Another plasma component...

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

29 Jul 2019 21:29 #140921

by rodw

Something like this?

I just progrrammed a gcode macro in Gmoccappy to move to the offset and touch off X & Y

All I did was fire the torch to create a spot at position 0,0 and jog precisely to 0,0 to determine the required offset.

See: forum.linuxcnc.org/show-your-stuff/32029...ild?start=470#137114

Read down a bit as there is more detail.

Replied by rodw on topic Another plasma component...

So I don’t know if this belongs here or in a new post. If it needs to be moved let me know and I will delete it and start a thread.

Im not a Linux programming genius, hell I could barely manage getting it installed. I don’t know if what I’m wanting can be added to the plasmaC or would need to be its own thing. The steel I cut is all high dollar stuff. Yesterday I cut up a 11”x23” sheet of stainless that cost me $100. So a mess up can be really costly and go down hill fast. Now I can’t cut it real fast as I’m running a 30xp and sitting at around 20”/min. I’m using sheetcam to nest and save it as a number attached to that sheet so I can load it back up and add more parts later and know what’s already been cut out. My issue is finding the exact starting corner. I have been using a square to get it square to the table and then bringing the torch down and moving over till I just barely touch the edge. Then set this as -.375 in g54 for x and y. This gives my just enough to clear the edge of the sheet. I do this because I set the edge of the parts at the edge of the sheet in sheet cam. This has eliminated the fudge factor guessing for me.

Yesterday I was wondering why could I not have a touch off button. The torch has ohmic so it could use that. Back when I ran cnc machines the new hass mills would load up a touch off tool. You would manually eyeball it over the corner and hit the touch off button. It would come down in the Z and find the top. Then move over in the X any Y a programmed amount and then come down a set amount and move over till it touches the side. It would set that as X and then retract and do the same for Y. It would then enter these numbers into the G54 offset.

If I could somehow build this function into my machine I would be tickled pink. We won’t bring up the other feature that would put it over the top. Well why not just mention it at least. Another machine I ran would touch off in 2 places on an edge and rotate the axis in the machine so the x and y would like up parallel to the sheet/part.

Something like this?

I just progrrammed a gcode macro in Gmoccappy to move to the offset and touch off X & Y

All I did was fire the torch to create a spot at position 0,0 and jog precisely to 0,0 to determine the required offset.

See: forum.linuxcnc.org/show-your-stuff/32029...ild?start=470#137114

Read down a bit as there is more detail.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

29 Jul 2019 21:31 #140922

by tommylight

Replied by tommylight on topic Another plasma component...

@JTknives

Probe screen ??? You already have the sensor, so a bit of editing and it should work.

The only problem is the torch need some empty space around the corner of the material to go below material and does your nozzle/shield extend enough outside to touch the sides of the material.

Probe screen ??? You already have the sensor, so a bit of editing and it should work.

The only problem is the torch need some empty space around the corner of the material to go below material and does your nozzle/shield extend enough outside to touch the sides of the material.

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

29 Jul 2019 22:00 #140924

by JTknives

Replied by JTknives on topic Another plasma component...

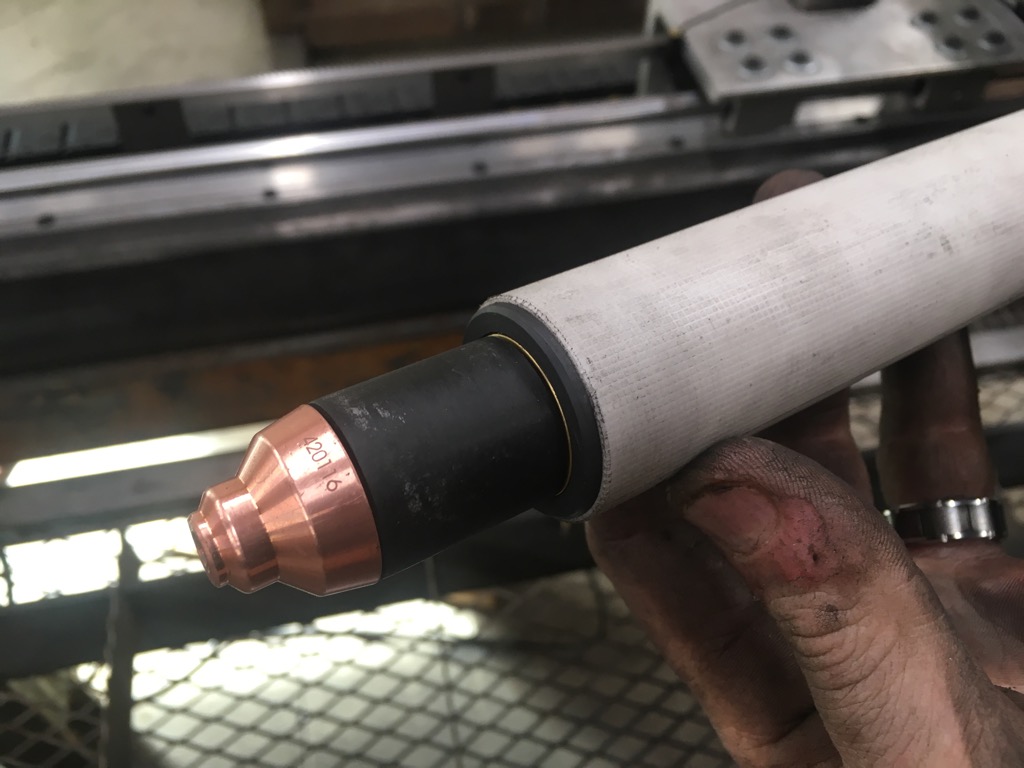

Yeah my shield I use is the standard shield that I have lathed off the nibs on the end. The shield sits about .01+ below the nozzle. I was using it with fine cut and with the fine cut shield but the touch off was damaging the nozzle so switched back to standard cut. I think the nozzle part is .625 diameter and sticks down about a 1/4”. I always hang the edge of the sheet over the slat edge.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7251

29 Jul 2019 23:04 #140930

by tommylight

Replied by tommylight on topic Another plasma component...

That should do just fine, use the lower part for sensing as it looks not to be tapered, that way you get consistent results.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Jul 2019 23:22 #140931

by phillc54

Replied by phillc54 on topic Another plasma component...

Yes Rod I sure will. The default will be disabled. It is only for those of us that don't have that feature available in a post processorPhill, if you come back to this, could you make sure there is something that can disable this parsing? Somehow, it does not feel right to build features that modify the Gcode as a user might not want to enable this type of behaviour.

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 63

30 Jul 2019 01:53 #140933

by grijalvap

Replied by grijalvap on topic Another plasma component...

Hi

thanks for your help.

Attached is the last version of the component I'm Using to communicate with the Hyperterm 85 plasma

please feel free to use, modify and distribute it.

Also let me know if you have any doubt about the code, or how I use it

thanks.

thanks for your help.

Attached is the last version of the component I'm Using to communicate with the Hyperterm 85 plasma

please feel free to use, modify and distribute it.

Also let me know if you have any doubt about the code, or how I use it

thanks.

The following user(s) said Thank You: mkardasi, rodw, islander261

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

30 Jul 2019 03:27 - 30 Jul 2019 03:30 #140934

by islander261

Replied by islander261 on topic Another plasma component...

JTknives

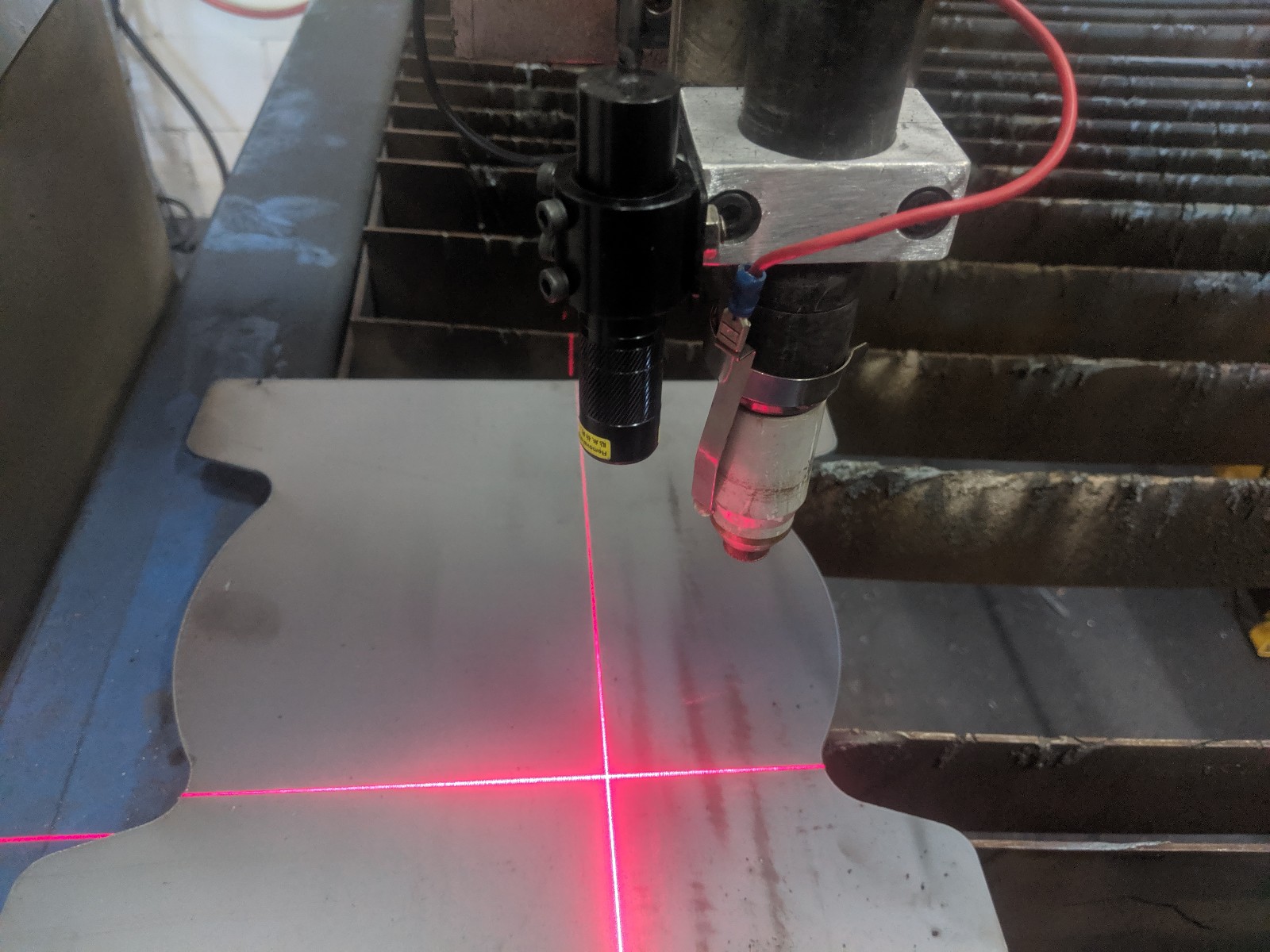

I have a setup similar to Rod's and find it works very nice. I can use it to square the work piece to the machine motion and set the work piece zero. My cross hairs intersect under the nozzle of my torch. I seem to remember using two $5 laser line generators from ebay. I am sure there is a photo of my setup someplace in this forum topic.

Pedro

Thank you for sharing.

John

I have a setup similar to Rod's and find it works very nice. I can use it to square the work piece to the machine motion and set the work piece zero. My cross hairs intersect under the nozzle of my torch. I seem to remember using two $5 laser line generators from ebay. I am sure there is a photo of my setup someplace in this forum topic.

Pedro

Thank you for sharing.

John

Last edit: 30 Jul 2019 03:30 by islander261.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

30 Jul 2019 04:30 #140935

by rodw

Phill, it would be cool to include this in your distro so it becomes part of Linuxcnc. I'm not sure how you go about writing man pages for python user space components.

Replied by rodw on topic Another plasma component...

Hi

thanks for your help.

Attached is the last version of the component I'm Using to communicate with the Hyperterm 85 plasma

please feel free to use, modify and distribute it.

Also let me know if you have any doubt about the code, or how I use it

thanks.

Phill, it would be cool to include this in your distro so it becomes part of Linuxcnc. I'm not sure how you go about writing man pages for python user space components.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

30 Jul 2019 04:38 #140936

by rodw

To square the cross hairs you just need to make an L shaped cut, place over the corner and align the crosshairs. The basic 5 volt laser modules are < usually $5.00 on ebay. Something like this

www.ebay.com.au/itm/Laser-Module-Red-Cro...rNZ6g&frcectupt=true

I just thought using 2 line lasers intersecting under the tip like John does was too much work! There are plenty of examples on you tube

Replied by rodw on topic Another plasma component...

JTknives

I have a setup similar to Rod's and find it works very nice.

John

To square the cross hairs you just need to make an L shaped cut, place over the corner and align the crosshairs. The basic 5 volt laser modules are < usually $5.00 on ebay. Something like this

www.ebay.com.au/itm/Laser-Module-Red-Cro...rNZ6g&frcectupt=true

I just thought using 2 line lasers intersecting under the tip like John does was too much work! There are plenty of examples on you tube

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

30 Jul 2019 15:01 #140953

by andypugh

I think you just need to write an asciidoc documentL

github.com/LinuxCNC/linuxcnc/blob/master...rc/drivers/vfs11.txt

is an example.

Then add it to the submakefile:

github.com/LinuxCNC/linuxcnc/blob/2.8/docs/src/Submakefile

Replied by andypugh on topic Another plasma component...

I'm not sure how you go about writing man pages for python user space components.

I think you just need to write an asciidoc documentL

github.com/LinuxCNC/linuxcnc/blob/master...rc/drivers/vfs11.txt

is an example.

Then add it to the submakefile:

github.com/LinuxCNC/linuxcnc/blob/2.8/docs/src/Submakefile

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.379 seconds