Search Results (Searched for: )

- Cant do this anymore bye all

28 Jul 2024 22:45

Replied by Cant do this anymore bye all on topic Keyboard gets unresponsive from time to time

Keyboard gets unresponsive from time to time

Category: General LinuxCNC Questions

ssh into the debian pc when the keyboard disconnects and run dmesg, this should give an idea of what is happening.

- rdtsc

28 Jul 2024 22:38 - 28 Jul 2024 22:51

Replied by rdtsc on topic 2.9.3 ISO Issue

2.9.3 ISO Issue

Category: Installing LinuxCNC

I think I was able to update 2.9.2 to 2.9.3 successfully using sudo apt update. However, today I'm getting a key error:

This key error is really odd because that repo is not listed in /etc/apt/sources.list. Oh wait, found it under /etc/apt/sources.list.d/ighvh.sources. Seems it may have something to do with our EtherCAT? build.opensuse.org/projects/science:EtherLab/prjconf

Looking further, they have a page for the key: build.opensuse.org/projects/science:EtherLab/signing_keys and a link there to download an "armored version" of a supposedly newer key (says it now expires in two years.)

Thinking maybe if that key were updated, things would improve, researched how to add it and did the following:

As a temporary work-around (I'm not using EtherCAT), `sudo mv /etc/apt/sources.list.d/ighvh.sources /etc/apt/sources.list.d/ighvh.sources.disabled` will disable that source and the resulting error. But this should be investigated properly for the next .iso (if it hasn't already.)

Get:7 http://download.opensuse.org/repositories/science:/EtherLab/Debian_12 ./ InRelease [1,575 B]

Hit:8 https://www.linuxcnc.org bookworm InRelease

Err:7 http://download.opensuse.org/repositories/science:/EtherLab/Debian_12 ./ InRelease

The following signatures were invalid: EXPKEYSIG A94819A7CB97A204 science:EtherLab OBS Project <science:EtherLab@build.opensuse.org>

Fetched 1,575 B in 3s (564 B/s)

Reading package lists... Done

Building dependency tree... Done

Reading state information... Done

All packages are up to date.

W: An error occurred during the signature verification. The repository is not updated and the previous index files will be used. GPG error: http://download.opensuse.org/repositories/science:/EtherLab/Debian_12 ./ InRelease: The following signatures were invalid: EXPKEYSIG A94819A7CB97A204 science:EtherLab OBS Project <science:EtherLab@build.opensuse.org>

W: Failed to fetch http://download.opensuse.org/repositories/science:/EtherLab/Debian_12/./InRelease The following signatures were invalid: EXPKEYSIG A94819A7CB97A204 science:EtherLab OBS Project <science:EtherLab@build.opensuse.org>

W: Some index files failed to download. They have been ignored, or old ones used instead.This key error is really odd because that repo is not listed in /etc/apt/sources.list. Oh wait, found it under /etc/apt/sources.list.d/ighvh.sources. Seems it may have something to do with our EtherCAT? build.opensuse.org/projects/science:EtherLab/prjconf

Looking further, they have a page for the key: build.opensuse.org/projects/science:EtherLab/signing_keys and a link there to download an "armored version" of a supposedly newer key (says it now expires in two years.)

Thinking maybe if that key were updated, things would improve, researched how to add it and did the following:

1. Downloaded the latest `science_EtherLab_key.gpg` to `~/Downloads`

2. cd there, then `gpg --dearmor science_EtherLab_key.gpg`, which created a `science_EtherLab_key.gpg.gpg` file.

3. `su` to temporarly be root, do `cp science_EtherLab_key.gpg.gpg /usr/share/keyrings/etherlab-archive-keyring.gpg` which copies the file into the appropriate system folder.

4. `exit` to quit root. Try `sudo apt update` again: nope, keysig still invalid.As a temporary work-around (I'm not using EtherCAT), `sudo mv /etc/apt/sources.list.d/ighvh.sources /etc/apt/sources.list.d/ighvh.sources.disabled` will disable that source and the resulting error. But this should be investigated properly for the next .iso (if it hasn't already.)

- Lpkkk

- Lpkkk

28 Jul 2024 22:22

Replied by Lpkkk on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Thank you but I've already followed that, it was very helpful . Unfortunately There is no word about connection timeout. I've ordered rs232 to usb converter to have a look what is really going on with my board, it should be here tomorrow, hopefully nvem will tell me something more. Meanwhile if anyone had similar issue or know how to fix it, please share

- my1987toyota

28 Jul 2024 22:11 - 29 Jul 2024 10:13

Replied by my1987toyota on topic 7i96 non S PWM on an output possible?

7i96 non S PWM on an output possible?

Category: Driver Boards

ok below are my current HAL, INI, and PYVCP files for the foam cutter.

the HAL file

[/code][/code][/code]

the HAL file

# Generated by PNCconf at Wed Jul 17 17:05:42 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=0xxxxxxx"

loadrt pid names=pid.x,pid.y,pid.u,pid.v,pid.a,pid.s

loadrt pwmgen output_type=0

addf [HMOT](CARD0).read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.u.do-pid-calcs servo-thread

addf pid.v.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf [HMOT](CARD0).write servo-thread

addf pwmgen.update servo-thread

addf pwmgen.make-pulses servo-thread

setp [HMOT](CARD0).dpll.01.timer-us -50

setp [HMOT](CARD0).stepgen.timer-number 1

setp [HMOT](CARD0).watchdog.timeout_ns 5000000

setp pwmgen.0.dither-pwm true

setp pwmgen.0.pwm-freq 20

setp pwmgen.0.scale 100 # Change to your spindle’s top speed in RPM

# external output signals

# --- WIRE-OUTPUT-PIN ---

net spindle-speed-cmd spindle.0.speed-out => pwmgen.0.value

net spindle-on spindle.0.on => pwmgen.0.enable

net spindle-pwm pwmgen.0.pwm => [HMOT](CARD0).ssr.00.out-05

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= [HMOT](CARD0).gpio.000.in_not

# --- HOME-X ---

net home-x <= [HMOT](CARD0).gpio.001.in

# --- HOME-Y ---

net home-y <= [HMOT](CARD0).gpio.002.in

# --- HOME-U ---

net home-U <= [HMOT](CARD0).gpio.003.in

# --- HOME-V ---

net home-V <= [HMOT](CARD0).gpio.004.in

# --- HOME-A ---

#net home-A <= [HMOT](CARD0).gpio.005.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp [HMOT](CARD0).stepgen.00.dirhold [JOINT_0]DIRHOLD

setp [HMOT](CARD0).stepgen.00.steplen [JOINT_0]STEPLEN

setp [HMOT](CARD0).stepgen.00.stepspace [JOINT_0]STEPSPACE

setp [HMOT](CARD0).stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp [HMOT](CARD0).stepgen.00.step_type 0

setp [HMOT](CARD0).stepgen.00.control-type 1

setp [HMOT](CARD0).stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => [HMOT](CARD0).stepgen.00.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.00.enable

# ---setup home / limit switch signals---

#net x-home-sw => joint.0.home-sw-in

net x-home => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp [HMOT](CARD0).stepgen.01.dirhold [JOINT_1]DIRHOLD

setp [HMOT](CARD0).stepgen.01.steplen [JOINT_1]STEPLEN

setp [HMOT](CARD0).stepgen.01.stepspace [JOINT_1]STEPSPACE

setp [HMOT](CARD0).stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp [HMOT](CARD0).stepgen.01.step_type 0

setp [HMOT](CARD0).stepgen.01.control-type 1

setp [HMOT](CARD0).stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => [HMOT](CARD0).stepgen.01.velocity-cmd

net y-pos-fb <= [HMOT](CARD0).stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => [HMOT](CARD0).stepgen.01.enable

# ---setup home / limit switch signals---

#net y-home-sw => joint.1.home-sw-in

net home-y => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS U JOINT 2

#*******************

setp pid.u.Pgain [JOINT_2]P

setp pid.u.Igain [JOINT_2]I

setp pid.u.Dgain [JOINT_2]D

setp pid.u.bias [JOINT_2]BIAS

setp pid.u.FF0 [JOINT_2]FF0

setp pid.u.FF1 [JOINT_2]FF1

setp pid.u.FF2 [JOINT_2]FF2

setp pid.u.deadband [JOINT_2]DEADBAND

setp pid.u.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.u.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.u.maxerror 0.012700

net u-index-enable => pid.u.index-enable

net u-enable => pid.u.enable

net u-pos-cmd => pid.u.command

net u-pos-fb => pid.u.feedback

net u-output <= pid.u.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp [HMOT](CARD0).stepgen.02.dirhold [JOINT_2]DIRHOLD

setp [HMOT](CARD0).stepgen.02.steplen [JOINT_2]STEPLEN

setp [HMOT](CARD0).stepgen.02.stepspace [JOINT_2]STEPSPACE

setp [HMOT](CARD0).stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp [HMOT](CARD0).stepgen.02.step_type 0

setp [HMOT](CARD0).stepgen.02.control-type 1

setp [HMOT](CARD0).stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net u-pos-cmd <= joint.2.motor-pos-cmd

net u-vel-cmd <= joint.2.vel-cmd

net u-output => [HMOT](CARD0).stepgen.02.velocity-cmd

net u-pos-fb <= [HMOT](CARD0).stepgen.02.position-fb

net u-pos-fb => joint.2.motor-pos-fb

net u-enable <= joint.2.amp-enable-out

net u-enable => [HMOT](CARD0).stepgen.02.enable

# ---setup home / limit switch signals---

#net u-home-sw => joint.2.home-sw-in

net home-u => joint.2.home-sw-in

net u-neg-limit => joint.2.neg-lim-sw-in

net u-pos-limit => joint.2.pos-lim-sw-in

#*******************

# AXIS V JOINT 3

#*******************

setp pid.v.Pgain [JOINT_3]P

setp pid.v.Igain [JOINT_3]I

setp pid.v.Dgain [JOINT_3]D

setp pid.v.bias [JOINT_3]BIAS

setp pid.v.FF0 [JOINT_3]FF0

setp pid.v.FF1 [JOINT_3]FF1

setp pid.v.FF2 [JOINT_3]FF2

setp pid.v.deadband [JOINT_3]DEADBAND

setp pid.v.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.v.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.v.maxerror 0.012700

net v-index-enable => pid.v.index-enable

net v-enable => pid.v.enable

net v-pos-cmd => pid.v.command

net v-pos-fb => pid.v.feedback

net v-output <= pid.v.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.03.dirsetup [JOINT_3]DIRSETUP

setp [HMOT](CARD0).stepgen.03.dirhold [JOINT_3]DIRHOLD

setp [HMOT](CARD0).stepgen.03.steplen [JOINT_3]STEPLEN

setp [HMOT](CARD0).stepgen.03.stepspace [JOINT_3]STEPSPACE

setp [HMOT](CARD0).stepgen.03.position-scale [JOINT_3]STEP_SCALE

setp [HMOT](CARD0).stepgen.03.step_type 0

setp [HMOT](CARD0).stepgen.03.control-type 1

setp [HMOT](CARD0).stepgen.03.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.03.maxvel [JOINT_3]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net v-pos-cmd <= joint.3.motor-pos-cmd

net v-vel-cmd <= joint.3.vel-cmd

net v-output => [HMOT](CARD0).stepgen.03.velocity-cmd

net v-pos-fb <= [HMOT](CARD0).stepgen.03.position-fb

net v-pos-fb => joint.3.motor-pos-fb

net v-enable <= joint.3.amp-enable-out

net v-enable => [HMOT](CARD0).stepgen.03.enable

# ---setup home / limit switch signals---

#net v-home-sw => joint.3.home-sw-in

net home-v => joint.3.home-sw-in

net v-neg-limit => joint.3.neg-lim-sw-in

net v-pos-limit => joint.3.pos-lim-sw-in

#*******************

# AXIS A JOINT 4

#*******************

setp pid.a.Pgain [JOINT_4]P

setp pid.a.Igain [JOINT_4]I

setp pid.a.Dgain [JOINT_4]D

setp pid.a.bias [JOINT_4]BIAS

setp pid.a.FF0 [JOINT_4]FF0

setp pid.a.FF1 [JOINT_4]FF1

setp pid.a.FF2 [JOINT_4]FF2

setp pid.a.deadband [JOINT_4]DEADBAND

setp pid.a.maxoutput [JOINT_4]MAX_OUTPUT

setp pid.a.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.a.maxerror 0.012700

net a-index-enable => pid.a.index-enable

net a-enable => pid.a.enable

net a-pos-cmd => pid.a.command

net a-pos-fb => pid.a.feedback

net a-output <= pid.a.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.04.dirsetup [JOINT_4]DIRSETUP

setp [HMOT](CARD0).stepgen.04.dirhold [JOINT_4]DIRHOLD

setp [HMOT](CARD0).stepgen.04.steplen [JOINT_4]STEPLEN

setp [HMOT](CARD0).stepgen.04.stepspace [JOINT_4]STEPSPACE

setp [HMOT](CARD0).stepgen.04.position-scale [JOINT_4]STEP_SCALE

setp [HMOT](CARD0).stepgen.04.step_type 0

setp [HMOT](CARD0).stepgen.04.control-type 1

setp [HMOT](CARD0).stepgen.04.maxaccel [JOINT_4]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.04.maxvel [JOINT_4]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net a-pos-cmd <= joint.4.motor-pos-cmd

net a-vel-cmd <= joint.4.vel-cmd

net a-output => [HMOT](CARD0).stepgen.04.velocity-cmd

net a-pos-fb <= [HMOT](CARD0).stepgen.04.position-fb

net a-pos-fb => joint.4.motor-pos-fb

net a-enable <= joint.4.amp-enable-out

net a-enable => [HMOT](CARD0).stepgen.04.enable

# ---setup home / limit switch signals---

net a-home-sw => joint.4.home-sw-in

#net home-a => joint.4.home-sw-in

net a-neg-limit => joint.4.neg-lim-sw-in

net a-pos-limit => joint.4.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

#net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

#net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

#

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

#

net axis-select-u halui.axis.u.select

net jog-u-pos halui.axis.u.plus

net jog-u-neg halui.axis.u.minus

net jog-u-analog halui.axis.u.analog

net u-is-homed halui.joint.2.is-homed

#

net axis-select-v halui.axis.v.select

net jog-v-pos halui.axis.v.plus

net jog-v-neg halui.axis.v.minus

net jog-v-analog halui.axis.v.analog

net v-is-homed halui.joint.3.is-homed

#

net axis-select-a halui.axis.a.select

net jog-a-pos halui.axis.a.plus

net jog-a-neg halui.axis.a.minus

net jog-a-analog halui.axis.a.analog

net a-is-homed halui.joint.4.is-homed

#

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---Use external manual tool change dialog---

loadusr -W hal_manualtoolchange

net tool-change-request => hal_manualtoolchange.change

net tool-change-confirmed <= hal_manualtoolchange.changed

net tool-number => hal_manualtoolchange.number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

the INI file

[code]# Generated by PNCconf at Wed Jul 17 17:05:42 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = foam_cutter

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

FOAM = 1

XY_Z_POS = 5

UV_W_POS = 0

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc002/linuxcnc/nc_files

PYVCP = pyvcp-panel.xml

INCREMENTS = 10mm 1mm .1mm .01mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 25.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

#GEOMETRY = xyz

GEOMETRY = xyuv

CYCLE_TIME = 100

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7i96.0

[HAL]

HALUI = halui

HALFILE = foam_cutter.hal

HALFILE = custom.hal

POSTGUI_HALFILE = pyvcp_options.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

#JOINTS = 4

JOINTS = 5

#KINEMATICS = trivkins coordinates=XYZA

#KINEMATICS = trivkins coordinates=XYUV

KINEMATICS = trivkins coordinates=XYUVA

[TRAJ]

#COORDINATES = XYZA

#COORDINATES = XYUV

COORDINATES = XYUVA

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 2.50

MAX_LINEAR_VELOCITY = 25.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

MIN_LIMIT = -0.01

MAX_LIMIT = 550.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 1600.0

MIN_LIMIT = -0.01

MAX_LIMIT = 550.0

HOME_OFFSET = 0.0

#

HOME_SEARCH_VEL = -1.000000

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

#

HOME_SEQUENCE = 0

#HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800.0

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

HOME_OFFSET = 0.0

#

HOME_SEARCH_VEL = -1.000000

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

#

HOME_SEQUENCE = 0

#HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_U]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

MIN_LIMIT = -0.01

MAX_LIMIT = 550.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800.0

MIN_LIMIT = -0.01

MAX_LIMIT = 550.0

HOME_OFFSET = 0.0

#

HOME_SEARCH_VEL = -1.000000

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

#

HOME_SEQUENCE = 0

#HOME_SEQUENCE = 0

#******************************************

#******************************************

[AXIS_V]

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

[JOINT_3]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 800.0

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

HOME_OFFSET = 0.0

#

HOME_SEARCH_VEL = -1.000000

HOME_LATCH_VEL = -0.500000

HOME_FINAL_VEL = 0.000000

HOME_USE_INDEX = NO

#

HOME_SEQUENCE = 0

#HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_A]

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

MIN_LIMIT = -361.0

MAX_LIMIT = 361.0

[JOINT_4]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 1200.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 450.00

STEPGEN_MAXACCEL = 1500.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 4.4444

MIN_LIMIT = -361.0

MAX_LIMIT = 361.0

HOME_OFFSET = 0.0

#

#HOME_SEARCH_VEL = -1.000000

#HOME_LATCH_VEL = -0.500000

#HOME_FINAL_VEL = 0.000000

#HOME_USE_INDEX = NO

#

HOME_SEQUENCE = 1

#HOME_SEQUENCE = 3

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 100

PYVCP hal

[code]# _DO NOT_ include your HAL commands here.

# Put custom HAL commands in custom_postgui.hal

# The commands in this file are run after the GUI loads

# **** Setup of spindle speed display using pyvcp -START ****

net spindle-vel-cmd-rpm-abs => pyvcp.spindle-speed

net spindle-cw => pyvcp.spindle-at-speed-led

# **** Setup of spindle speed display using pyvcp -END ****

PYVCP xml

[code]<?xml version='1.0' encoding='UTF-8'?>

<pyvcp>

<vbox>

<relief>RIDGE</relief>

<bd>6</bd>

<label>

<text>"Wire Power:"</text>

<font>;("Helvetica",20)</font>

</label>

<bar>

<halpin>"spindle-speed"</halpin>

<max_>100</max_>

</bar>

<label>

<text>"Wire ON:"</text>

<font>;("Helvetica",20)</font>

</label>

<hbox>

<label>

<text>" "</text>

<font>;("Helvetica",20)</font>

</label>

<led>

<halpin>"spindle-at-speed-led"</halpin>

<size>30</size>

<on_color>"red"</on_color>

<off_color>"blue"</off_color>

</led>

</hbox>

</vbox>

</pyvcp>- rdtsc

28 Jul 2024 22:06

Replied by rdtsc on topic Pi4b and Pi5 users - What should go in a 2.9.3 image

Pi4b and Pi5 users - What should go in a 2.9.3 image

Category: Installing LinuxCNC

Would an RTAI variant be applicable to the Rpi4? (Not to create more work for you Rod! But it may be more performant, or no?)

- MarkoPolo

- MarkoPolo

28 Jul 2024 21:44

Replied by MarkoPolo on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

Oh, I wrote that I don't use m70/72. I looked through my ngc again and it does indeed have m70 and m72.

Putting m5 at the beginning of the code solves the problem, maybe in qtvcp procedures such a small correction would also be enough..

Putting m5 at the beginning of the code solves the problem, maybe in qtvcp procedures such a small correction would also be enough..

- Muftijaja

- Muftijaja

28 Jul 2024 21:38 - 28 Jul 2024 21:39

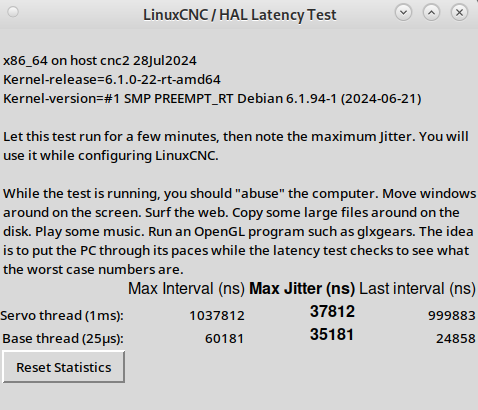

Replied by Muftijaja on topic Latency Test OK, dennoch Fehlermeldung

Latency Test OK, dennoch Fehlermeldung

Category: Deutsch

Thanks for your doc, meanwhile I changed to the internal Intel 82579 network adapter and the jitter grows worse. Do you think the latest Debian and LCNC versions can do better with this combination? I don't have no choice to change to another 2nd adapter, there is no alternative to the Realtec as 2nd network adapter for this computer afaik.

- Grotius

28 Jul 2024 21:33

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

@Lcevette,

In previous post somewhere:

the travelheight has to be at least the G64 P..

in this example the lift height is set at 0.005" which would mean if a P value is set at 0.004"

Then you could use : lift height 0.005 and P0.005. Then it will not go down the z.

Thanks for the gcode file. It loads, but i have some spline problems i see. Haha. I see a lot of spagetti.

So i have to look what's going on and fix it. When it's fixed i will let you know about the file fillets and how they behave.

I had solved a weird thing in the gcode parser.

To convert a string to a double value, some times this failed on other linux pc. It had to do with value using . or , as decimal seperator

as input for the std::stod function.

It's solved by adding : std::locale::global(std::locale("C"));

Thanks, let me know if you need anything else!

A bit off luck... Haha.

Today i coded some more for the look ahead.

I think based on previous post, where the red line of the graph is the velocity profile based on curvature of segments.

This then can be used to retrieve the vo,vm,ve for the trajectory planner.

Arciera mentioned earlyer, the clothoid fillets are quite small, so let we use a vo,vm,ve for each segment.

In previous post somewhere:

the travelheight has to be at least the G64 P..

in this example the lift height is set at 0.005" which would mean if a P value is set at 0.004"

Then you could use : lift height 0.005 and P0.005. Then it will not go down the z.

Thanks for the gcode file. It loads, but i have some spline problems i see. Haha. I see a lot of spagetti.

So i have to look what's going on and fix it. When it's fixed i will let you know about the file fillets and how they behave.

I had solved a weird thing in the gcode parser.

To convert a string to a double value, some times this failed on other linux pc. It had to do with value using . or , as decimal seperator

as input for the std::stod function.

It's solved by adding : std::locale::global(std::locale("C"));

Thanks, let me know if you need anything else!

A bit off luck... Haha.

Today i coded some more for the look ahead.

I think based on previous post, where the red line of the graph is the velocity profile based on curvature of segments.

This then can be used to retrieve the vo,vm,ve for the trajectory planner.

Arciera mentioned earlyer, the clothoid fillets are quite small, so let we use a vo,vm,ve for each segment.

- ississ

28 Jul 2024 21:09

Raspi connect is something I would not use because of the need for cloud connection.

I advice using only services using local network for machine control.

Replied by ississ on topic I want to create a VNC in linuxcnc running in raspberry pi 5

I want to create a VNC in linuxcnc running in raspberry pi 5

Category: General LinuxCNC Questions

One drawback for a terminal is that probably you are not be able to connect to a running process (in this case linuxcnc) but you have to start it inside the terminal. For us that have configuration to start linuxcnc automatically on boot this won't work.If your problem is to only view LinuxCNC on Windows and you are not interested in the desktop of the Linux machine I recommend using an X-Terminal like MobaXterm

mobaxterm.mobatek.net/

Alternatively you can see how this new feature works

www.raspberrypi.com/documentation/services/connect.html

Raspi connect is something I would not use because of the need for cloud connection.

I advice using only services using local network for machine control.

- cmorley

- cmorley

28 Jul 2024 21:07

Replied by cmorley on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

Yes spindle stop button doesn't use m5 it calls spindle off command.

Either way should call the spindle off command.

It will be something in the code that assumes that S 0 = spindle stop, which is not true anymore.

M70/M72 had something similar happen in the right situation.

IIRC it had something to do with using MDI to turn on the spindle and the stop button to turn it off then the M72 would turn it back on because it never got the M5 command.

It should be checking if the spindle is on/off rather then the Gcode M3/4/5.

Your situation sounds the same. I just don't remember if we worked around it or not.

Chris

Either way should call the spindle off command.

It will be something in the code that assumes that S 0 = spindle stop, which is not true anymore.

M70/M72 had something similar happen in the right situation.

IIRC it had something to do with using MDI to turn on the spindle and the stop button to turn it off then the M72 would turn it back on because it never got the M5 command.

It should be checking if the spindle is on/off rather then the Gcode M3/4/5.

Your situation sounds the same. I just don't remember if we worked around it or not.

Chris

- geostein8888

- geostein8888

28 Jul 2024 21:06

Replied by geostein8888 on topic Keyboard gets unresponsive from time to time

Keyboard gets unresponsive from time to time

Category: General LinuxCNC Questions

Hello,

parallel to the linuxcnc i use also windows on the same machine in conjunction with Estlcam and the Estlcam Board (i have still many Estlcam projects i use), here i do not see any problem with the Keyboard

parallel to the linuxcnc i use also windows on the same machine in conjunction with Estlcam and the Estlcam Board (i have still many Estlcam projects i use), here i do not see any problem with the Keyboard

- cmorley

- cmorley

28 Jul 2024 20:56

Replied by cmorley on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

Qtvcp's probe routines use m70 /m72- I do think that is the source of the problem.

- oneohm

28 Jul 2024 20:16

Replied by oneohm on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Thanks for tackling the NVMPG display issue!

I've updated to 3.1.3 and the NVMPG display is now updating correctly.

I have encountered a possible bug:

While jogging with the NVMPG It sometimes changes the axis suddenly and overruns the NVMPG display value, leaving a digit to the extreme left in the X and Y position fields, partially outside the field.

The NVMPG continues to work, but on the new axis and the extra digits remain until power cycled.

Attached is an example of the corrupted display.

I've updated to 3.1.3 and the NVMPG display is now updating correctly.

I have encountered a possible bug:

While jogging with the NVMPG It sometimes changes the axis suddenly and overruns the NVMPG display value, leaving a digit to the extreme left in the X and Y position fields, partially outside the field.

The NVMPG continues to work, but on the new axis and the extra digits remain until power cycled.

Attached is an example of the corrupted display.

- Aciera

28 Jul 2024 20:02

Replied by Aciera on topic After updating to 2.9.3

After updating to 2.9.3

Category: Installing LinuxCNC

Seems that those can be ignored:

forum.linuxcnc.org/49-basic-configuratio...-error-in-log#306221

forum.linuxcnc.org/49-basic-configuratio...-error-in-log#306221

- rdtsc

28 Jul 2024 19:57 - 28 Jul 2024 20:07

Replied by rdtsc on topic iMachI3 P2-S Pendant Install Fail

iMachI3 P2-S Pendant Install Fail

Category: General LinuxCNC Questions

This list is once again incomplete and will likely change again in the future. Instead of posting more changes, check your errors against the following link for the correct names:

linuxcnc.org/docs/html/man/man1/halui.1.html#PINS

linuxcnc.org/docs/html/man/man1/halui.1.html#PINS

Time to create page: 0.844 seconds