Search Results (Searched for: )

- scda

16 Mar 2025 15:04 - 16 Mar 2025 15:09

caxis.comp with stepper motor / gear connection to spindle was created by scda

caxis.comp with stepper motor / gear connection to spindle

Category: HAL

- PostavCNC

16 Mar 2025 15:03 - 16 Mar 2025 15:04

Replied by PostavCNC on topic Keyboard Shortcuts in Gmoccapy

Keyboard Shortcuts in Gmoccapy

Category: Gmoccapy

- PCW

16 Mar 2025 15:00

Replied by PCW on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

- PCW

16 Mar 2025 14:34

Replied by PCW on topic STEPLEN STEPSPACE time for Bergerda AC servo driver

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- tsaG

- tsaG

16 Mar 2025 14:21 - 16 Mar 2025 21:21

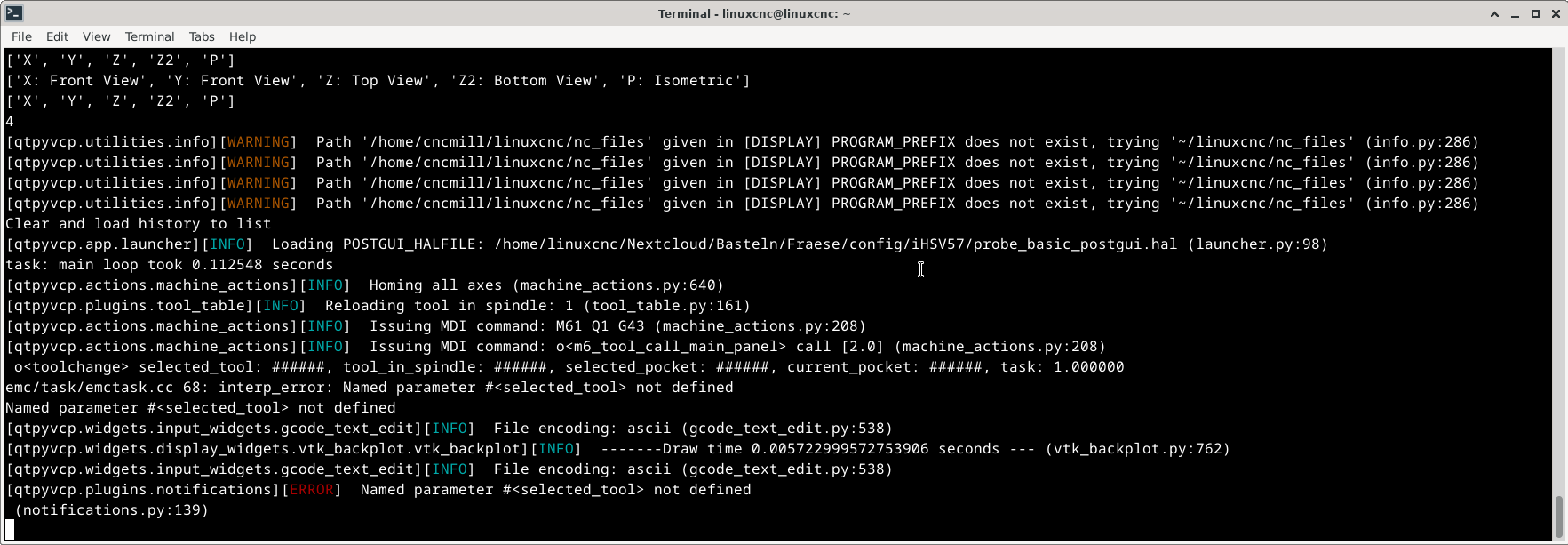

Replied by tsaG on topic No parameters forwarded to M6 script?

No parameters forwarded to M6 script?

Category: QtPyVCP

- papagno-source

- papagno-source

16 Mar 2025 14:12 - 16 Mar 2025 14:28

Replied by papagno-source on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Murphy

- Murphy

16 Mar 2025 14:03

- tsaG

- tsaG

16 Mar 2025 13:59

No parameters forwarded to M6 script? was created by tsaG

No parameters forwarded to M6 script?

Category: QtPyVCP

- TooTall18T

16 Mar 2025 13:39

Replied by TooTall18T on topic Vscode gcode highlight and formatter, with subroutine support

Vscode gcode highlight and formatter, with subroutine support

Category: O Codes (subroutines) and NGCGUI

- tommy

- tommy

16 Mar 2025 13:02 - 16 Mar 2025 14:10

Replied by tommy on topic STEPLEN STEPSPACE time for Bergerda AC servo driver

STEPLEN STEPSPACE time for Bergerda AC servo driver

Category: General LinuxCNC Questions

- M4MazakUser

- M4MazakUser

16 Mar 2025 11:26

Replied by M4MazakUser on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- JT

16 Mar 2025 11:14

Replied by JT on topic Edit config file from 2.9.3 in stepconf 2.9.4

Edit config file from 2.9.3 in stepconf 2.9.4

Category: Installing LinuxCNC

- Aciera

16 Mar 2025 10:50 - 16 Mar 2025 10:52

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- papagno-source

- papagno-source

16 Mar 2025 09:49

Replied by papagno-source on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Wusel

- Wusel

16 Mar 2025 08:16

Replied by Wusel on topic Motor 0 Positionsfehler

Motor 0 Positionsfehler

Category: Advanced Configuration

Time to create page: 0.451 seconds