Search Results (Searched for: )

- gardenweazel

08 Jul 2024 21:29

- PCW

08 Jul 2024 21:19

Replied by PCW on topic BLDC component with 8i20 - how to get to work?

BLDC component with 8i20 - how to get to work?

Category: Driver Boards

- redeye_joe

08 Jul 2024 21:04

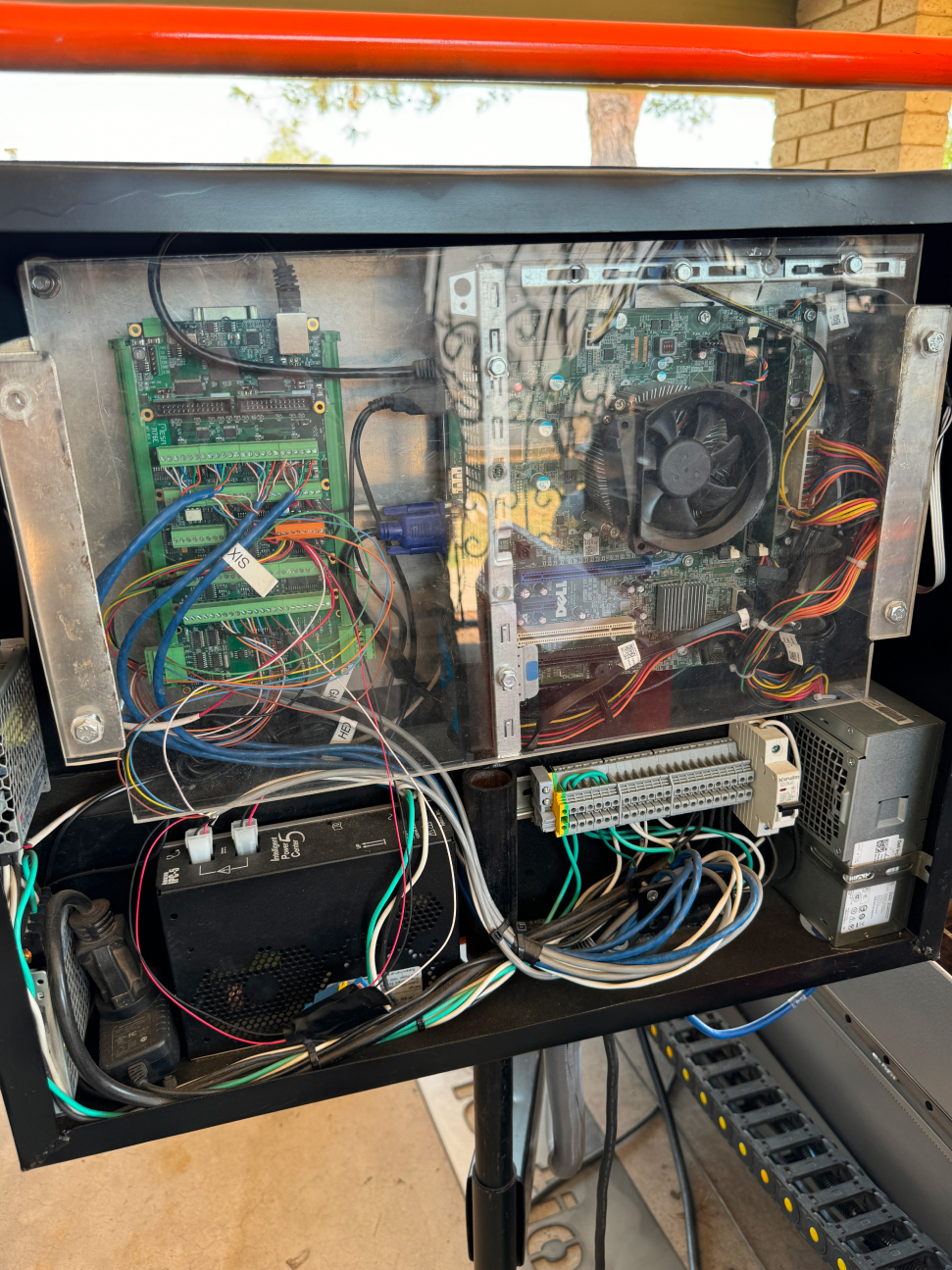

Replied by redeye_joe on topic use a older snapon plasma50 for DIY CNC

use a older snapon plasma50 for DIY CNC

Category: Plasmac

- HerrNamenlos123

08 Jul 2024 20:50

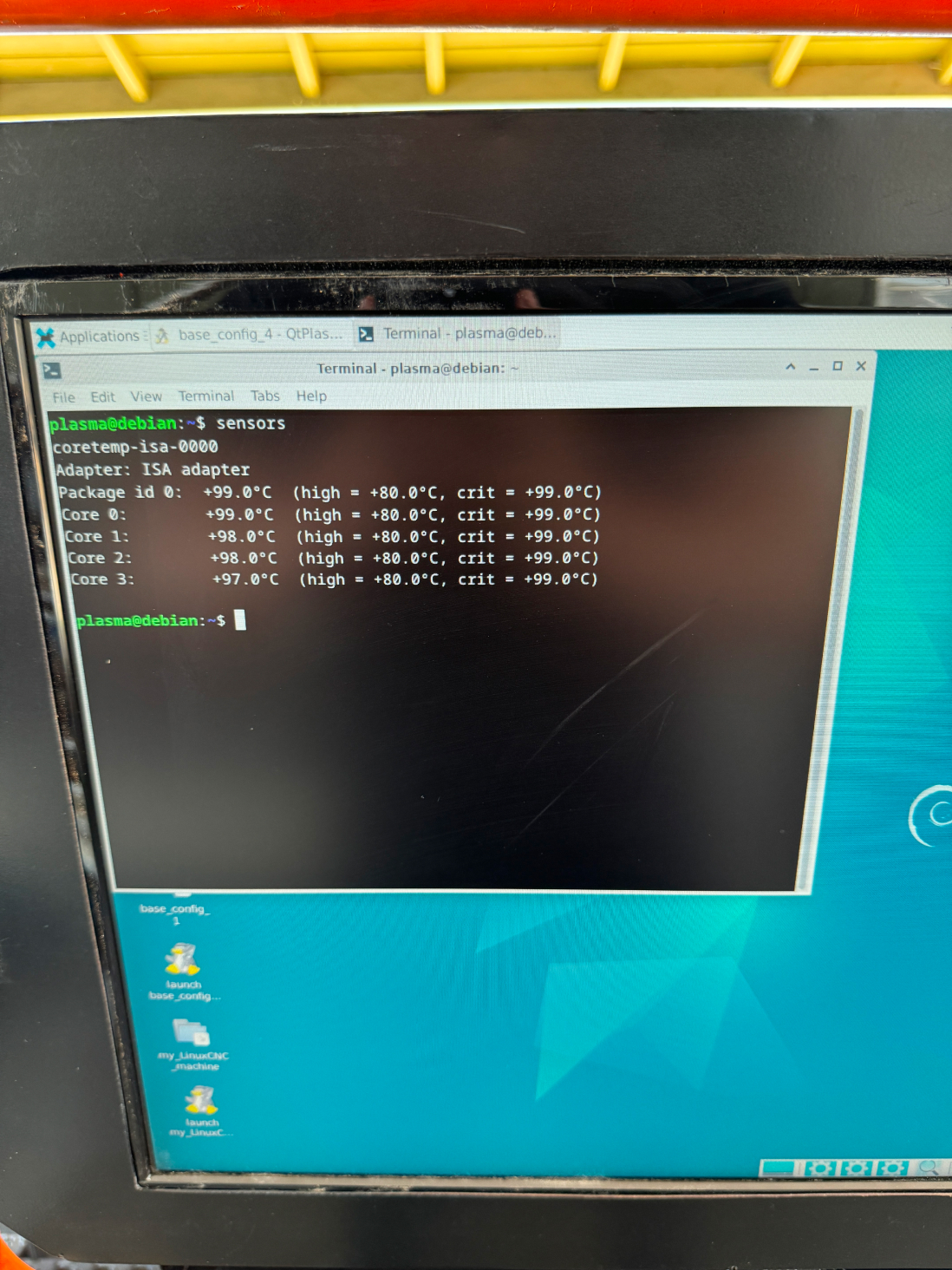

Replied by HerrNamenlos123 on topic How to diagnose crashing LinuxCNC

How to diagnose crashing LinuxCNC

Category: Installing LinuxCNC

- viesturs.lacis

- viesturs.lacis

08 Jul 2024 20:41 - 08 Jul 2024 20:41

Replied by viesturs.lacis on topic BLDC component with 8i20 - how to get to work?

BLDC component with 8i20 - how to get to work?

Category: Driver Boards

- Grotius

08 Jul 2024 20:36

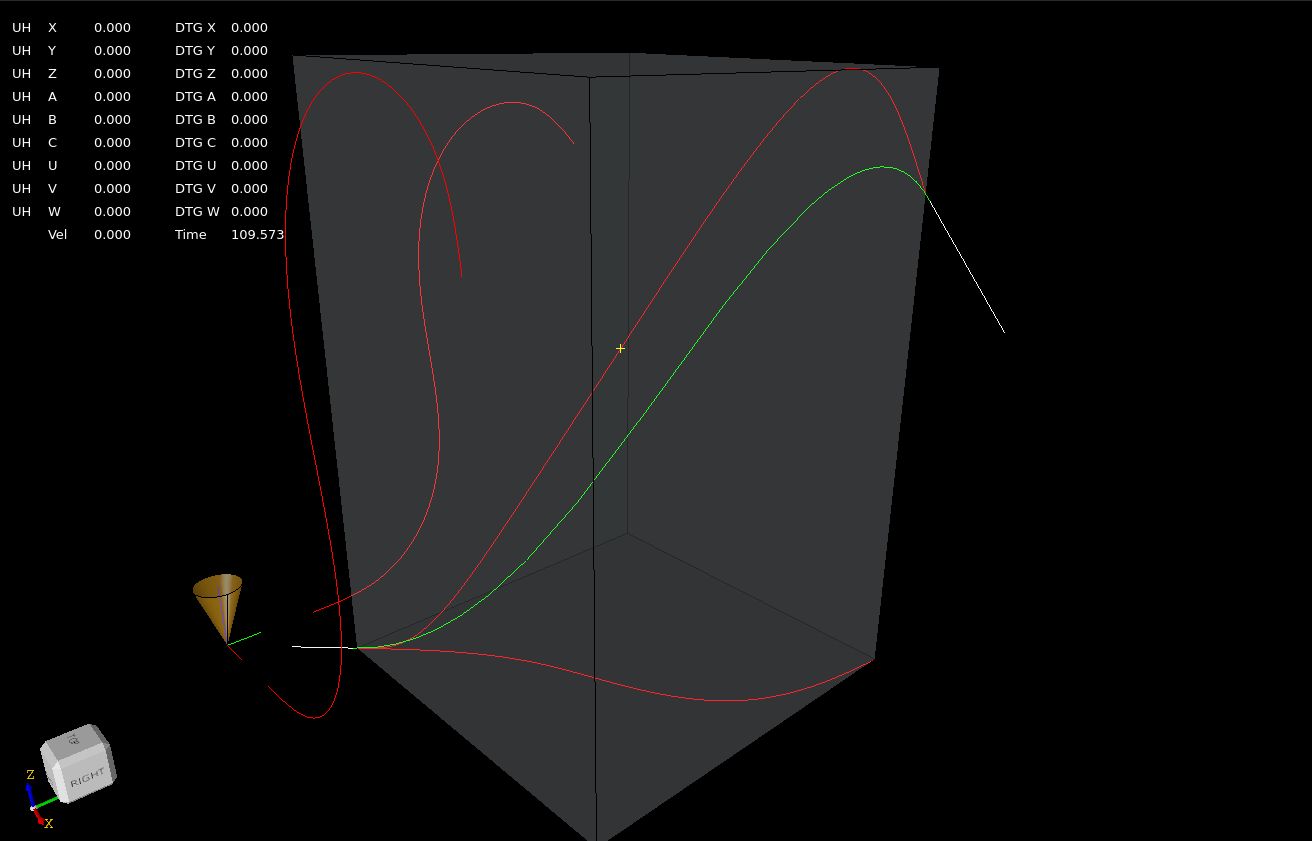

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Grotius

08 Jul 2024 20:35

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- RMJ fabrication

- RMJ fabrication

08 Jul 2024 20:32

Replied by RMJ fabrication on topic qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

qtplasmac (Operation Error: hm2/hm2_7i76e.0:) in middle of cut

Category: Plasmac

- Grotius

08 Jul 2024 20:18

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- rodw

08 Jul 2024 20:17

Replied by rodw on topic Override set_default_blending

Override set_default_blending

Category: Plasmac

- andypugh

08 Jul 2024 20:13

Replied by andypugh on topic Data transfer LinuxCNC to / from custom board - Solved

Data transfer LinuxCNC to / from custom board - Solved

Category: Advanced Configuration

- meister

- meister

08 Jul 2024 20:05

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Cant do this anymore bye all

08 Jul 2024 20:03

Replied by Cant do this anymore bye all on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- HerrNamenlos123

08 Jul 2024 19:46 - 08 Jul 2024 19:51

How to diagnose crashing LinuxCNC was created by HerrNamenlos123

How to diagnose crashing LinuxCNC

Category: Installing LinuxCNC

- ffffrf

- ffffrf

08 Jul 2024 19:32 - 08 Jul 2024 19:35

Replied by ffffrf on topic Controlling mains 0-9v sherline lathe spindle mesa 7i96s

Controlling mains 0-9v sherline lathe spindle mesa 7i96s

Category: Turning

Time to create page: 0.766 seconds