Search Results (Searched for: )

- tommylight

10 Jan 2026 19:59

Replied by tommylight on topic First time with mesa - no ping but blinking user led on card

First time with mesa - no ping but blinking user led on card

Category: Driver Boards

- PCW

10 Jan 2026 19:46

- Skoudfut

- Skoudfut

10 Jan 2026 19:45

First time with mesa - no ping but blinking user led on card was created by Skoudfut

First time with mesa - no ping but blinking user led on card

Category: Driver Boards

- freemoore

- freemoore

10 Jan 2026 18:52

- endian

10 Jan 2026 18:09

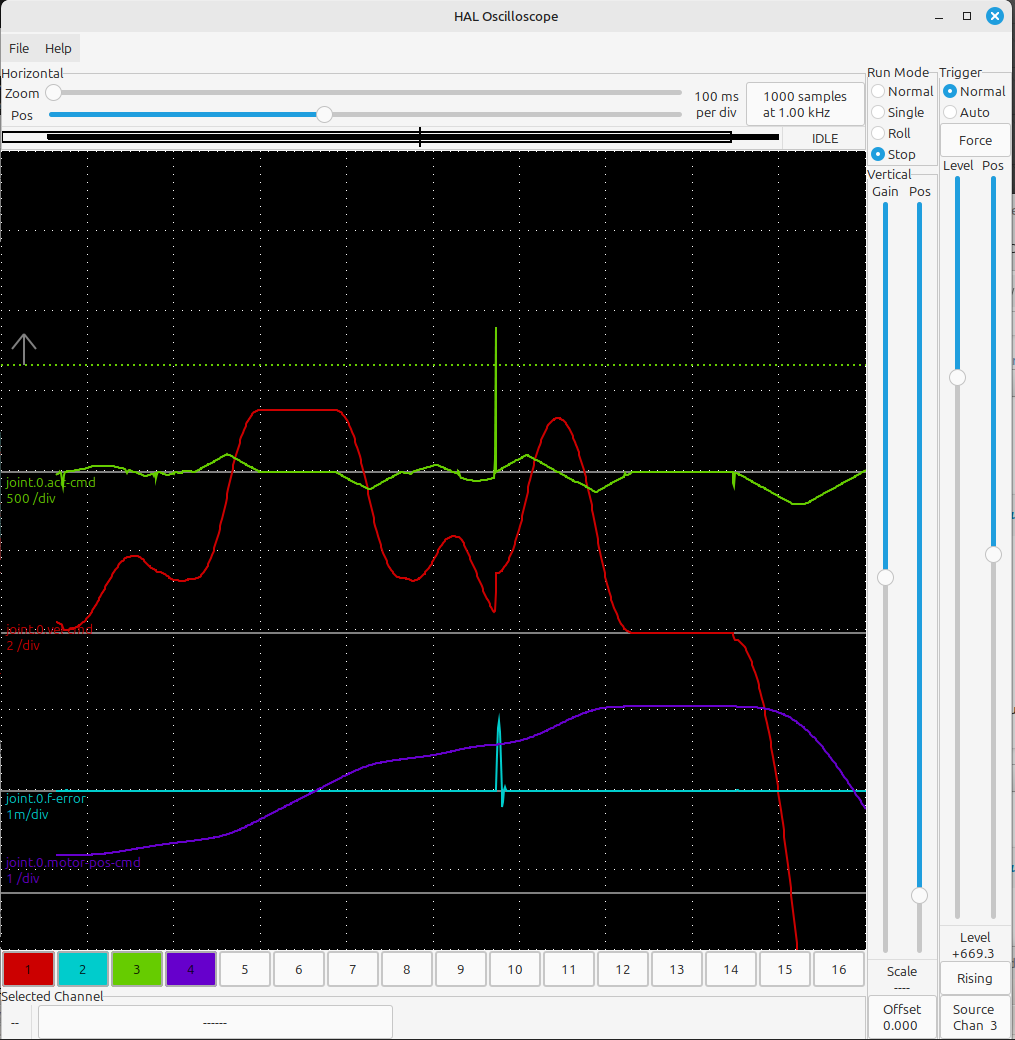

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- dusa09

- dusa09

10 Jan 2026 17:54 - 10 Jan 2026 17:54

Replied by dusa09 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Surmetall

10 Jan 2026 17:16

Replied by Surmetall on topic Announcing Deckard: StreamDeck support for LinuxCNC

Announcing Deckard: StreamDeck support for LinuxCNC

Category: Show Your Stuff

- PCW

10 Jan 2026 16:18

Replied by PCW on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- PCW

10 Jan 2026 15:46

- grandixximo

10 Jan 2026 15:17

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- freemoore

- freemoore

10 Jan 2026 15:17

- ruediger123

- ruediger123

10 Jan 2026 15:07 - 10 Jan 2026 15:13

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- tommylight

10 Jan 2026 13:57

Replied by tommylight on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- andypugh

10 Jan 2026 13:52

Replied by andypugh on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- amanker

- amanker

10 Jan 2026 13:26 - 10 Jan 2026 14:28

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

Time to create page: 0.285 seconds