Search Results (Searched for: )

- TangentAudio

- TangentAudio

13 May 2024 12:38

Replied by TangentAudio on topic Announcing Deckard: StreamDeck support for LinuxCNC

Announcing Deckard: StreamDeck support for LinuxCNC

Category: Show Your Stuff

- TangentAudio

- TangentAudio

13 May 2024 12:36

Replied by TangentAudio on topic Announcing Deckard: StreamDeck support for LinuxCNC

Announcing Deckard: StreamDeck support for LinuxCNC

Category: Show Your Stuff

- jjdege

13 May 2024 12:24 - 13 May 2024 12:28

Replied by jjdege on topic joint 0 follwing error and driver Er 818

joint 0 follwing error and driver Er 818

Category: EtherCAT

- Unlogic

- Unlogic

13 May 2024 12:01

Replied by Unlogic on topic TOOL_CHANGE_QUILL_UP behaviour

TOOL_CHANGE_QUILL_UP behaviour

Category: General LinuxCNC Questions

- cekaa

13 May 2024 11:54 - 13 May 2024 12:52

Replied by cekaa on topic EtherCAT stopped working after Reboot

EtherCAT stopped working after Reboot

Category: EtherCAT

- Aciera

13 May 2024 11:49

Replied by Aciera on topic Help in setting up LinuxCNC

Help in setting up LinuxCNC

Category: Basic Configuration

- Aciera

13 May 2024 11:37

Replied by Aciera on topic TOOL_CHANGE_QUILL_UP behaviour

TOOL_CHANGE_QUILL_UP behaviour

Category: General LinuxCNC Questions

- tommylight

13 May 2024 11:28

Replied by tommylight on topic The blacksmith's plasma table

The blacksmith's plasma table

Category: Plasma & Laser

- Abdulkareem

- Abdulkareem

13 May 2024 11:21

joint 0 follwing error and driver Er 818 was created by Abdulkareem

joint 0 follwing error and driver Er 818

Category: EtherCAT

- polskleforgeron

- polskleforgeron

13 May 2024 11:18 - 13 May 2024 11:20

Replied by polskleforgeron on topic The blacksmith's plasma table

The blacksmith's plasma table

Category: Plasma & Laser

- amanker

- amanker

13 May 2024 10:56

Help in setting up LinuxCNC was created by amanker

Help in setting up LinuxCNC

Category: Basic Configuration

- burnie

- burnie

13 May 2024 10:50

Replied by burnie on topic EtherCAT stopped working after Reboot

EtherCAT stopped working after Reboot

Category: EtherCAT

- cekaa

13 May 2024 10:43

Replied by cekaa on topic EtherCAT stopped working after Reboot

EtherCAT stopped working after Reboot

Category: EtherCAT

- Unlogic

- Unlogic

13 May 2024 10:25

TOOL_CHANGE_QUILL_UP behaviour was created by Unlogic

TOOL_CHANGE_QUILL_UP behaviour

Category: General LinuxCNC Questions

- Unlogic

- Unlogic

13 May 2024 09:38 - 13 May 2024 20:28

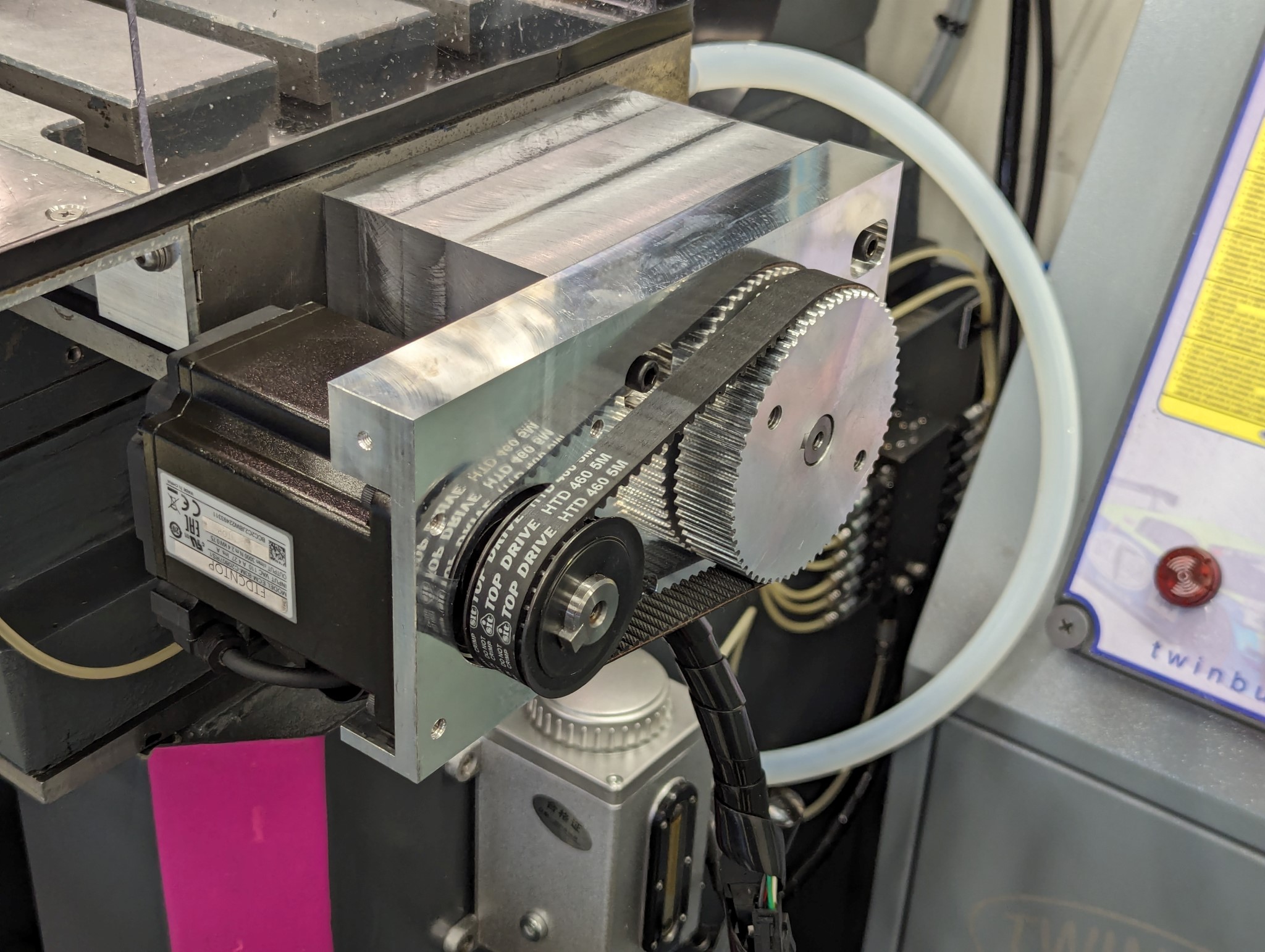

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

Time to create page: 0.654 seconds