Another plasma component...

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

17 Jun 2019 00:20 - 17 Jun 2019 00:26 #137076

by Grotius

Replied by Grotius on topic Another plasma component...

@Rod,

If you look at how to load the full g-code line real time into the component as character.

You or i can do the string parsing and can provide huge info about different linux code snippets, related to circles, corners, lead-in's, lead-out's etc. Almost on the fly. ( most of the c code logic i have made in the past for the dxf decoder )

Poor old Phill will never get to build his machine.

He has time, and he has a peleton of subscribers.

If you look at how to load the full g-code line real time into the component as character.

You or i can do the string parsing and can provide huge info about different linux code snippets, related to circles, corners, lead-in's, lead-out's etc. Almost on the fly. ( most of the c code logic i have made in the past for the dxf decoder )

Poor old Phill will never get to build his machine.

He has time, and he has a peleton of subscribers.

Last edit: 17 Jun 2019 00:26 by Grotius.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Jun 2019 01:38 #137080

by phillc54

Cheers, Phill.

Replied by phillc54 on topic Another plasma component...

Fixed and pushed, thanks Tom.I am not here, but anyway

Did a quick browse through the documentation and found this

M67 E3 P0 would set the velocity to 40% of requested speed

M67 E3 P40 would set the velocity to 40% of requested speed.

M67 E3 P60 would set the velocity to 60% of requested speed.

M67 E3 P100 would set the velocity to 40% of requested speed

Cheers, Phill.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Jun 2019 01:51 #137082

by phillc54

Cheers, Phill.

Replied by phillc54 on topic Another plasma component...

I do have a mod to the gcode parser that can find arcs BUT:Poor old Phill will never get to build his machine.. He is already parsing the gcode looking for invalid toolsets so now he needs to look for arcs as well!

- All X/Y positions must be absolute. i.e. must be G90 mode.

- All I/J offsets must be relative. i.e. must be G91.1 mode.

- It is not fully tested.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

17 Jun 2019 10:16 #137113

by rodw

Well its been an eventful night! I was blessed by a phone call from Tommy which was nice. He was a bit worried about security if he contacted me via my web site but rest assured we use a leading, highly secure cloud hosted ecommerce provider called neto which is 51% owned by Telstra, our monopolistic telecommunications giant here in Australia. If they have any security gaps, the whole country will be in trouble!

Then when I hung up, I had an email back from Les Newell the Sheetcam developer and he's given me some code to insert to turn off the adaptive feed after an arc. I'll get to trying it in the next couple of days as its more than just a couple of lines.

Replied by rodw on topic Another plasma component...

I think the problem may arise how to turn off the reduced speed as the Sheetcam cutting rule can't turn this off as there is no "After Arc" rule. It might be possible to add a M67 E3 Q1.0 in the Sheetcam onMove() method to reset the speed to 100%. I'll go back to Les Newell at Sheetcam and see what he can come up with.I have a question about program flow :

Question :

Is this calculated back into the component? Or maybe i miss something here. Is there a short program flow available how i can understand the interpretation of the M67 codes. So far i think. The M67 values are predifined at program load, are they corrected and calculated real time during program execution?

Well its been an eventful night! I was blessed by a phone call from Tommy which was nice. He was a bit worried about security if he contacted me via my web site but rest assured we use a leading, highly secure cloud hosted ecommerce provider called neto which is 51% owned by Telstra, our monopolistic telecommunications giant here in Australia. If they have any security gaps, the whole country will be in trouble!

Then when I hung up, I had an email back from Les Newell the Sheetcam developer and he's given me some code to insert to turn off the adaptive feed after an arc. I'll get to trying it in the next couple of days as its more than just a couple of lines.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

17 Jun 2019 10:52 - 17 Jun 2019 10:53 #137115

by bevins

Replied by bevins on topic Another plasma component...

I thought Plasmac was only working in gmocappy for now....

Last edit: 17 Jun 2019 10:53 by bevins.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Jun 2019 11:45 #137117

by phillc54

Cheers, Phill.

Replied by phillc54 on topic Another plasma component...

Axis was brought back a little while ago after most of the bugs were ironed out.I thought Plasmac was only working in gmocappy for now....

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

17 Jun 2019 19:31 #137149

by tommylight

Regards,

Tom

P.S.

Just did a short video about Mesa 7i92 and an Acer laptop that works perfectly with Linuxcnc even when wired through a network switch, uploading it to YouTube and starting a new thread for more info.

Replied by tommylight on topic Another plasma component...

Hmmmmm not exactly, I said in general I am wary of not typing my info on web sites, the usual network admin paranoia. In your case I literally saw your personal phone number and thought " oh good I'll call him tomorrow! "

Well its been an eventful night! I was blessed by a phone call from Tommy which was nice. He was a bit worried about security if he contacted me via my web site but rest assured we use a leading, highly secure cloud hosted ecommerce provider called neto which is 51% owned by Telstra, our monopolistic telecommunications giant here in Australia. If they have any security gaps, the whole country will be in trouble!

Regards,

Tom

P.S.

Just did a short video about Mesa 7i92 and an Acer laptop that works perfectly with Linuxcnc even when wired through a network switch, uploading it to YouTube and starting a new thread for more info.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

17 Jun 2019 20:14 #137154

by Grotius

Replied by Grotius on topic Another plasma component...

@Phill,

You can post your code over here. G90 is good.

I and J offset's are the core members to be calculated when using snippet's for circles and arc's in all 4 quadrant's.

If it's G90.1 or G91.1 does not matter for me at this moment.

I have not looked so far myself to load in g-code line's into the real time memory and do some calculation's with it relating to code snippet's. But it's overall a interesting item. The probe over distance has also become a very succesful item. So why not adapt some code snippets.

The only worry i have is to keep it a real time interacting solution (component solution)

I don't like pre defined g-code solution's like multiple g-code lines for a simple probing sequence etc.

Then user cannot change it real time in the field at the machine.

You can post your code over here. G90 is good.

I and J offset's are the core members to be calculated when using snippet's for circles and arc's in all 4 quadrant's.

If it's G90.1 or G91.1 does not matter for me at this moment.

I have not looked so far myself to load in g-code line's into the real time memory and do some calculation's with it relating to code snippet's. But it's overall a interesting item. The probe over distance has also become a very succesful item. So why not adapt some code snippets.

The only worry i have is to keep it a real time interacting solution (component solution)

I don't like pre defined g-code solution's like multiple g-code lines for a simple probing sequence etc.

Then user cannot change it real time in the field at the machine.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

21 Jun 2019 04:05 - 21 Jun 2019 04:29 #137448

by phillc54

Replied by phillc54 on topic Another plasma component...

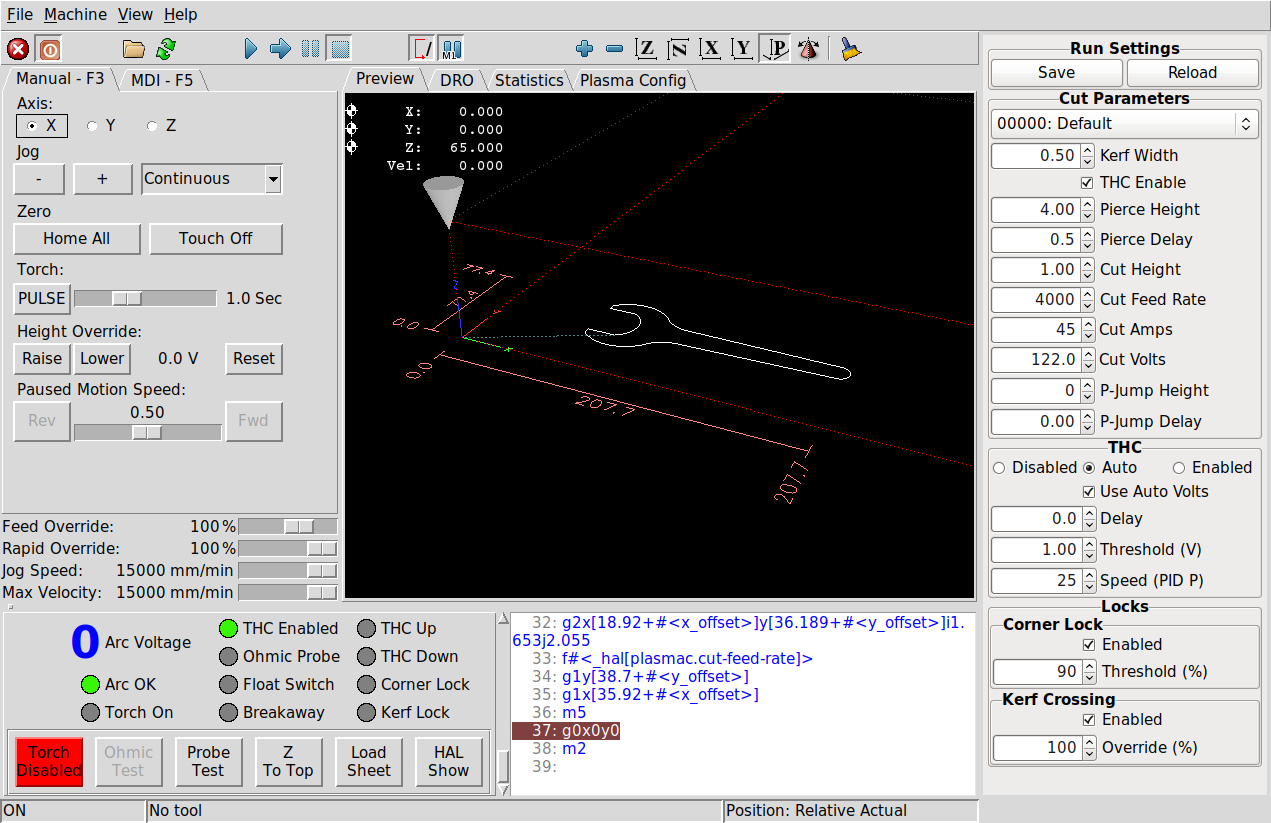

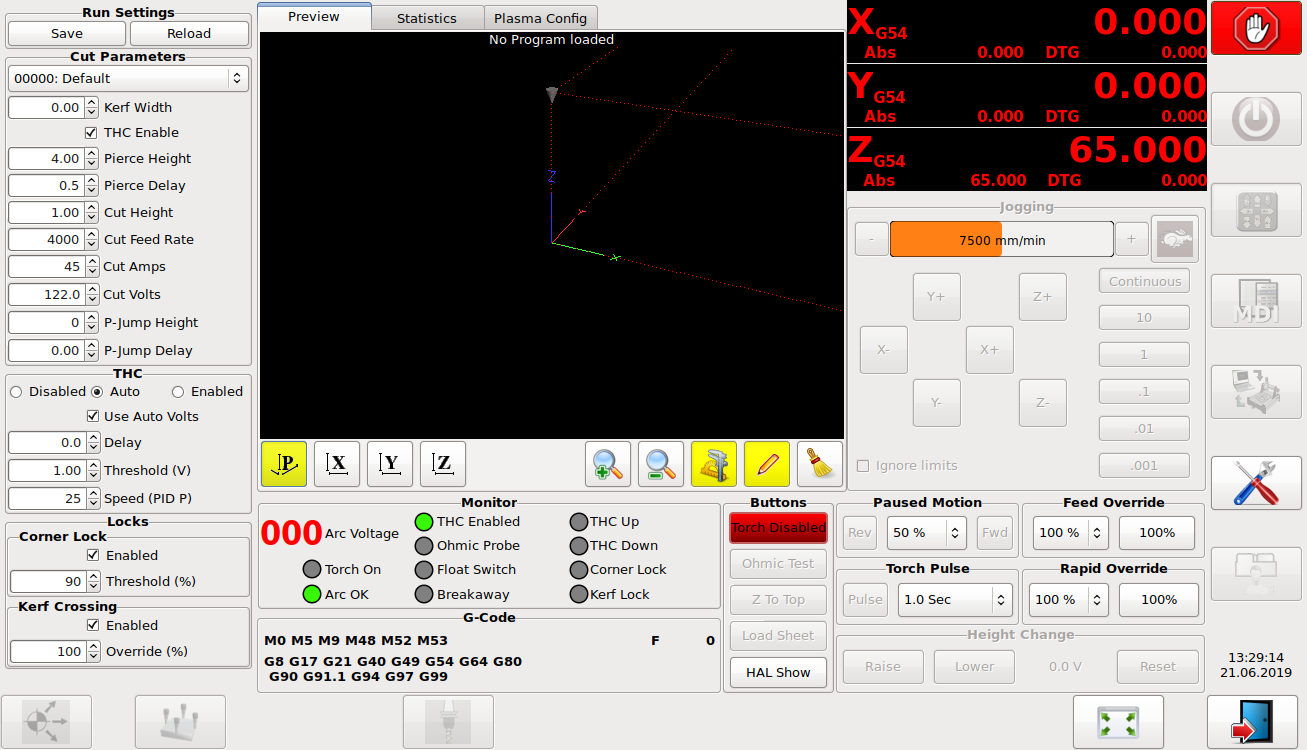

For all you folk with widescreen monitors I have made a Run Panel that shows at the side of the GUI rather than as a tab.

To use this do an upgrade then edit your ini file.

For Axis, the panel sits at the right hand side and at the moment you will get a permanent error in the terminal saying it is waiting for a component to be ready. This doesn't appear to affect the machine operation and there is a pull request in the LinuxCNC repo for a fix.

Comment out the two EMBED lines an uncomment the GLADEVCP line.

For Gmoccapy the panel sits at the left hand side.

Comment out the first three EMBED lines and uncomment the next three EMBED lines.

Axis:

Gmoccapy:

Cheers, Phill.

To use this do an upgrade then edit your ini file.

For Axis, the panel sits at the right hand side and at the moment you will get a permanent error in the terminal saying it is waiting for a component to be ready. This doesn't appear to affect the machine operation and there is a pull request in the LinuxCNC repo for a fix.

Comment out the two EMBED lines an uncomment the GLADEVCP line.

# run panel in tab behind preview

EMBED_TAB_NAME = Plasma Run

EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x {XID} -u ./plasmac_run.py -H plasmac_run.hal plasmac_run_tab.glade

# run panel in panel on right side

#GLADEVCP = -c plasmac_run -u ./plasmac_run.py -H plasmac_run.hal plasmac_run_panel.gladeFor Gmoccapy the panel sits at the left hand side.

Comment out the first three EMBED lines and uncomment the next three EMBED lines.

# run panel in tab behind preview

EMBED_TAB_NAME = Plasma Run

EMBED_TAB_LOCATION = ntb_preview

EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x {XID} -u ./plasmac_run.py -H plasmac_run.hal plasmac_run_tab.glade

# run panel in panel on left side

#EMBED_TAB_NAME = Plasma Run

#EMBED_TAB_LOCATION = box_left

#EMBED_TAB_COMMAND = gladevcp -c plasmac_run -x {XID} -u ./plasmac_run.py -H plasmac_run.hal plasmac_run_panel.gladeAxis:

Gmoccapy:

Cheers, Phill.

Attachments:

Last edit: 21 Jun 2019 04:29 by phillc54.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

21 Jun 2019 08:08 #137462

by rodw

Replied by rodw on topic Another plasma component...

Well it just so happens I did a bit more work on my machine while Phill was doing this upgrade.

Just a heads up you may need to manually copy the new display settings into your ini file. I was getting gcode errors becasue I did not have a feed rate because the whole plasma run tab was missing! The new Gmoccappy wide screen works well.

The other issue I had was that the new HAL connections to allow adaptive feed and disableTHC features.

Anyway, the good news is once I had pins that actually got the adaptive feed working, I sorted out some code snippets and cutting rules for holes for Sheetcam and it all works nicely.

Just a heads up you may need to manually copy the new display settings into your ini file. I was getting gcode errors becasue I did not have a feed rate because the whole plasma run tab was missing! The new Gmoccappy wide screen works well.

The other issue I had was that the new HAL connections to allow adaptive feed and disableTHC features.

Anyway, the good news is once I had pins that actually got the adaptive feed working, I sorted out some code snippets and cutting rules for holes for Sheetcam and it all works nicely.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.242 seconds