Search Results (Searched for: )

- MaHa

- MaHa

30 Jan 2026 17:14

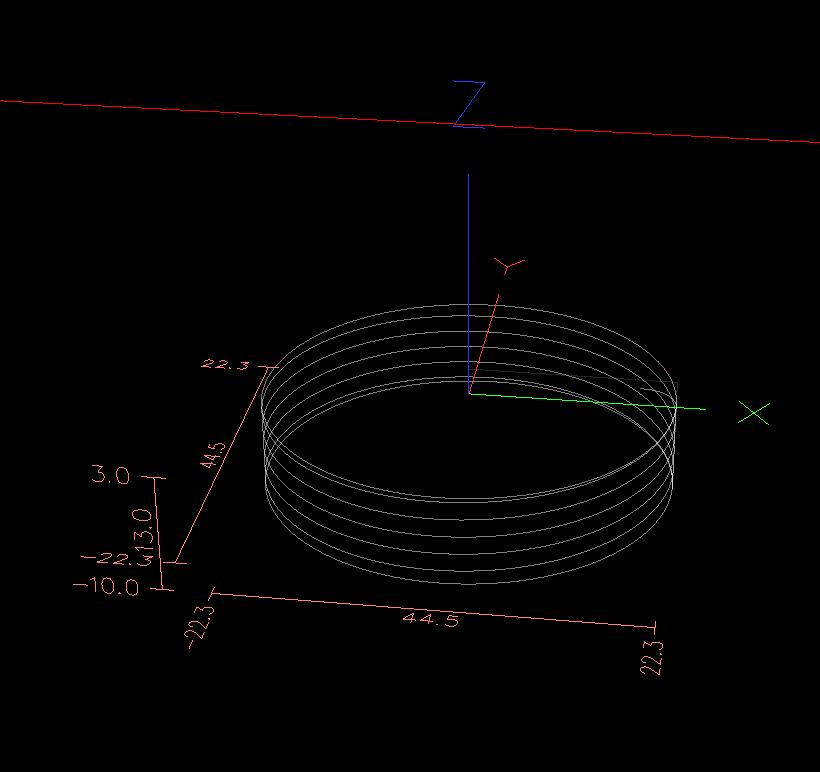

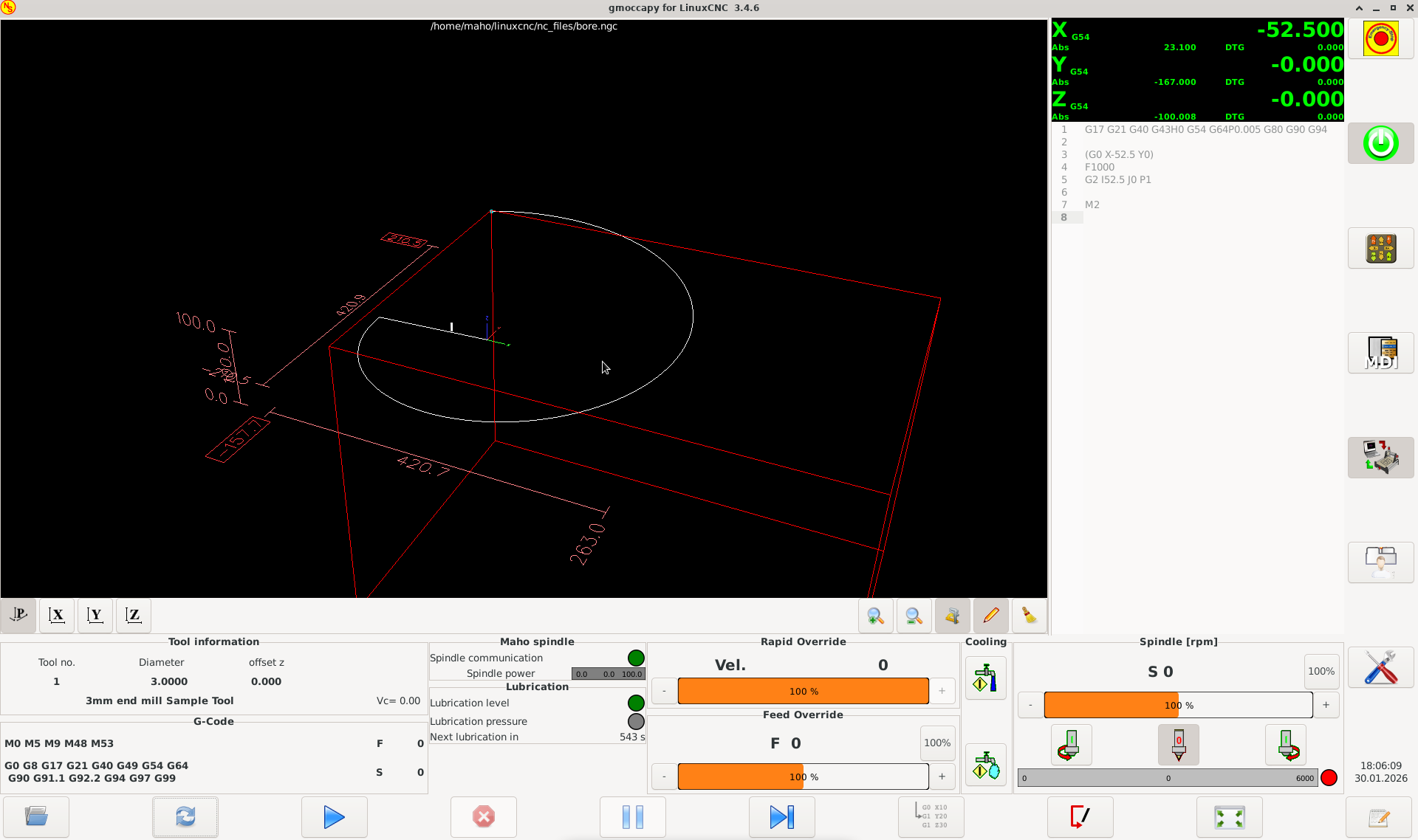

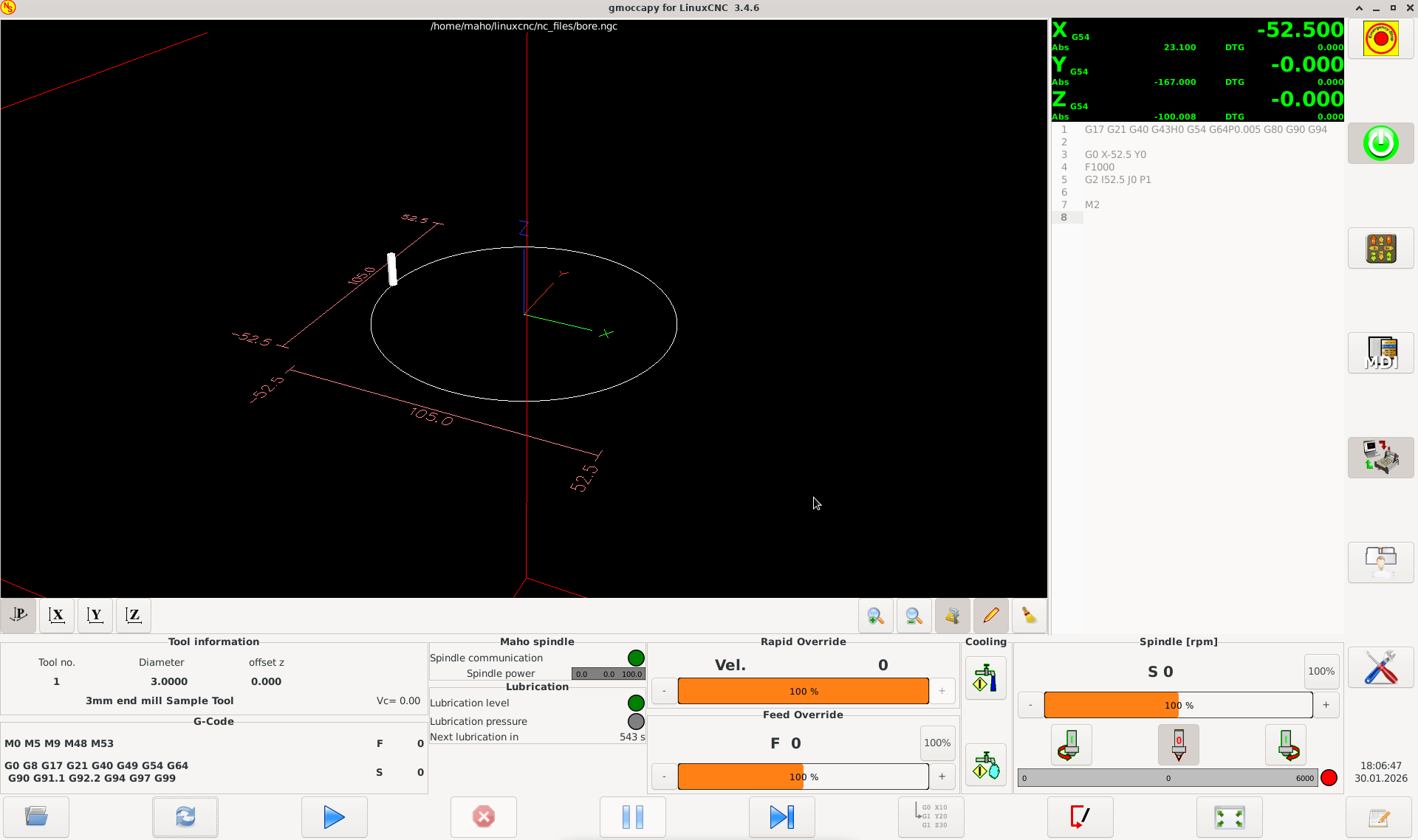

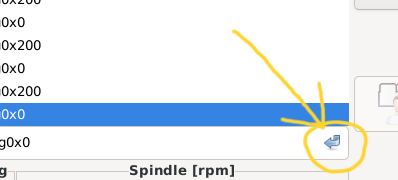

Replied by MaHa on topic Strange preview for circular arc (G2/G3)

Strange preview for circular arc (G2/G3)

Category: G&M Codes

- Finngineering

- Finngineering

30 Jan 2026 16:27

Replied by Finngineering on topic Strange preview for circular arc (G2/G3)

Strange preview for circular arc (G2/G3)

Category: G&M Codes

- dcsilvias13

- dcsilvias13

30 Jan 2026 15:22

Replied by dcsilvias13 on topic Ethercat Leadshine L6N Gantry XYYZ Config

Ethercat Leadshine L6N Gantry XYYZ Config

Category: EtherCAT

- PCW

30 Jan 2026 14:59 - 30 Jan 2026 15:00

Replied by PCW on topic OMRON Yaskawa controllers, what I/O board would you choose

OMRON Yaskawa controllers, what I/O board would you choose

Category: Driver Boards

- zz912

30 Jan 2026 14:53

- Hakan

- Hakan

30 Jan 2026 14:52 - 30 Jan 2026 14:53

Replied by Hakan on topic Lichuan 4 axis stepper need help-

Lichuan 4 axis stepper need help-

Category: EtherCAT

- amanker

- amanker

30 Jan 2026 14:11

How to update QtDragon_HD to latest version? was created by amanker

How to update QtDragon_HD to latest version?

Category: Qtvcp

- ruediger123

- ruediger123

30 Jan 2026 13:28

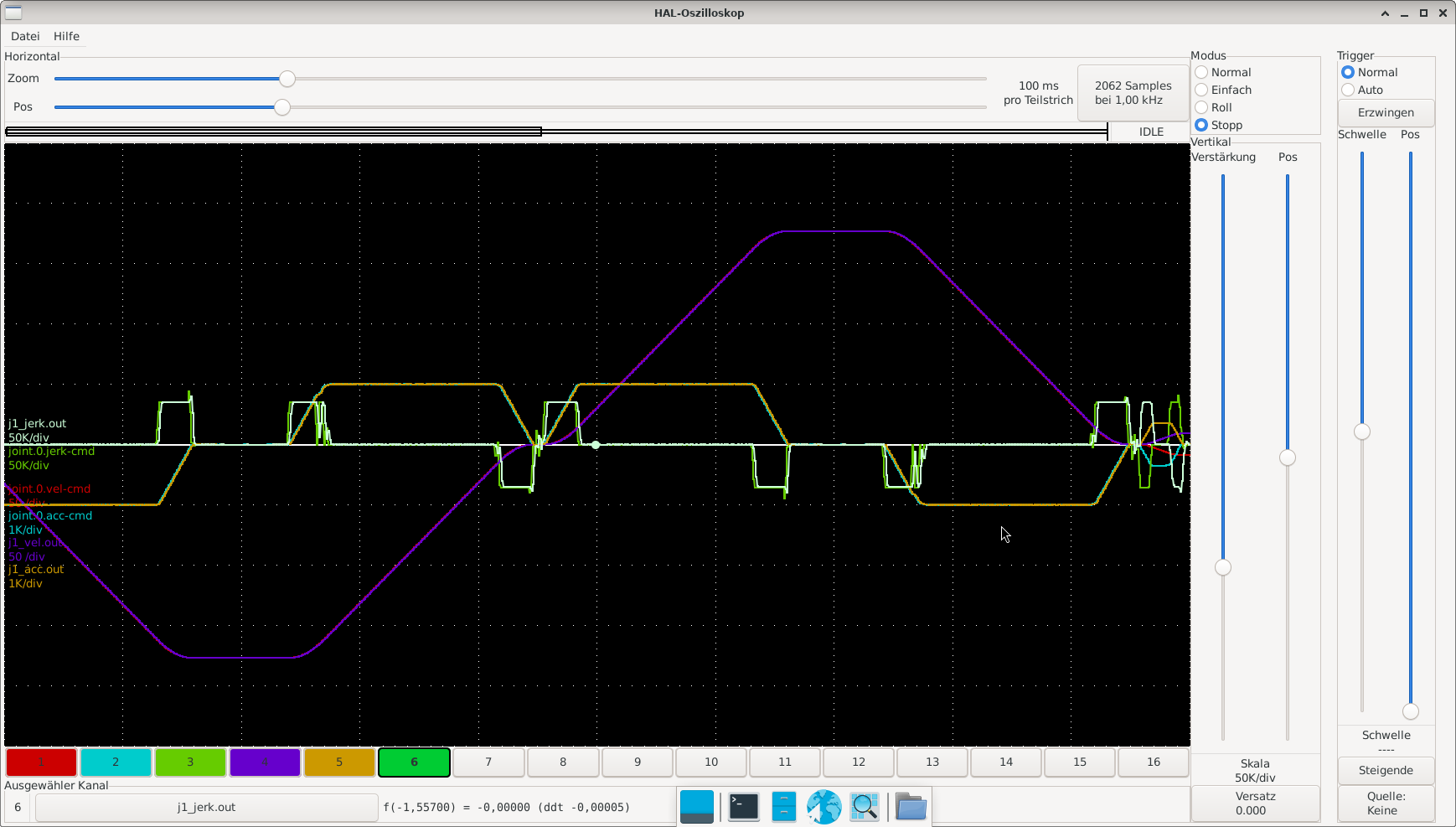

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- tommylight

30 Jan 2026 13:17

Replied by tommylight on topic How to do wiring to generate quadrature encoder signal in Mesa 7i95 board

How to do wiring to generate quadrature encoder signal in Mesa 7i95 board

Category: Driver Boards

- spumco

- spumco

30 Jan 2026 13:13

- tommylight

30 Jan 2026 13:13

Replied by tommylight on topic OMRON Yaskawa controllers, what I/O board would you choose

OMRON Yaskawa controllers, what I/O board would you choose

Category: Driver Boards

- tommylight

30 Jan 2026 13:11

- grandixximo

30 Jan 2026 13:05

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- BertaA

- BertaA

30 Jan 2026 12:57 - 30 Jan 2026 17:46

- ruediger123

- ruediger123

30 Jan 2026 12:22

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

Time to create page: 0.349 seconds