Search Results (Searched for: )

- robh

- robh

12 Jan 2025 11:53

- rodw

12 Jan 2025 11:36

- HansU

12 Jan 2025 11:34

Replied by HansU on topic Problem with macro in MDI mode

Problem with macro in MDI mode

Category: Gmoccapy

- rodw

12 Jan 2025 11:33

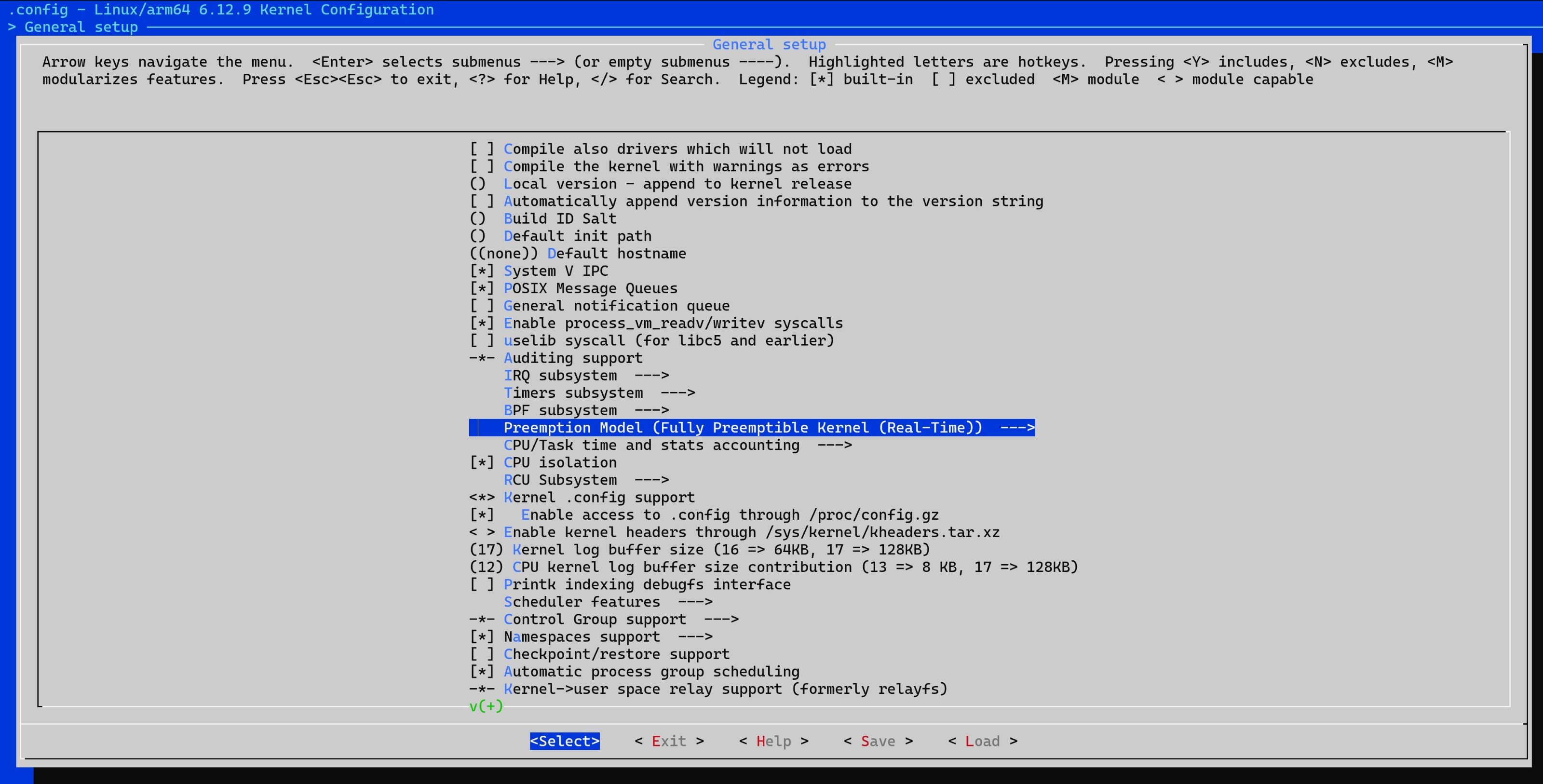

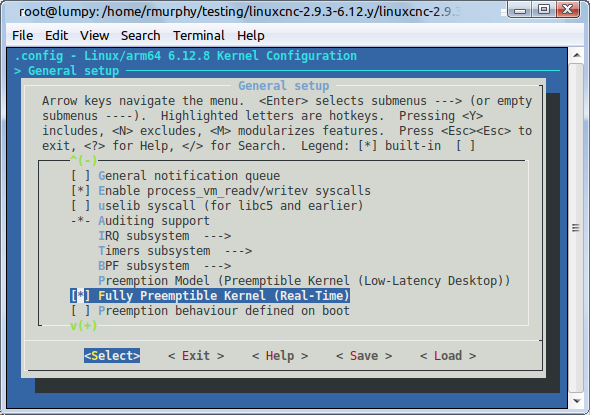

Replied by rodw on topic Real-time kerel not detected on patched 6.12

Real-time kerel not detected on patched 6.12

Category: General LinuxCNC Questions

- HansU

12 Jan 2025 11:32 - 12 Jan 2025 11:32

Replied by HansU on topic Change color of SpeedControl widget using css

Change color of SpeedControl widget using css

Category: Gmoccapy

- HansU

- royka

- royka

12 Jan 2025 11:11 - 12 Jan 2025 11:20

Replied by royka on topic Real-time kerel not detected on patched 6.12

Real-time kerel not detected on patched 6.12

Category: General LinuxCNC Questions

- HansU

12 Jan 2025 11:04

Replied by HansU on topic Unwanted actions with a touch screen

Unwanted actions with a touch screen

Category: Gmoccapy

- blazini36

- blazini36

12 Jan 2025 11:03

Replied by blazini36 on topic Flex GUI Stylesheet Builder

Flex GUI Stylesheet Builder

Category: Flex GUI

- HansU

12 Jan 2025 11:02

Replied by HansU on topic Duplicate settings in Pref File

Duplicate settings in Pref File

Category: Gmoccapy

- JT

12 Jan 2025 10:43

- Cant do this anymore bye all

12 Jan 2025 10:36

Replied by Cant do this anymore bye all on topic Real-time kerel not detected on patched 6.12

Real-time kerel not detected on patched 6.12

Category: General LinuxCNC Questions

- JT

12 Jan 2025 10:35

- Cant do this anymore bye all

12 Jan 2025 10:11

Replied by Cant do this anymore bye all on topic RPi 5 with 6.12 PREEMPT_RT = Using POSIX non-realtime

RPi 5 with 6.12 PREEMPT_RT = Using POSIX non-realtime

Category: Installing LinuxCNC

- Aciera

12 Jan 2025 10:06

Time to create page: 1.963 seconds