Search Results (Searched for: )

- TangentAudio

- TangentAudio

20 May 2024 16:55

Replied by TangentAudio on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- MarkoPolo

- MarkoPolo

20 May 2024 16:41 - 21 May 2024 11:26

Replied by MarkoPolo on topic Error in tool_offsetview.py

Error in tool_offsetview.py

Category: Qtvcp

- Domsku

20 May 2024 16:22

MB2HAL with VFD and Arduino was created by Domsku

MB2HAL with VFD and Arduino

Category: Advanced Configuration

- andrew2085

- andrew2085

20 May 2024 16:06

Replied by andrew2085 on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- TangentAudio

- TangentAudio

20 May 2024 15:04

Replied by TangentAudio on topic Dual PID loops with motor encoder + scale encoder per axis

Dual PID loops with motor encoder + scale encoder per axis

Category: Advanced Configuration

- Tinine

- Tinine

20 May 2024 14:39

Replied by Tinine on topic Dual PID loops with motor encoder + scale encoder per axis

Dual PID loops with motor encoder + scale encoder per axis

Category: Advanced Configuration

- PCW

20 May 2024 14:24

- TangentAudio

- TangentAudio

20 May 2024 14:23

Replied by TangentAudio on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Ludwig

- Ludwig

20 May 2024 14:18

- stonebite

- stonebite

20 May 2024 14:07 - 20 May 2024 14:13

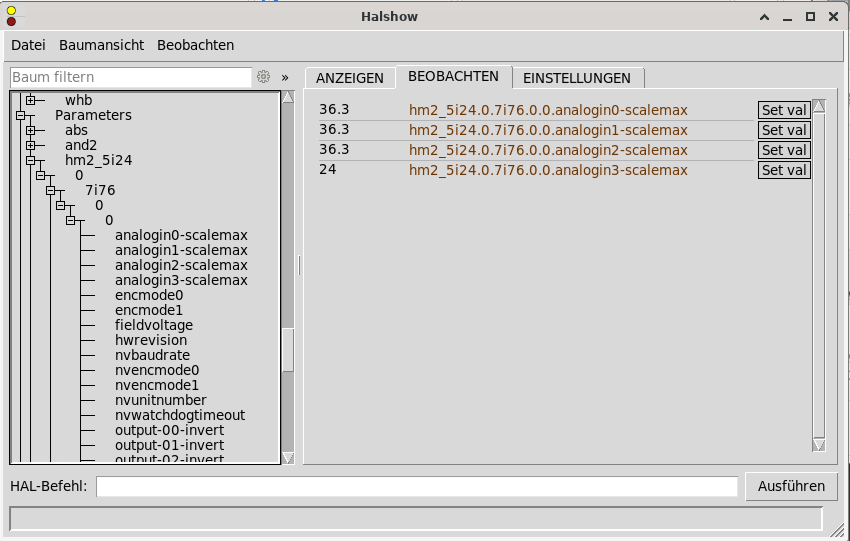

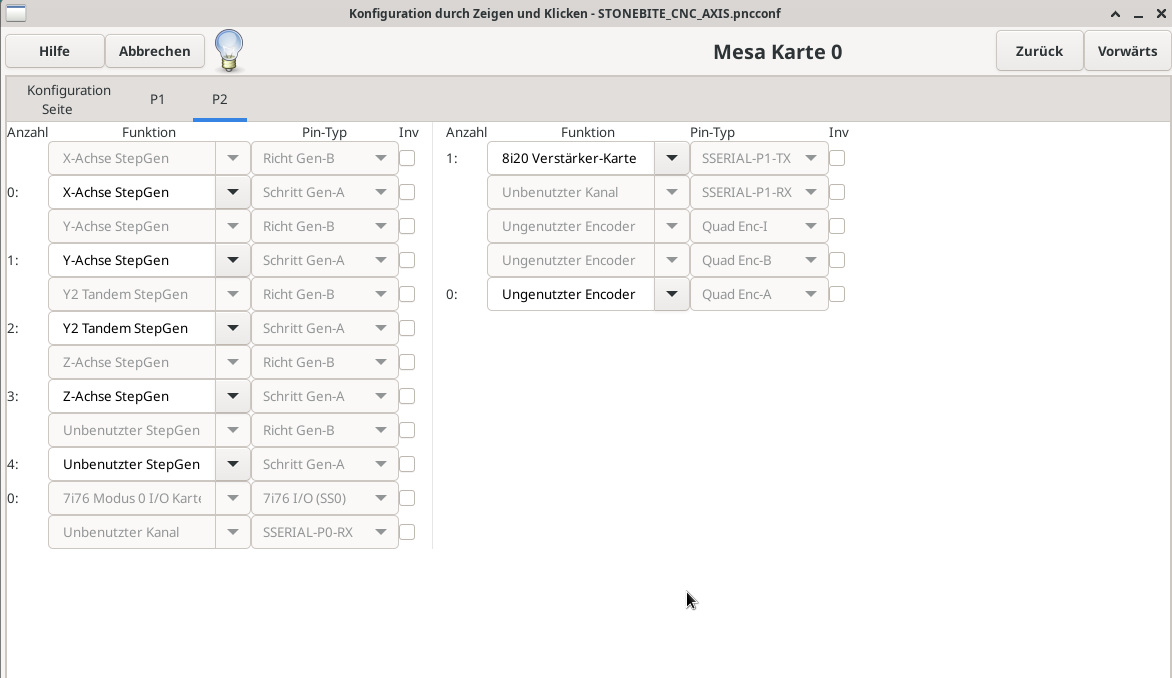

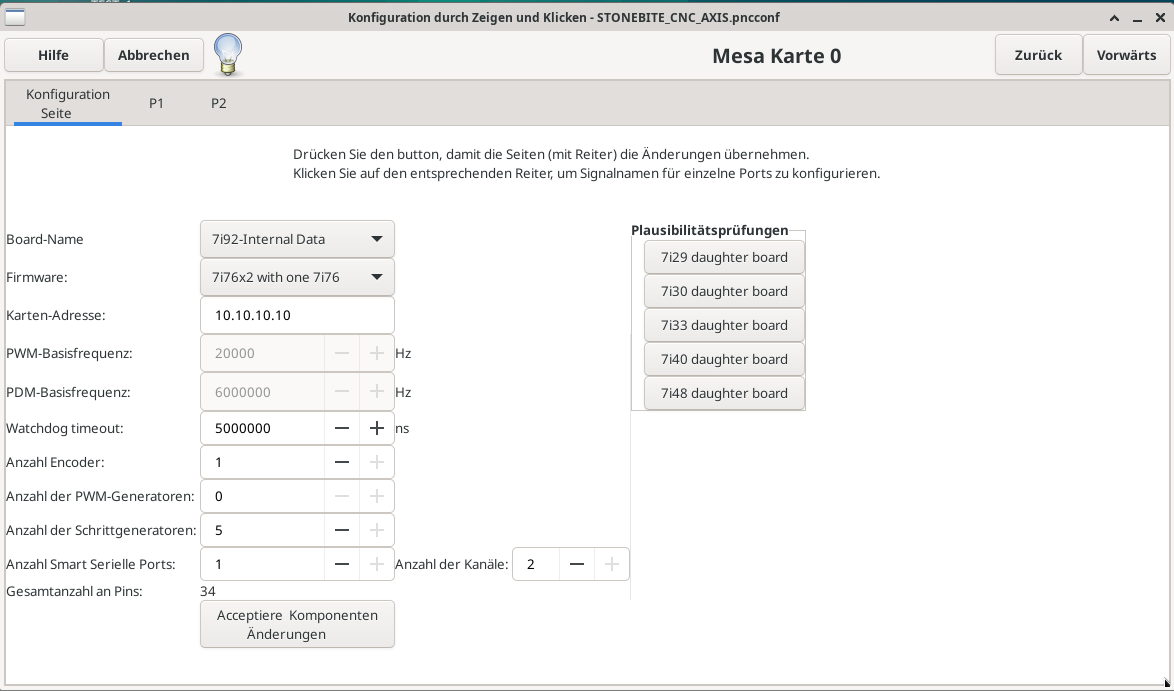

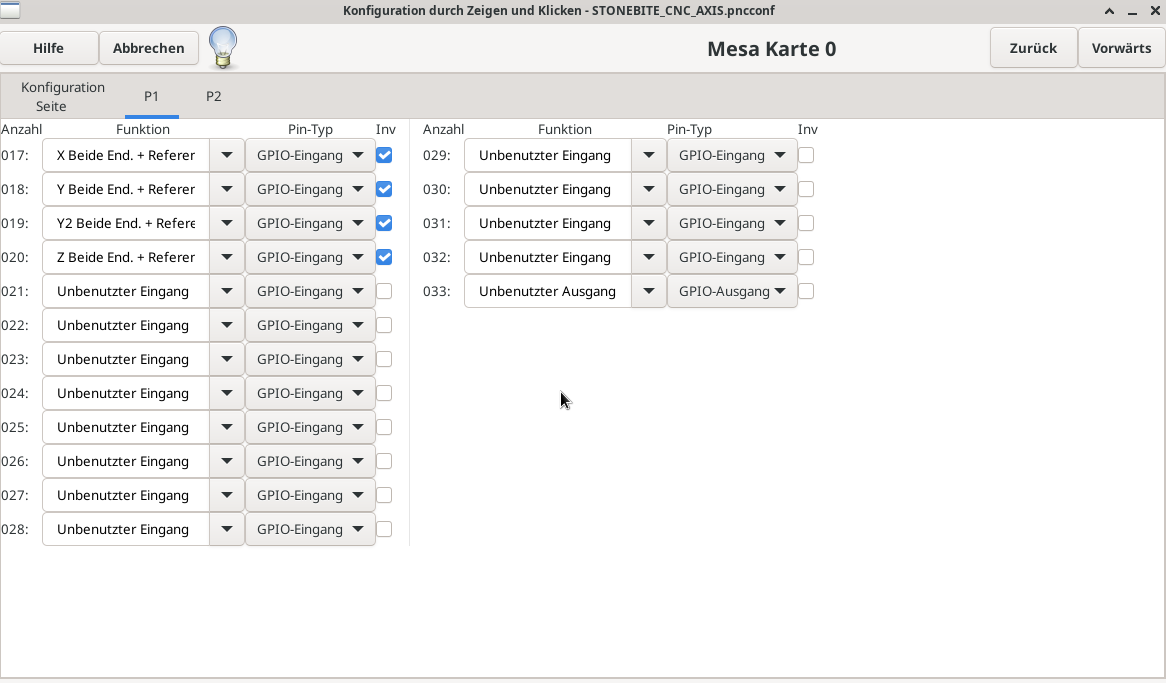

Replied by stonebite on topic PNCconf 7i92H and 7i76

PNCconf 7i92H and 7i76

Category: PnCConf Wizard

- strahlensauger

20 May 2024 13:44

Replied by strahlensauger on topic I can no longer access a Linuxcnc page

I can no longer access a Linuxcnc page

Category: LinuxCNC Documents

- rodw

20 May 2024 13:34

Replied by rodw on topic help with component creation

help with component creation

Category: General LinuxCNC Questions

- rodw

20 May 2024 13:21

Replied by rodw on topic I can no longer access a Linuxcnc page

I can no longer access a Linuxcnc page

Category: LinuxCNC Documents

- Grotius

20 May 2024 13:21

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- PCW

20 May 2024 13:19

Time to create page: 0.530 seconds