Search Results (Searched for: )

- vre

- vre

14 Mar 2025 16:20 - 14 Mar 2025 16:25

Replied by vre on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

- royka

- royka

14 Mar 2025 16:10

- Grotius

14 Mar 2025 15:45

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- RobotMatic

14 Mar 2025 15:04

- unknown

- unknown

14 Mar 2025 14:45

Replied by unknown on topic Funny message when reply to a topic

Funny message when reply to a topic

Category: Forum Questions

- PCW

14 Mar 2025 14:43

Replied by PCW on topic 7i95 randomly throws error with raspi b

7i95 randomly throws error with raspi b

Category: Driver Boards

- atrex77

14 Mar 2025 14:36

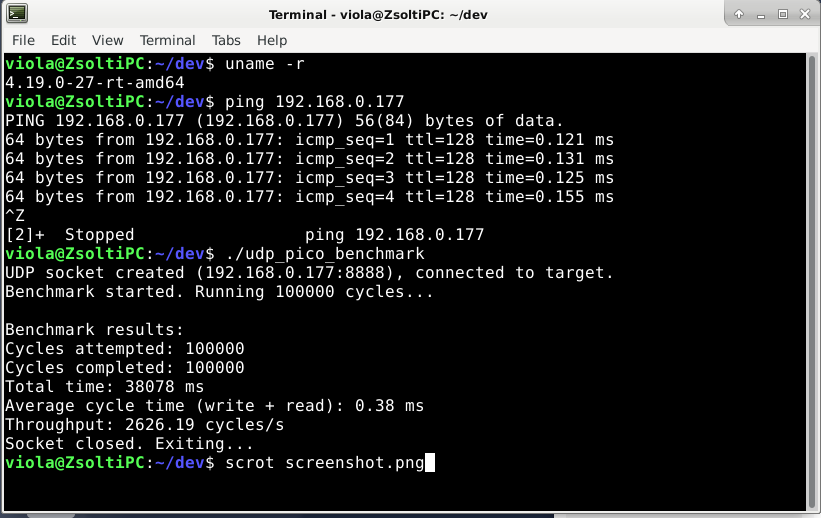

Replied by atrex77 on topic Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Category: General LinuxCNC Questions

- PCW

14 Mar 2025 14:23

Replied by PCW on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

- webbyguy

- webbyguy

14 Mar 2025 13:48

Replied by webbyguy on topic Results of latency test, list of computers tested for use with LinuxCNC

Results of latency test, list of computers tested for use with LinuxCNC

Category: Computers and Hardware

- nobby42

- nobby42

14 Mar 2025 13:48 - 14 Mar 2025 13:49

Migration von 2.8.4 auf 2.9.4 was created by nobby42

Migration von 2.8.4 auf 2.9.4

Category: Deutsch

- FabianB

14 Mar 2025 13:45

Replied by FabianB on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- tommylight

14 Mar 2025 13:36

Replied by tommylight on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Category: Show Your Stuff

- tommylight

14 Mar 2025 13:32

Replied by tommylight on topic Funny message when reply to a topic

Funny message when reply to a topic

Category: Forum Questions

- tommylight

14 Mar 2025 13:29

Replied by tommylight on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- timo

- timo

14 Mar 2025 13:09

Time to create page: 0.286 seconds