Search Results (Searched for: )

- PCW

22 Nov 2025 15:46

Replied by PCW on topic Chinese Mesa 7I92 from aliexpress NEW

Chinese Mesa 7I92 from aliexpress NEW

Category: Driver Boards

- tommylight

22 Nov 2025 14:21

- bszoke

- bszoke

22 Nov 2025 13:43

- aDm1N

22 Nov 2025 13:38 - 22 Nov 2025 20:55

- Aciera

22 Nov 2025 12:50

Replied by Aciera on topic linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

Category: General LinuxCNC Questions

- unknown

- unknown

22 Nov 2025 12:45

- unknown

- unknown

22 Nov 2025 12:43

Replied by unknown on topic linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

Category: General LinuxCNC Questions

- unknown

- unknown

22 Nov 2025 12:31

Replied by unknown on topic Chinese Mesa 7I92 from aliexpress NEW

Chinese Mesa 7I92 from aliexpress NEW

Category: Driver Boards

- unknown

- unknown

22 Nov 2025 12:18

Replied by unknown on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- Muzzer

- Muzzer

22 Nov 2025 11:58

Replied by Muzzer on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- Sekai

- Sekai

22 Nov 2025 11:19 - 22 Nov 2025 11:29

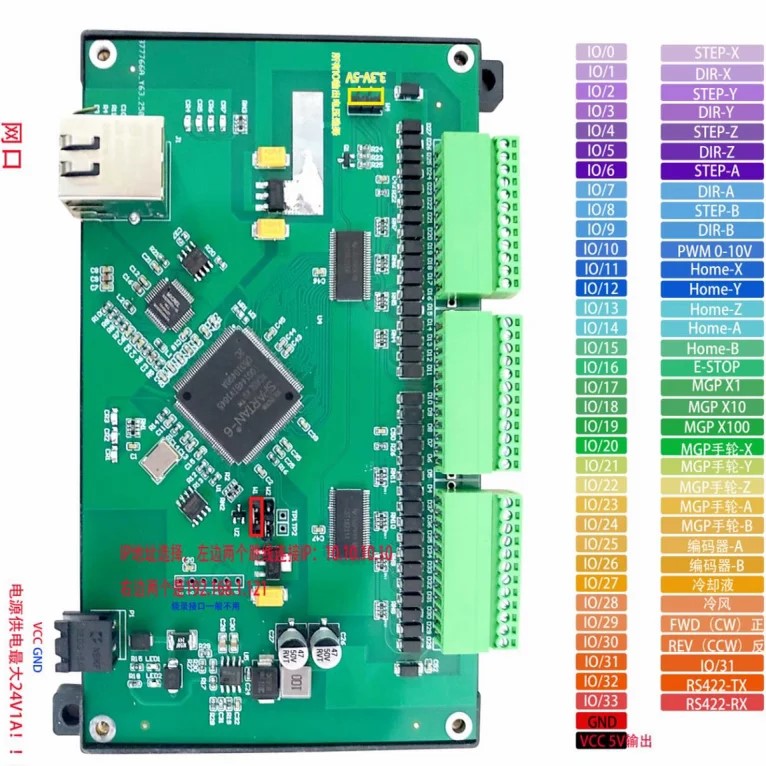

Chinese Mesa 7I92 from aliexpress NEW was created by Sekai

Chinese Mesa 7I92 from aliexpress NEW

Category: Driver Boards

- T.Frei

- T.Frei

22 Nov 2025 10:10

- abs32

- abs32

22 Nov 2025 09:49 - 22 Nov 2025 09:54

Replied by abs32 on topic How to fix "Queue is not empty after probing"

How to fix "Queue is not empty after probing"

Category: General LinuxCNC Questions

- rodw

22 Nov 2025 09:44

Replied by rodw on topic How to fix "Queue is not empty after probing"

How to fix "Queue is not empty after probing"

Category: General LinuxCNC Questions

- Hakan

- Hakan

22 Nov 2025 09:41

Time to create page: 0.433 seconds