Search Results (Searched for: )

- tommylight

04 Dec 2025 14:16

Replied by tommylight on topic Qtplasmac- Auto Z axis movement not happening with thc proma 150

Qtplasmac- Auto Z axis movement not happening with thc proma 150

Category: Plasmac

- jaro_p

04 Dec 2025 13:48 - 04 Dec 2025 14:07

Replied by jaro_p on topic Changes in configuration files generated in pncconfig for 7i76 to 7i78

Changes in configuration files generated in pncconfig for 7i76 to 7i78

Category: PnCConf Wizard

- Nathan40

- Nathan40

04 Dec 2025 13:25

Replied by Nathan40 on topic Qtplasmac- Auto Z axis movement not happening with thc proma 150

Qtplasmac- Auto Z axis movement not happening with thc proma 150

Category: Plasmac

- tommylight

04 Dec 2025 13:20

Replied by tommylight on topic Qtplasmac- Auto Z axis movement not happening with thc proma 150

Qtplasmac- Auto Z axis movement not happening with thc proma 150

Category: Plasmac

- Nathan40

- Nathan40

04 Dec 2025 13:07

Qtplasmac- Auto Z axis movement not happening with thc proma 150 was created by Nathan40

Qtplasmac- Auto Z axis movement not happening with thc proma 150

Category: Plasmac

- tommylight

04 Dec 2025 12:29

Replied by tommylight on topic Hybrid Manual/Stepper Control

Hybrid Manual/Stepper Control

Category: General LinuxCNC Questions

- tommylight

04 Dec 2025 12:26

Replied by tommylight on topic Changes in configuration files generated in pncconfig for 7i76 to 7i78

Changes in configuration files generated in pncconfig for 7i76 to 7i78

Category: PnCConf Wizard

- timo

- timo

04 Dec 2025 12:14

Replied by timo on topic Hybrid Manual/Stepper Control

Hybrid Manual/Stepper Control

Category: General LinuxCNC Questions

- Mr. Mass

04 Dec 2025 12:14

- JT

04 Dec 2025 10:57

- voltaicsca

- voltaicsca

04 Dec 2025 10:41

Hybrid Manual/Stepper Control was created by voltaicsca

Hybrid Manual/Stepper Control

Category: General LinuxCNC Questions

- jaro_p

04 Dec 2025 08:14

- Aciera

04 Dec 2025 07:19 - 04 Dec 2025 09:01

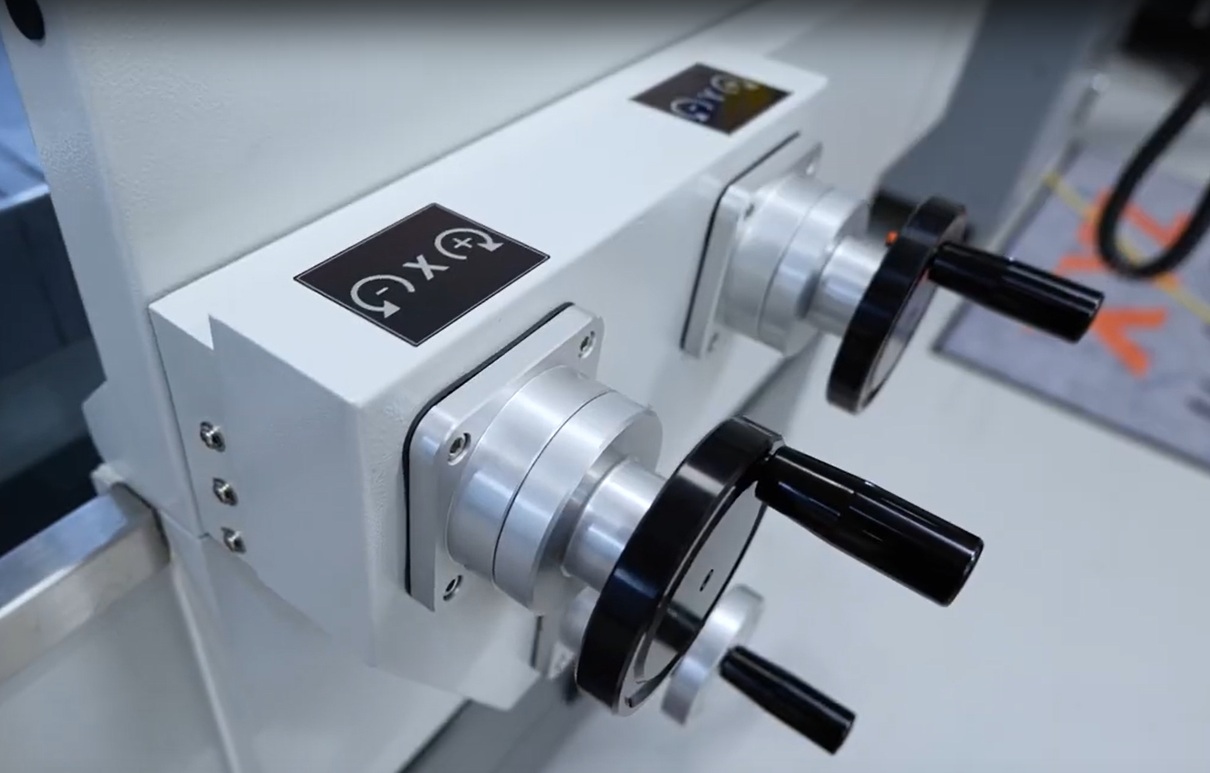

Replied by Aciera on topic Ursviken Pullmax Optima 130 press brake retrofit with 4 axis backgage

Ursviken Pullmax Optima 130 press brake retrofit with 4 axis backgage

Category: Show Your Stuff

- masawee

- masawee

04 Dec 2025 07:16

Replied by masawee on topic Linuxcnc Image for Raspberry Pi 3

Linuxcnc Image for Raspberry Pi 3

Category: General LinuxCNC Questions

- masawee

- masawee

04 Dec 2025 07:04

Replied by masawee on topic Linuxcnc Image for Raspberry Pi 3

Linuxcnc Image for Raspberry Pi 3

Category: General LinuxCNC Questions

Time to create page: 0.218 seconds