Search Results (Searched for: )

- grandixximo

11 Jan 2026 11:44

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- deckname

- deckname

11 Jan 2026 11:30

Replied by deckname on topic QtPlasmaC + CoreXY Kinematics

QtPlasmaC + CoreXY Kinematics

Category: General LinuxCNC Questions

- 3404gerber

- 3404gerber

11 Jan 2026 11:27

Replied by 3404gerber on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- RotarySMP

11 Jan 2026 11:25 - 11 Jan 2026 11:26

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Retrofitting a 1986 Maho MH400E

Category: Milling Machines

- hhscott

- hhscott

11 Jan 2026 10:49

- andrax

- andrax

11 Jan 2026 10:36

- dschultz

- dschultz

11 Jan 2026 01:14

- tommylight

10 Jan 2026 23:43

Replied by tommylight on topic QtPlasmaC + CoreXY Kinematics

QtPlasmaC + CoreXY Kinematics

Category: General LinuxCNC Questions

- deckname

- deckname

10 Jan 2026 23:32

QtPlasmaC + CoreXY Kinematics was created by deckname

QtPlasmaC + CoreXY Kinematics

Category: General LinuxCNC Questions

- tommylight

10 Jan 2026 22:16

Replied by tommylight on topic Failure to find Named Subroutines

Failure to find Named Subroutines

Category: O Codes (subroutines) and NGCGUI

- cnbbom

- cnbbom

10 Jan 2026 22:01 - 10 Jan 2026 22:52

Replied by cnbbom on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- Tomatendose

- Tomatendose

10 Jan 2026 22:01 - 10 Jan 2026 22:13

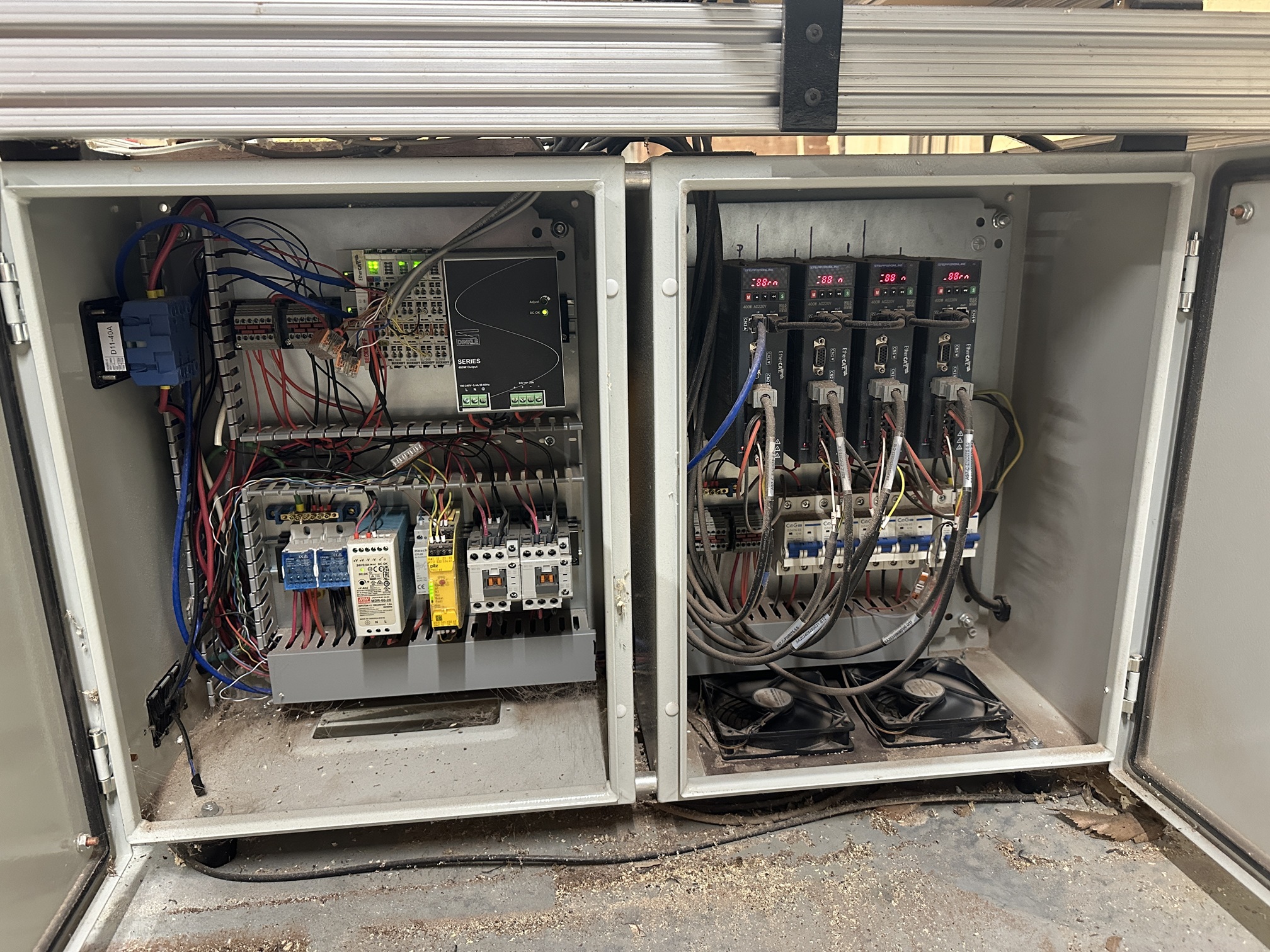

Replied by Tomatendose on topic Commission drive on AX5206) using TC3 to prep for linuxcnc-ethercat

Commission drive on AX5206) using TC3 to prep for linuxcnc-ethercat

Category: EtherCAT

- MaHa

- MaHa

10 Jan 2026 21:57

Replied by MaHa on topic Failure to find Named Subroutines

Failure to find Named Subroutines

Category: O Codes (subroutines) and NGCGUI

- roycegb

- roycegb

10 Jan 2026 21:17

Replied by roycegb on topic Failure to find Named Subroutines

Failure to find Named Subroutines

Category: O Codes (subroutines) and NGCGUI

- freemoore

- freemoore

10 Jan 2026 20:19

Time to create page: 1.221 seconds