Search Results (Searched for: )

- unknown

- unknown

20 Sep 2025 05:55

Replied by unknown on topic Recommendations for a dual NIC SBC or mini-pc

Recommendations for a dual NIC SBC or mini-pc

Category: EtherCAT

- CarbonNater

- CarbonNater

20 Sep 2025 03:12

Replied by CarbonNater on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

ECMO VMC100 Retrofit with Carousel/Toolchanger

Category: Milling Machines

- PCW

20 Sep 2025 01:03

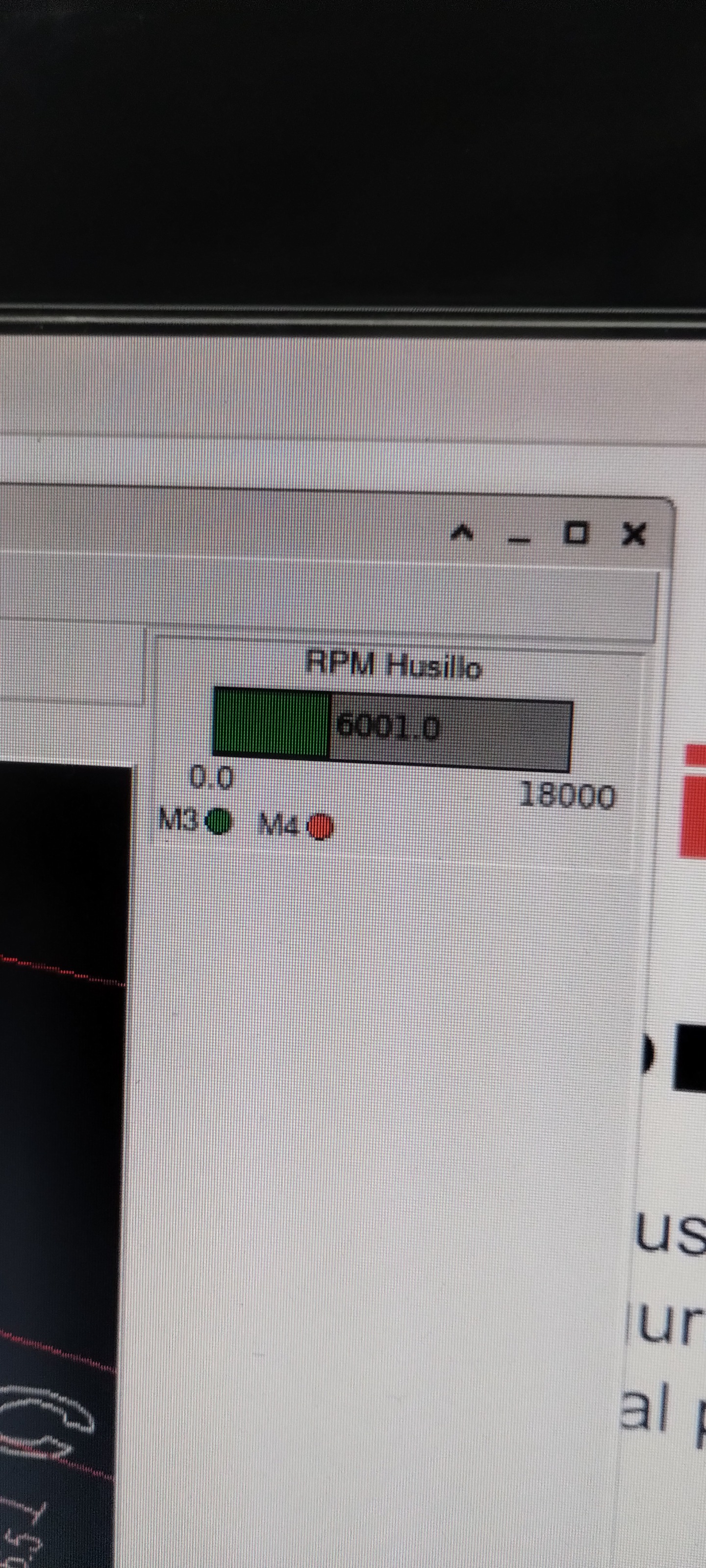

Replied by PCW on topic 7i76E Spindle configuration

7i76E Spindle configuration

Category: PnCConf Wizard

- isaac

20 Sep 2025 00:35

MPG whb04b-6 starts by default in MPG Mode was created by isaac

MPG whb04b-6 starts by default in MPG Mode

Category: HAL

- RobotMatic

20 Sep 2025 00:18

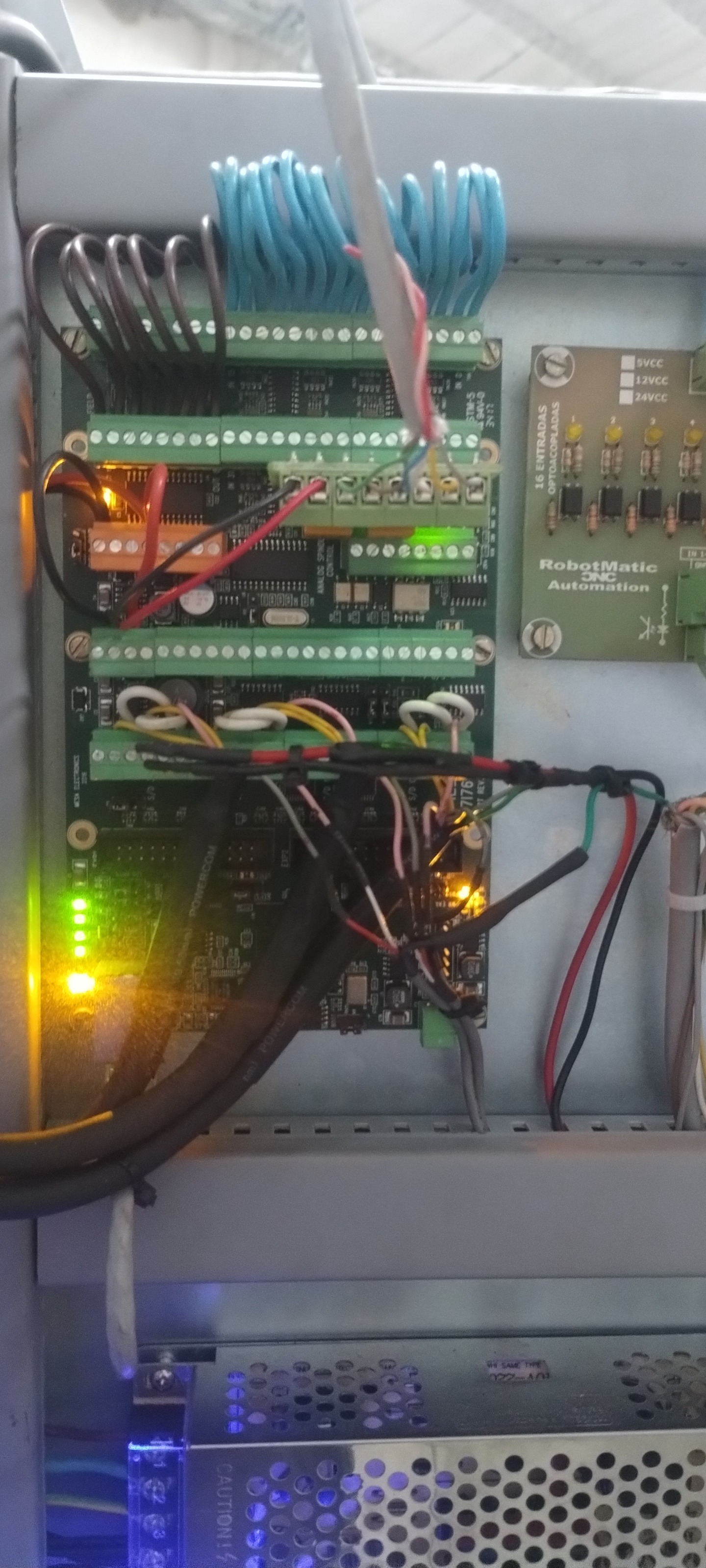

Replied by RobotMatic on topic 7i76E Spindle configuration

7i76E Spindle configuration

Category: PnCConf Wizard

- krille

- krille

19 Sep 2025 21:14

- tommylight

19 Sep 2025 20:30

Replied by tommylight on topic Looking for a freelancer to help me with my project?

Looking for a freelancer to help me with my project?

Category: User Exchange

- PCW

19 Sep 2025 19:18

- scsmith1451

19 Sep 2025 18:50

Linear Move Exceeds Lower Limit was created by scsmith1451

Linear Move Exceeds Lower Limit

Category: General LinuxCNC Questions

- scsmith1451

19 Sep 2025 18:32

- krille

- krille

19 Sep 2025 17:29

- BorisMatris

- BorisMatris

19 Sep 2025 15:37

Looking for a freelancer to help me with my project? was created by BorisMatris

Looking for a freelancer to help me with my project?

Category: User Exchange

- tommylight

19 Sep 2025 13:57

Replied by tommylight on topic Firmware Request for 7i92 – Plasma CNC Build

Firmware Request for 7i92 – Plasma CNC Build

Category: Driver Boards

- souh-hil

19 Sep 2025 13:50

Replied by souh-hil on topic Firmware Request for 7i92 – Plasma CNC Build

Firmware Request for 7i92 – Plasma CNC Build

Category: Driver Boards

- alexandrap

- alexandrap

19 Sep 2025 13:30 - 20 Sep 2025 13:55

Time to create page: 0.347 seconds