Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Rod,

I connected an analog pin to the plasmac component to vary the adaptive feed pin and it works great in a sim. I just have to figure out how to integrate it into the config.

Cheers, Phill.

Thats awesome Phill. I think that will be a powerful feature moving forward. Because its a Hal only change, maybe it could be contained in a hal file that could be commented out in the ini. (just an idea). But if its able to be incorporated without altering current behaviour, maybe you just build it in.

If you can push it out tomorrow, I'll try and test it over the weekend as I need to rebuild my config with all of the new changes.

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

- Posts: 339

- Thank you received: 96

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

When Catterpillar has started a plasma arc at 200 amp's, to cut a piece for a modification for a new crane. for a customer.

When they not know the voltage chart's not for sure, they can disable the up down torch movement. It will cut the piece with no

z axis correction's. Just like cutting with oxy fuel. But linuxcnc can make real time correction's to oxy fuel with a up and down button.

So no worry at all.

The best condition's are on a holiday, hanging on a parachute !!

Thats awesome Phill. I think that will be a powerful feature moving forward.

Yes, for sure, but why at the end of the thc implentation?

It still would not listen to a negative -1 job unless it's a neutral glade implementation without the speedwidget implementation

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

So the intent with adaptive-feed is to slow the velocity down for arcs with a radius less than a certain value. This will cause the velocity to be lower than the cornerlock threshold so THC will be locked. This velocity needs to be different for a range radius values.

Grotius,

I'm not quite sure what you mean by:

Yes, for sure, but why at the end of the thc implentation?

It still would not listen to a negative -1 job unless it's a neutral glade implementation without the speedwidget implementation

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I would also like to see something like that, it would make things easier to understand.As a reference can anyone specify the conditions when it will be best to disable thc? Like a handy chart of mtrl vs hole size vs feed rate etc.

But... apparently plasma is not supposed to be easy

Cheers, Phill

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

Thanks guys

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Yes, that is how it is supposed to work. You will need to adjust the Delay value in the THC frame of the run tab to tune it to your requirements, probably start at about 1 second and move around from there. This is to give the arc voltage time to stabilise before it obtains the sample voltage.So quick question. I was reading through the readme because I was wondering if “auto volts” did what I hoped it would. There is not much listed about it but what exzactly is it and how is it properly used. I’m hoping it’s somthing that will sample the stable voltage right after it starts cutting at a specified height. It would then associate the cutstart height with the sampled voltage and hold that voltage.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

While this isn't Plasmac specific it seems we do drift into general plasma procedures often here. If you want details on cutting accurate small holes look up the sales sheets on Hypertherm's "True Hole Technology" also look on plasmaspider, user seanp has posted extensively on his work using simple air plasma.

The generally accepted method to get good holes from 37mm dia. and down to material thickness with minimal taper using an air plasma is:

1, Use recommended cutting current for consumables.

2. Use fixed (no THC) recommended cutting height for consumables.

3. Cut at 60% to 70% of recommended feed rate for consumables and material.

4. Start lead in at or near center of hole.

5. Use perpendicular lead in.

6. No lead out, either a slight over burn or early torch off depending on what works best for you.

You will need to experiment to get exact hole size because the kerf with this method will be wider than your usual straight cut.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

So quick question. I was reading through the readme because I was wondering if “auto volts” did what I hoped it would. There is not much listed about it but what exzactly is it and how is it properly used. I’m hoping it’s somthing that will sample the stable voltage right after it starts cutting at a specified height. It would then associate the cutstart height with the sampled voltage and hold that voltage. So if I said .06 cut height it would start the cut at .060 off the sheet and remember that voltage and try and hold it till it has to start another cut. I guess the issue I have is I’m using a plasma thatsnot “rated” for cnc so I’m kinda making up voltages as I go. It would be much handier to spec heights. And considering I’m doing my ohmic sencing right off the nozzle it would alow for electrode wear and compensate by upping the voltage.

Thanks guys

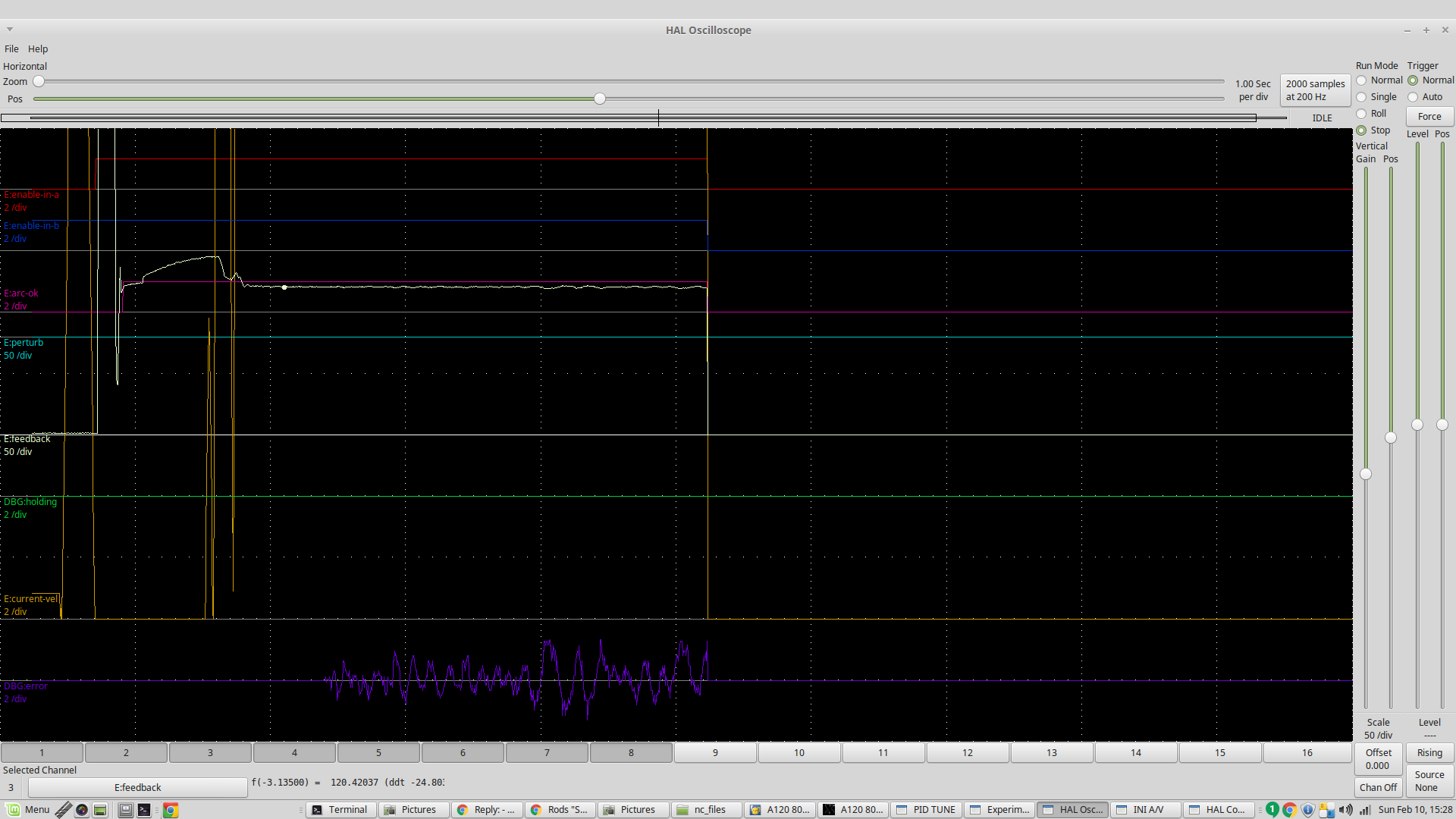

JTK, If you click through to the Gmocappy setup screen you can fire up halscope and gather some data about your machine while cutting. Here is an example I stole from my Spaceship plasma thread

Here the green line is the cut voltage and you can see it peak on the pierce and than fall back to a stable voltage.

The blue line represents the error between actual and commanded voltage which starts as the THC turns on (at the white dot) 1.5 seconds into the cut. Its that initial peak that you must wait out before enabling torch voltage sampling. I might add, I have been doing this for a long time pre plasmac with my own component. I've never relied on the cut chart voltage. I settled on 1.5 seconds before sampling and that does not change much with material thickenss or amperage.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

forum.linuxcnc.org/show-your-stuff/32029...tter-build?start=460

Please Log in or Create an account to join the conversation.