Search Results (Searched for: )

- tommylight

22 Mar 2025 12:03

Replied by tommylight on topic Any experience with cnc-step machines?

Any experience with cnc-step machines?

Category: Milling Machines

- tommylight

22 Mar 2025 12:00

Replied by tommylight on topic Mesa 7i95T config for workbench tests - to drive H-Bridges + PMDC servos

Mesa 7i95T config for workbench tests - to drive H-Bridges + PMDC servos

Category: Configuration Tools

- tommylight

22 Mar 2025 11:54

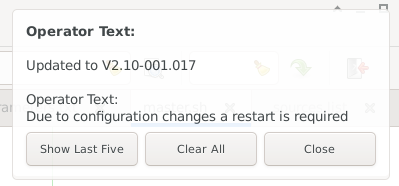

Replied by tommylight on topic QTplasmac Configs do not open after converting to master debs on buildbot2

QTplasmac Configs do not open after converting to master debs on buildbot2

Category: Plasmac

- mehtaraj40

- mehtaraj40

22 Mar 2025 11:49

Implementing S curve was created by mehtaraj40

Implementing S curve

Category: General LinuxCNC Questions

- rodw

22 Mar 2025 11:33

Replied by rodw on topic Config will not open after Buildbot2 upgade from 2.9.4 to 2.10

Config will not open after Buildbot2 upgade from 2.9.4 to 2.10

Category: Plasmac

- d12k6

- d12k6

22 Mar 2025 10:44 - 22 Mar 2025 10:48

- rodw

22 Mar 2025 10:31

- Aciera

22 Mar 2025 09:56

Replied by Aciera on topic Regarding the question of following control on the assembly line

Regarding the question of following control on the assembly line

Category: General LinuxCNC Questions

- Aciera

22 Mar 2025 09:55

Replied by Aciera on topic C Axis as Second Spindle

C Axis as Second Spindle

Category: General LinuxCNC Questions

- mclien

- mclien

22 Mar 2025 09:37 - 22 Mar 2025 09:38

Replied by mclien on topic Any experience with cnc-step machines?

Any experience with cnc-step machines?

Category: Milling Machines

- matasbuk

- matasbuk

22 Mar 2025 09:22

Replied by matasbuk on topic QTDragon_hd won't display a larger file.

QTDragon_hd won't display a larger file.

Category: Qtvcp

- Hakan

- Hakan

22 Mar 2025 09:03

- Hakan

- Hakan

22 Mar 2025 08:09

Replied by Hakan on topic Any experience with cnc-step machines?

Any experience with cnc-step machines?

Category: Milling Machines

- Boogie

- Boogie

22 Mar 2025 07:08

- Boogie

- Boogie

22 Mar 2025 06:38

Replied by Boogie on topic Used Laptops tested with LinuxCNC and Mesa Ethernet boards

Used Laptops tested with LinuxCNC and Mesa Ethernet boards

Category: Computers and Hardware

Time to create page: 0.327 seconds