Search Results (Searched for: )

- NWE

- NWE

12 Dec 2025 19:52 - 12 Dec 2025 21:34

- Masiwood123

12 Dec 2025 19:45

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Fastfred

- Fastfred

12 Dec 2025 19:22

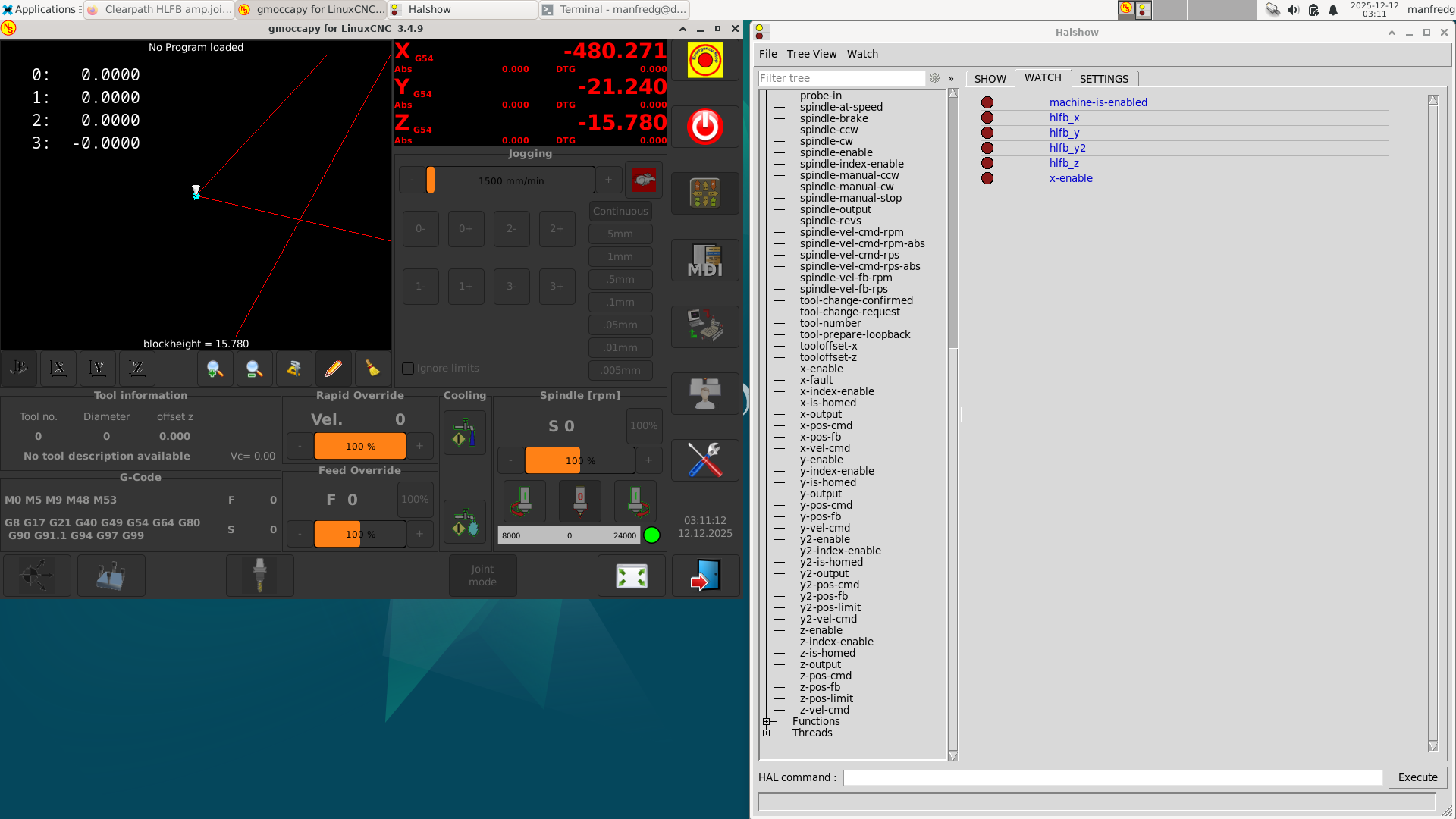

Replied by Fastfred on topic Clearpath HLFB amp.joint.delay

Clearpath HLFB amp.joint.delay

Category: HAL

- T_D

- T_D

12 Dec 2025 19:13

Replied by T_D on topic Mesa konfiguration Maho 500 W4

Mesa konfiguration Maho 500 W4

Category: Driver Boards

- Masiwood123

12 Dec 2025 18:36

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

freelancer needed to create a routine for ATC tool change (rackchange)

Category: Advanced Configuration

- gravedigger

- gravedigger

12 Dec 2025 18:31

Replied by gravedigger on topic stepgen maxvel too big and SRO problem

stepgen maxvel too big and SRO problem

Category: Gmoccapy

- Ismacr63

- Ismacr63

12 Dec 2025 18:25

- Masiwood123

12 Dec 2025 17:14 - 12 Dec 2025 17:29

Replied by Masiwood123 on topic freelancer needed to create a routine for ATC tool change (rackchange)

freelancer needed to create a routine for ATC tool change (rackchange)

Category: Advanced Configuration

- tommylight

12 Dec 2025 16:12

- tommylight

12 Dec 2025 16:08

- tommylight

12 Dec 2025 16:05

Replied by tommylight on topic Mesa konfiguration Maho 500 W4

Mesa konfiguration Maho 500 W4

Category: Driver Boards

- Ismacr63

- Ismacr63

12 Dec 2025 16:03

- tommylight

12 Dec 2025 15:59

Replied by tommylight on topic freelancer needed to create a routine for ATC tool change (rackchange)

freelancer needed to create a routine for ATC tool change (rackchange)

Category: Advanced Configuration

- Hakan

- Hakan

12 Dec 2025 15:49

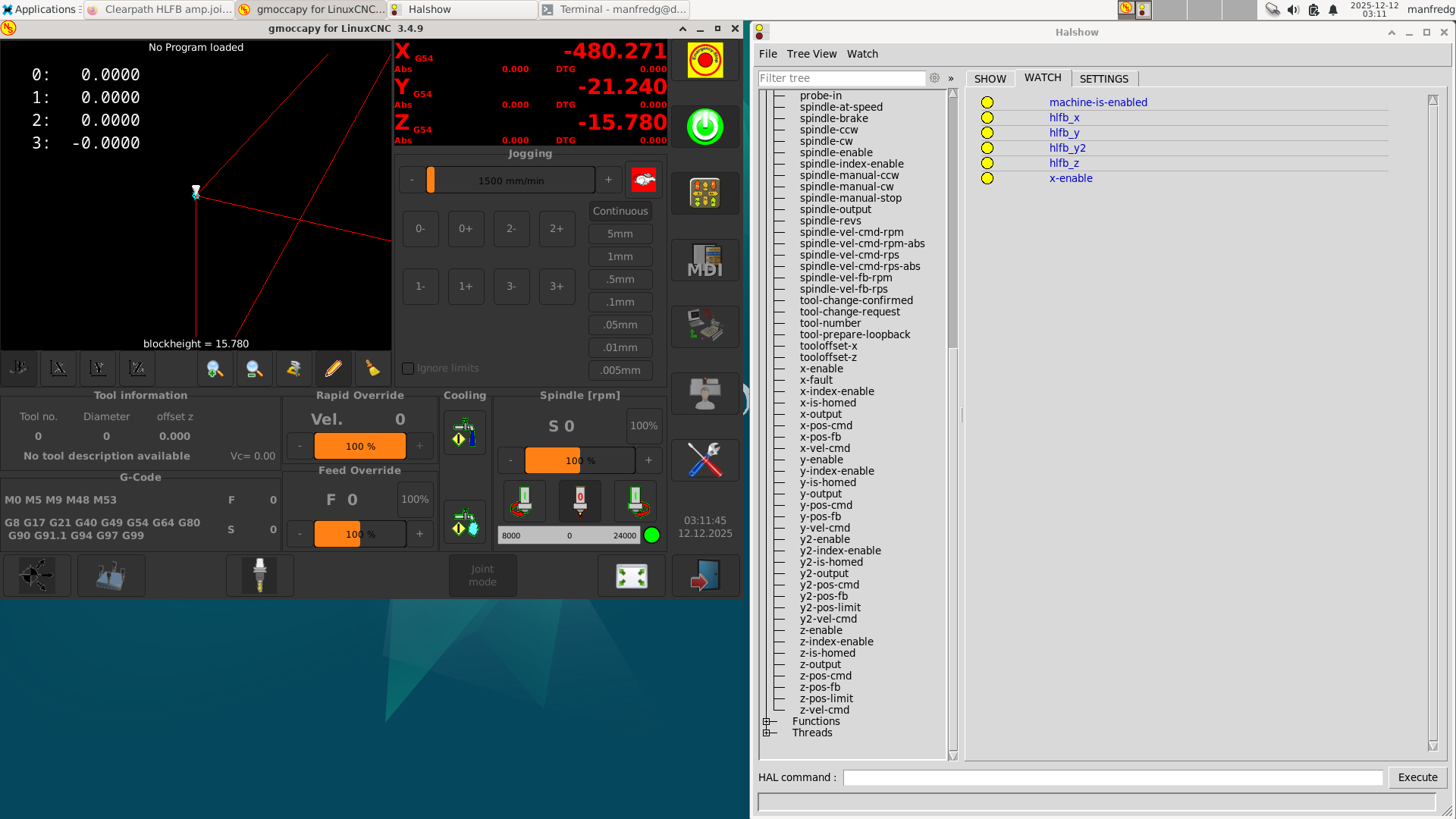

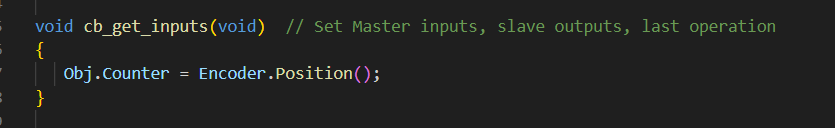

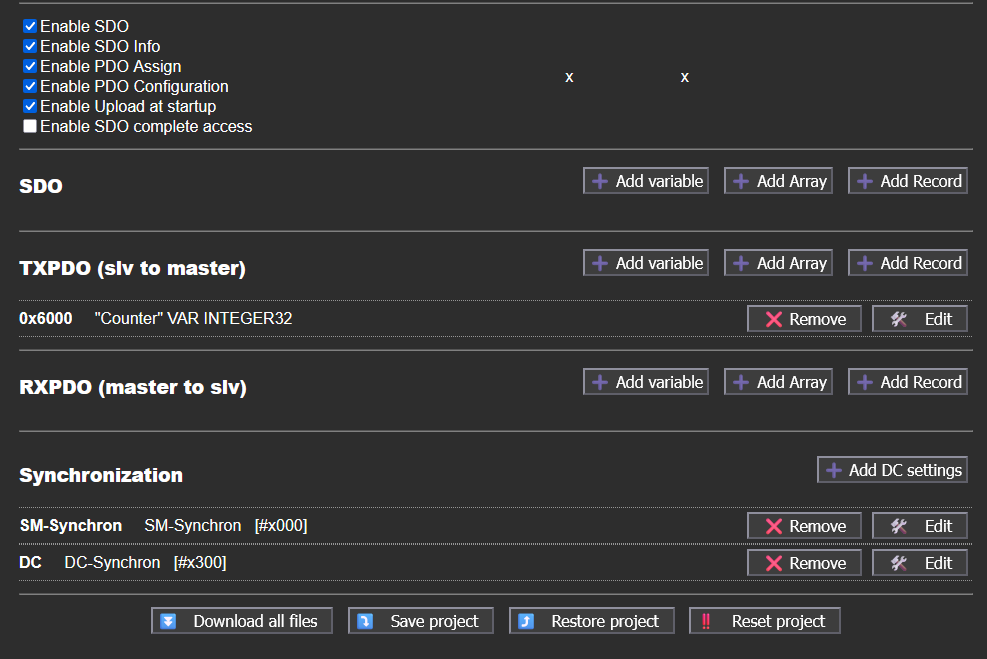

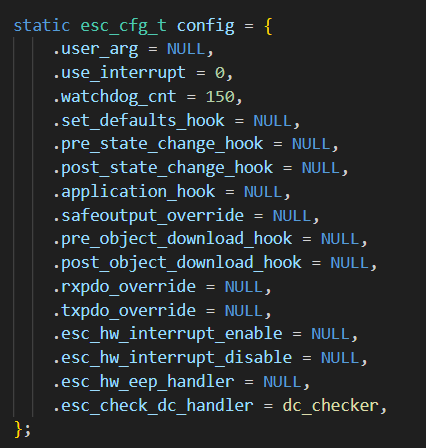

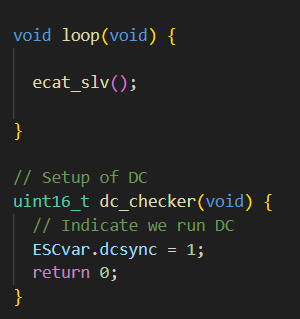

Replied by Hakan on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

- Hakan

- Hakan

12 Dec 2025 15:26 - 12 Dec 2025 15:32

Replied by Hakan on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

Time to create page: 0.275 seconds