Search Results (Searched for: )

- Hakan

- Hakan

04 Mar 2025 07:10

Replied by Hakan on topic Fusion 360 post processor file for Plamac

Fusion 360 post processor file for Plamac

Category: Plasmac

- meister

- meister

04 Mar 2025 06:47

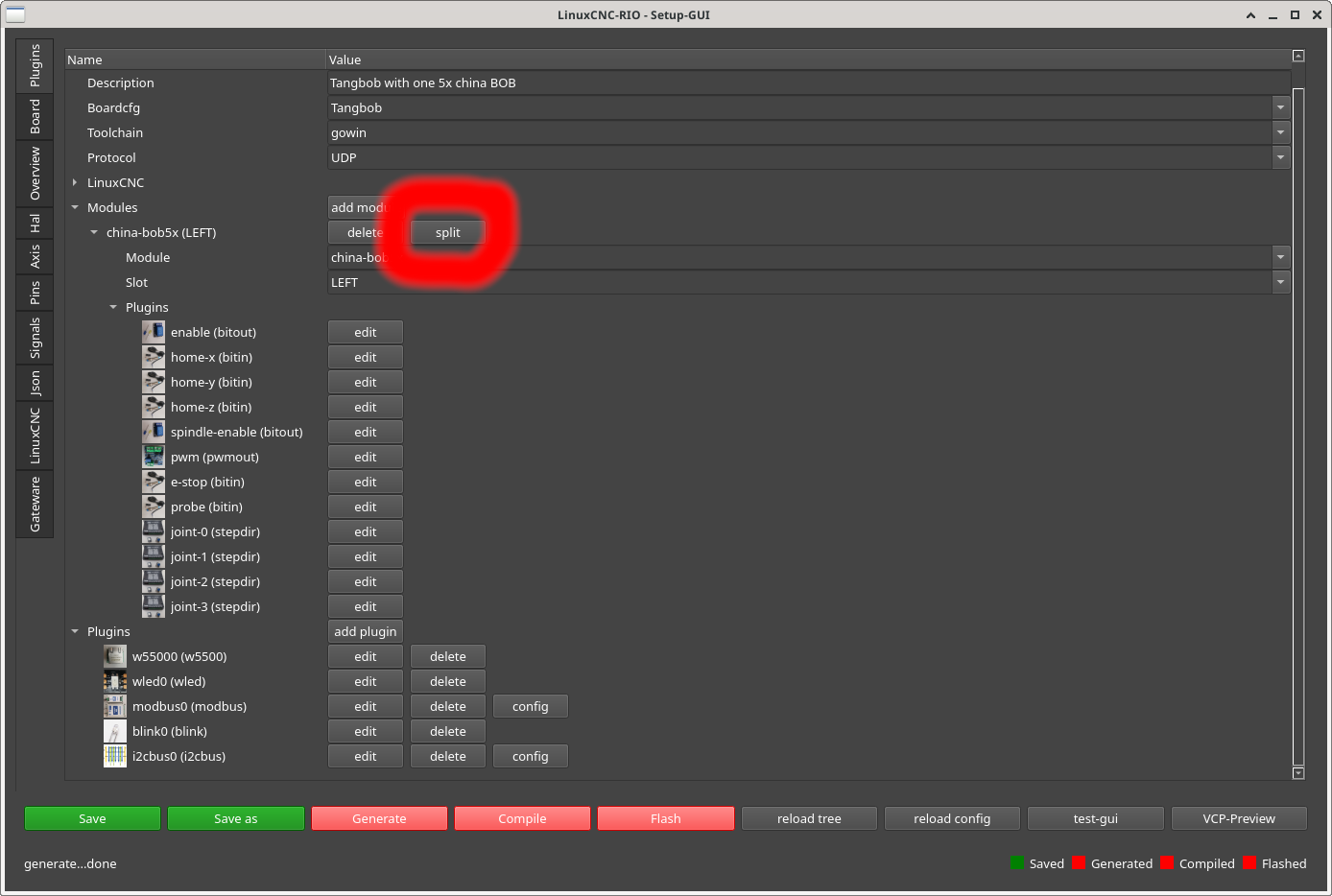

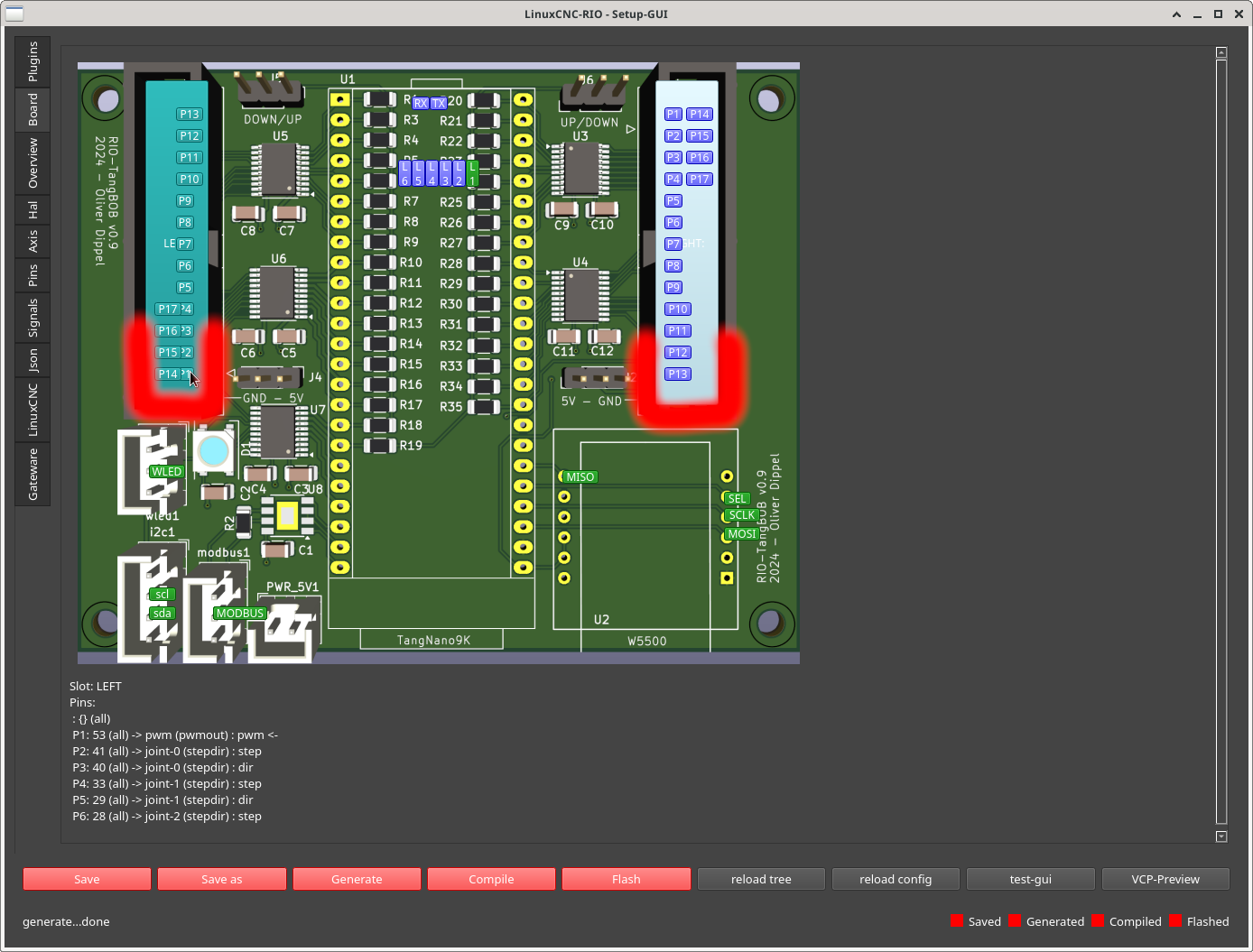

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- ErwinCNC

- ErwinCNC

04 Mar 2025 06:39 - 06 Mar 2025 19:05

- cmorley

- cmorley

04 Mar 2025 06:35

Replied by cmorley on topic How to open QT ui file in LinuxCNC

How to open QT ui file in LinuxCNC

Category: Qtvcp

- ihavenofish

- ihavenofish

04 Mar 2025 06:25

Replied by ihavenofish on topic New ethercat / probe basic control for minimonster

New ethercat / probe basic control for minimonster

Category: CNC Machines

- kzali

- kzali

04 Mar 2025 06:18

- NTULINUX

04 Mar 2025 06:17

Replied by NTULINUX on topic LinuxCNC on Intel Clear Linux

LinuxCNC on Intel Clear Linux

Category: Installing LinuxCNC

- behai

- behai

04 Mar 2025 04:31

- gwond

- gwond

04 Mar 2025 03:15

Replied by gwond on topic Fusion 360 post processor file for Plamac

Fusion 360 post processor file for Plamac

Category: Plasmac

- rebelx

- rebelx

04 Mar 2025 03:04

Replied by rebelx on topic LinuxCNC on Intel Clear Linux

LinuxCNC on Intel Clear Linux

Category: Installing LinuxCNC

- rebelx

- rebelx

04 Mar 2025 02:54

Replied by rebelx on topic LinuxCNC on Intel Clear Linux

LinuxCNC on Intel Clear Linux

Category: Installing LinuxCNC

- jyeomans

- jyeomans

04 Mar 2025 01:54

- JohnnyCNC

04 Mar 2025 00:41 - 04 Mar 2025 00:43

- M4MazakUser

- M4MazakUser

04 Mar 2025 00:02

Replied by M4MazakUser on topic irregular machining

irregular machining

Category: General LinuxCNC Questions

- Ismacr63

- Ismacr63

03 Mar 2025 22:26

irregular machining was created by Ismacr63

irregular machining

Category: General LinuxCNC Questions

Time to create page: 0.390 seconds