Search Results (Searched for: Proma THC)

26 Mar 2024 10:48 - 26 Mar 2024 10:50

Replied by LinuxPlasma on topic Can not wrap my head around homing

Can not wrap my head around homing

Category: Basic Configuration

22 Mar 2024 23:21 - 23 Mar 2024 23:24

Can not wrap my head around homing was created by LinuxPlasma

Can not wrap my head around homing

Category: Basic Configuration

24 Feb 2024 15:28 - 24 Feb 2024 15:33

23 Feb 2024 23:14

05 Feb 2024 18:19

Replied by tommylight on topic Use parallelport and mesa card together

Use parallelport and mesa card together

Category: General LinuxCNC Questions

19 Dec 2023 21:17 - 19 Dec 2023 21:27

Replied by BrysonW on topic Remora - ethernet NVEM cnc board

Remora - ethernet NVEM cnc board

Category: Computers and OS's

12 Dec 2023 05:21 - 12 Dec 2023 05:32

Replied by BrysonW on topic Remora - ethernet NVEM cnc board

Remora - ethernet NVEM cnc board

Category: Computers and OS's

23 Sep 2023 15:40 - 23 Sep 2023 15:43

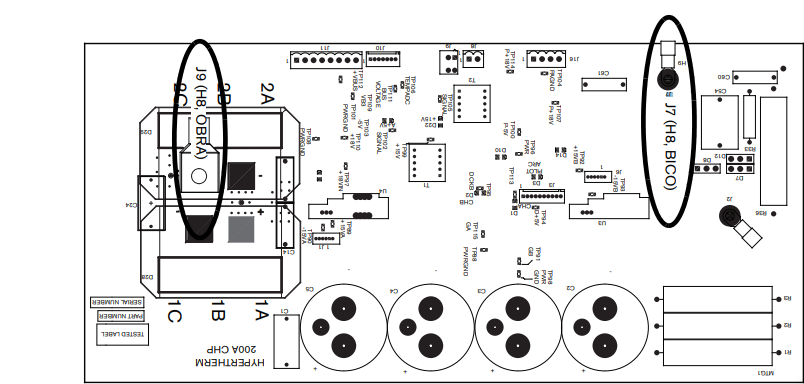

Replied by santy on topic Hypertherm MAX PRO 200 CNC Connections - Quick Question

Hypertherm MAX PRO 200 CNC Connections - Quick Question

Category: Plasma & Laser

29 Aug 2023 17:24

Replied by tommylight on topic French Esab Ultrarex UXD-P2000 update to MESA

French Esab Ultrarex UXD-P2000 update to MESA

Category: General LinuxCNC Questions

14 Jul 2023 12:51

Replied by tommylight on topic First sparks - Thanks everyone!

First sparks - Thanks everyone!

Category: Plasma & Laser

14 Jul 2023 12:44

Replied by alangibson on topic First sparks - Thanks everyone!

First sparks - Thanks everyone!

Category: Plasma & Laser

14 Jul 2023 10:57

Replied by rodw on topic First sparks - Thanks everyone!

First sparks - Thanks everyone!

Category: Plasma & Laser

14 Jul 2023 08:29 - 14 Jul 2023 08:32

First sparks - Thanks everyone! was created by alangibson

First sparks - Thanks everyone!

Category: Plasma & Laser

24 Jun 2023 09:48

Replied by rodw on topic Qtplasmac with proma thc 150 Z axis up and down too quick!

Qtplasmac with proma thc 150 Z axis up and down too quick!

Category: Plasmac

23 Jun 2023 13:54

Replied by RRicardo on topic Qtplasmac with proma thc 150 Z axis up and down too quick!

Qtplasmac with proma thc 150 Z axis up and down too quick!

Category: Plasmac

Time to create page: 0.787 seconds