Using user defined parameters:

Result: running as user: mill,

runtime: 7200 seconds,

parameters: --nobase, --base 100000,

prefix for outfiles 1716355190

nglx: 5,

LinuxCNC pc tests, version 20200930, started 22.05.2024 01:21:08

********************************************************************************

Hardware info is logged here: 1716355190.hw.

Latency data is logged here: 1716355190.lat.

General info:

Dell Inc., Vostro 270

Bios version A08, dated 11/23/2012

Chipset: Intel Corporation 7 Series/C216

Harddisk is rotational

The amount of swap currently used is 0

================================================================================

CPU related data:

model name : Intel(R) Core(TM) i5-3570 CPU @ 3.40GHz

cpu cores : 4

stepping : 9

cache size : 6144 KB

================================================================================

RAM related data:

Maximum Capacity: 8 GB

Size: 8 GB

Size: 8 GB

================================================================================

GPU related data:

product: Oland GL [FirePro W2100]

product: Xeon E3-1200 v2/3rd Gen Core processor Graphics Controller

configuration: depth=32 driver=radeon latency=0 resolution=1920,1080

configuration: driver=i915 latency=0

================================================================================

Parallel port related data:

number of parallel ports is 0

================================================================================

Os and desktop related data:

PRETTY_NAME="Debian GNU/Linux 12 (bookworm)"

Should the info below not match with your machine,

kindly post the output of pstree here, including a brief

desciption of your desktop environment, window manager and

display manager. Tia

forum.linuxcnc.org/18-computer/39370-scr...-of-computer-latency

Desktop environment : lightdm

Windowmanager : Xfwm4

Displaymanager : lightdm

================================================================================

Kernel related data:

Kernel 6.1.0-18-rt-amd64

GRUB_CMDLINE_LINUX_DEFAULT="quiet"

Cpu idle driver: intel_idle

================================================================================

Kernel modules data:

Check if pcspkr is loaded: ./lcnc-hw: line 576: [: too many arguments

Yes, may cause bigger latency.

can be eliminated using:

sudo echo "install pcspkr /bin/true" >/etc/modprobe.d/pcspkr.conf

Check if snd modules are loaded: Yes, may cause bigger latency.

can probably be disabled in bios, alternatively, you can run

"./block-snd-modules"

which has just now been created for your convenience.

================================================================================

Keyboard & Mouse related data:

Number of mice: 1

Mouse 0 : Telink Wireless Receiver Mouse

Mice attached to USB:

./lcnc-hw: line 631: lsusb: command not found

Keyboards attached to USB:

./lcnc-hw: line 633: lsusb: command not found

================================================================================

LinuxCNC related data:

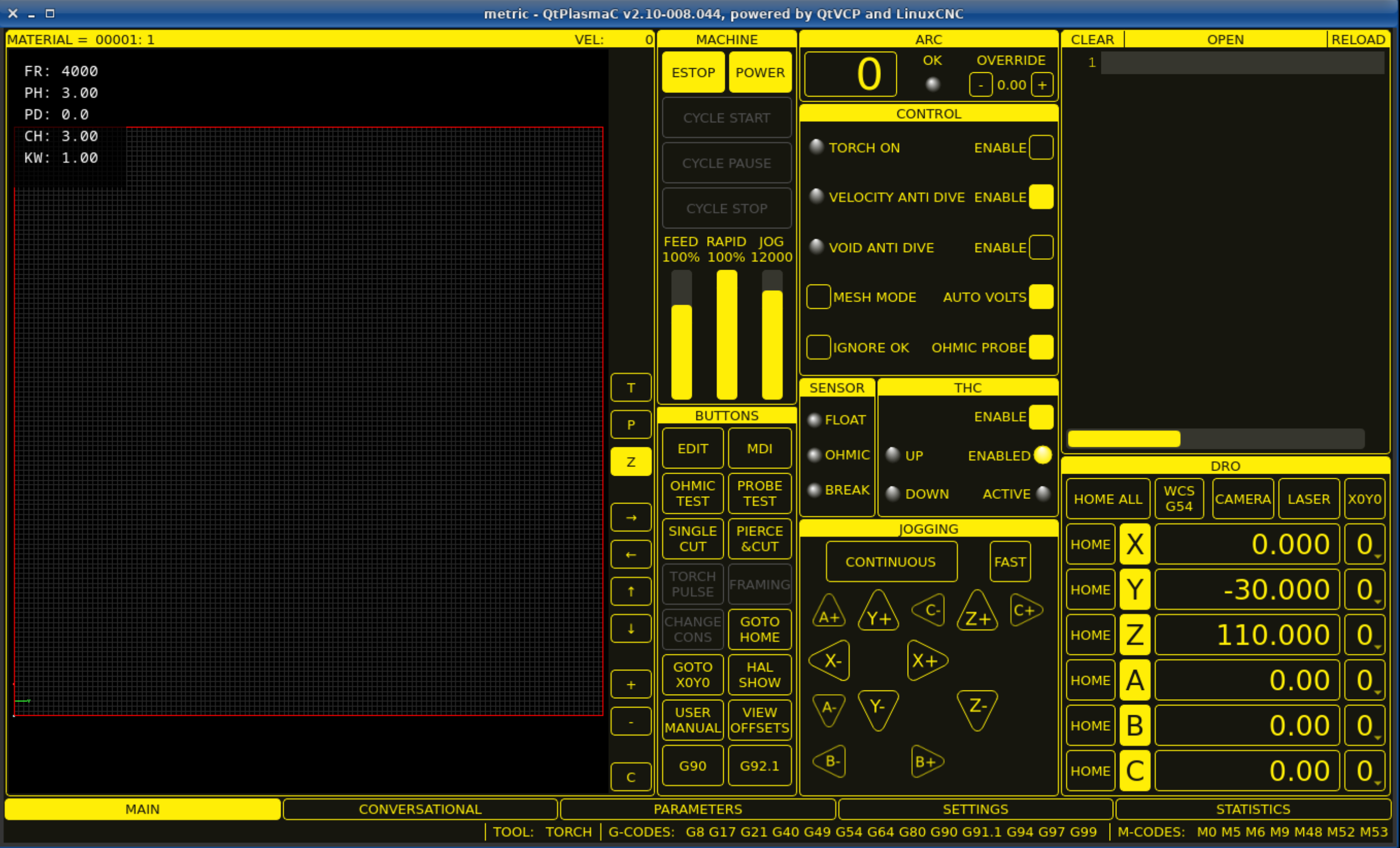

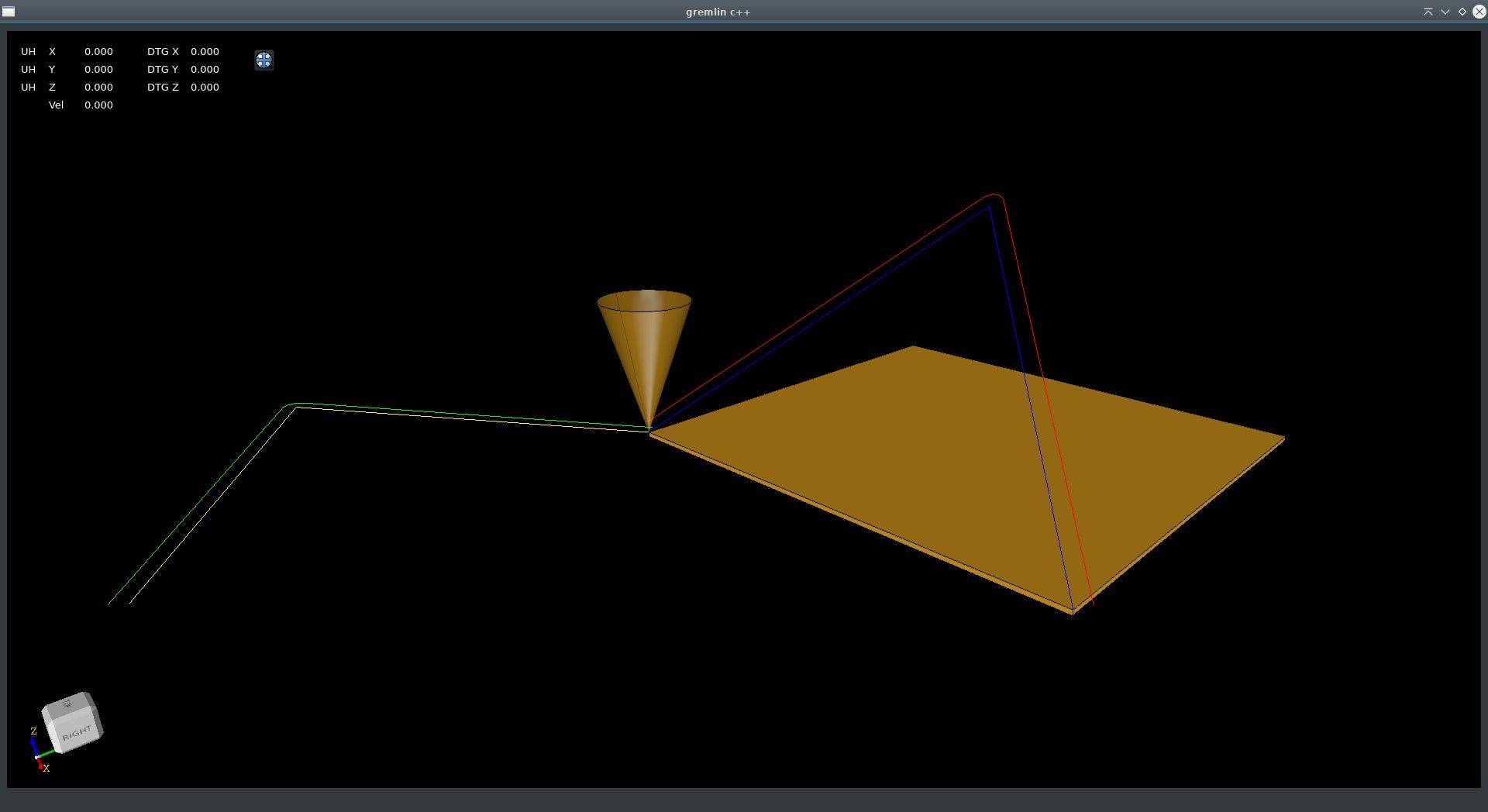

LinuxCNC version is: 2.9.2

================================================================================

Preparing for latency test:

Started glxgears No. 1, 2, 3, 4, 5

......ATTENTION: default value of option mesa_glthread overridden by environment.

ATTENTION: default value of option mesa_glthread overridden by environment.

ATTENTION: default value of option mesa_glthread overridden by environment.

....

Started firefox with '

vimeo.com/150574260', WID

================================================================================

STartime = Wed May 22 01:21:22 AM EDT 2024

Command for latency test is:

su mill -c "latency-histogram --nobase --base 100000 --sbinsize 1000 --nox 2>&1 | tee -a 1716355190.lat &"

Latency testing loop started Wed May 22 01:21:22 AM EDT 2024,

should end after Wed May 22 03:21:22 AM EDT 2024

Core 0: +49.0°C (high = +85.0°C, crit = +105.0°C)

Core 1: +48.0°C (high = +85.0°C, crit = +105.0°C)

Core 2: +46.0°C (high = +85.0°C, crit = +105.0°C)

Core 3: +46.0°C (high = +85.0°C, crit = +105.0°C)

done command, retval = 0

.Note: Using POSIX realtime

0 s servo min: -4.400 us max: 5.400 us sdev: 1.600 us

. 1 s servo min: -4.400 us max: 7.100 us sdev: 1.600 us

2 s servo min: -5.500 us max: 7.600 us sdev: 1.600 us

. 2 s servo min: -7.700 us max: 10.100 us sdev: 1.700 us

. 3 s servo min: -7.700 us max: 10.100 us sdev: 1.700 us

4 s servo min: -7.700 us max: 10.100 us sdev: 1.600 us

. 4 s servo min: -7.700 us max: 10.100 us sdev: 1.600 us

5 s servo min: -7.700 us max: 10.100 us sdev: 1.700 us

There are no windows in the stack

Invalid window '%1'

Usage: windowactivate [options] [window=%1]

--sync - only exit once the window is active (is visible + active)

If no window is given, %1 is used. See WINDOW STACK in xdotool(1)

Remaining 0d 1h:59m:55s, press ^C to abort...

6 s servo min: -15.200 us max: 13.200 us sdev: 1.700 us

6 s servo min: -15.200 us max: 13.200 us sdev: 1.700 us

7 s servo min: -15.200 us max: 13.200 us sdev: 1.700 us

7 s servo min: -15.200 us max: 13.200 us sdev: 1.700 us

8 s servo min: -15.200 us max: 13.200 us sdev: 1.700 us

9 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

9 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

Core 0: +57.0°C (high = +85.0°C, crit = +105.0°C)

Core 1: +57.0°C (high = +85.0°C, crit = +105.0°C)

Core 2: +54.0°C (high = +85.0°C, crit = +105.0°C)

Core 3: +53.0°C (high = +85.0°C, crit = +105.0°C)

Remaining 0d 1h:59m:50s, press ^C to abort...

10 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

11 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

11 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

12 s servo min: -23.900 us max: 24.300 us sdev: 1.800 us

13 s servo min: -23.900 us max: 24.300 us sdev: 1.700 us

13 s servo min: -23.900 us max: 24.300 us sdev: 1.700 us

14 s servo min: -23.900 us max: 24.300 us sdev: 1.700 us

15 s servo min: -23.900 us max: 24.300 us sdev: 1.700 us

Core 0: +59.0°C (high = +85.0°C, crit = +105.0°C)

Core 1: +58.0°C (high = +85.0°C, crit = +105.0°C)

Core 2: +56.0°C (high = +85.0°C, crit = +105.0°C)

Core 3: +54.0°C (high = +85.0°C, crit = +105.0°C)

Remaining 0d 1h:59m:45s, press ^C to abort...

15 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

16 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

17 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

17 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

18 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

19 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

19 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

20 s servo min: -49.500 us max: 35.900 us sdev: 1.700 us

Core 0: +61.0°C (high = +85.0°C, crit = +105.0°C)

Core 1: +59.0°C (high = +85.0°C, crit = +105.0°C)

Core 2: +55.0°C (high = +85.0°C, crit = +105.0°C)

Core 3: +56.0°C (high = +85.0°C, crit = +105.0°C)

Remaining 0d 1h:59m:40s, press ^C to abort...