Search Results (Searched for: )

- RLA

- RLA

19 Aug 2024 14:40

Replied by RLA on topic Open Configuration tool issue

Open Configuration tool issue

Category: Configuration Tools

- royka

- royka

19 Aug 2024 14:04

Replied by royka on topic Pc reboot / 5i25(6i25) & 7i77

Pc reboot / 5i25(6i25) & 7i77

Category: Computers and Hardware

- Todd Zuercher

19 Aug 2024 14:02

Replied by Todd Zuercher on topic Beginners homing woes

Beginners homing woes

Category: Basic Configuration

- chernogorsky

- chernogorsky

19 Aug 2024 12:52

Replied by chernogorsky on topic [QTDragon] blocking in hal_manualtoolchange dialog

[QTDragon] blocking in hal_manualtoolchange dialog

Category: Qtvcp

- tommylight

19 Aug 2024 12:43

Replied by tommylight on topic Pc reboot / 5i25(6i25) & 7i77

Pc reboot / 5i25(6i25) & 7i77

Category: Computers and Hardware

- ikkuh

19 Aug 2024 12:40

- Sami

- Sami

19 Aug 2024 12:32

Replied by Sami on topic Pc reboot / 5i25(6i25) & 7i77

Pc reboot / 5i25(6i25) & 7i77

Category: Computers and Hardware

- Aciera

19 Aug 2024 12:08

- rodw

19 Aug 2024 12:06

Replied by rodw on topic Video about shielding cnc machine wiring

Video about shielding cnc machine wiring

Category: Computers and Hardware

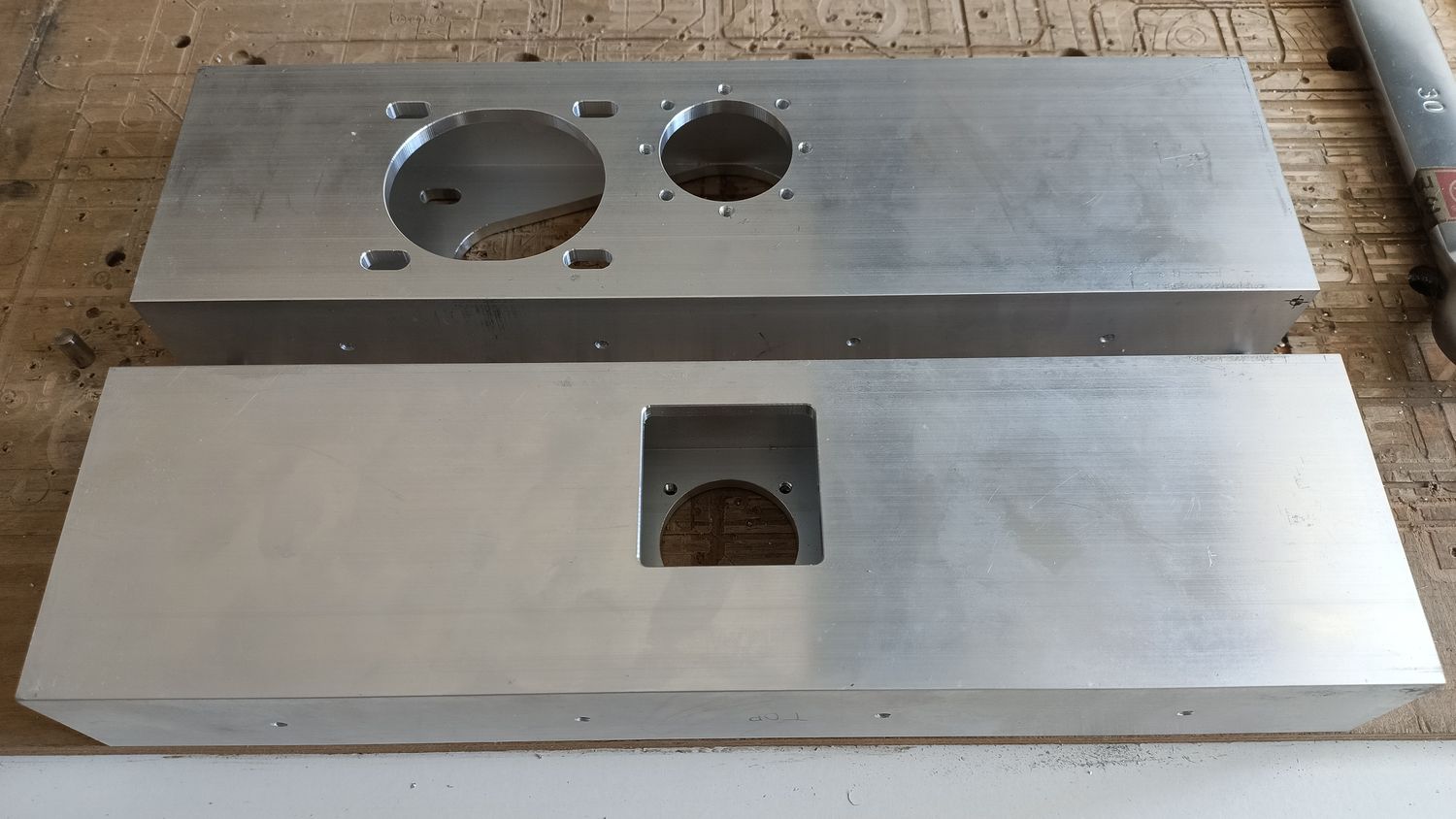

- Aciera

19 Aug 2024 11:57 - 19 Aug 2024 12:00

- Mr. Mass

19 Aug 2024 10:56 - 19 Aug 2024 10:58

- tommylight

19 Aug 2024 10:37

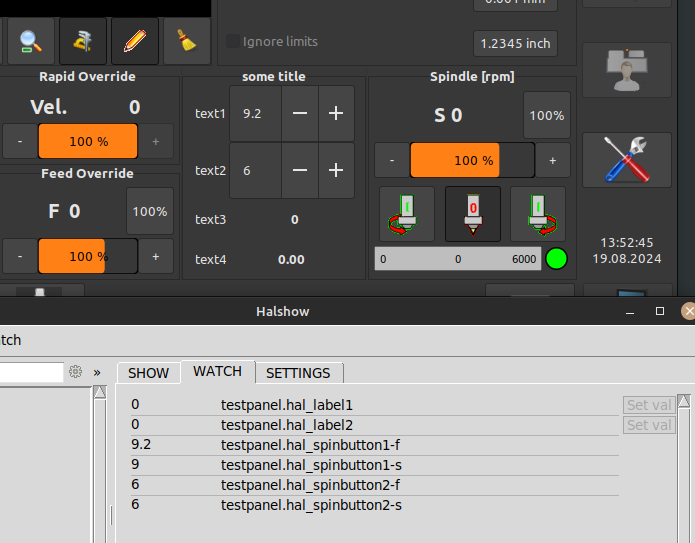

Replied by tommylight on topic Learning HAL and external offsets

Learning HAL and external offsets

Category: HAL

- MaHa

- MaHa

19 Aug 2024 10:05 - 19 Aug 2024 10:06

- DPFlex

- DPFlex

19 Aug 2024 09:46

Replied by DPFlex on topic How to setup gearbox/reducer

How to setup gearbox/reducer

Category: Basic Configuration

- TheRoslyak

19 Aug 2024 09:00

Time to create page: 0.496 seconds