:05

- dave.franchino@gmail.com

- dave.franchino@gmail.com

29 Sep 2024 03:48

Replied by dave.franchino@gmail.com on topic Struggling with custom kinematics...

Struggling with custom kinematics...

Category: Advanced Configuration

- spumco

- spumco

29 Sep 2024 01:28

Replied by spumco on topic 3D printed stuff, showcase it here

3D printed stuff, showcase it here

Category: Additive Manufacturing

- slowpoke

- slowpoke

28 Sep 2024 23:28

Replied by slowpoke on topic Re-Home axis after joint has already been homed

Re-Home axis after joint has already been homed

Category: HAL

- PCW

28 Sep 2024 22:44

Replied by PCW on topic Constant loss of position

Constant loss of position

Category: General LinuxCNC Questions

Time to create page: 0.876 seconds