Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

John, you are responsible for confirming that Linuxcnc can do anything you think off, and do that in several ways, usually. My complaints are regarding new users and the ensuing workload for Phill and the others here in the forum. It would have been much better to have a simpler version, ready for use by them by now, and continue working on the actual version. That would have left users the option to choose, and not be thrown on the deep end to start with.

Just noticed, sorry for hijacking your thread, Rod.

Personally i can use anything and modify it to my liking, but i can not use Plasmac on clients machines anymore since people here where i live do not wait for a week or two to have their machine fixed, at encountering any issue, i have to leave whatever i am doing and go check and fix whatever is needed.

Back on topic......hmmm.... at last,

Regarding holes, usually i avoid anything under 30mm for a good cut, and making small holes and later drilling them to size is not an option as it tends to mess up drill bits on short notice. This is for parts cut on a water table, have not tried to do that with cuts on air, maybe that will work as the material would cool down slower so the inevitable hardening of the cut would have to be less of an issue.

Also will have to make 2 holders for the new torch heads i got several months back, but had not time to put them to use. Unfortunately derlin or HDPE is very expensive here and finding big parts for those holders is hard and way more expensive. Making an attempt tomorrow, wondering how much of a shock the price will be.

Regards,

Tom

P.S.

In the mean time of doing other things, i am also building a small frame for a plasma cutter with the cheapest parts i can find here, with round linear rails all over, belts and stuff, but trying to make it look better as a whole. Size 55X95CM.

Tommy, apology accepted. I kinda agree, Plasmac is not quite ready for prime time for customers but its getting close I think. I really am very grateful that Phill has taken up the challenge to roll up all of the developments and experiments that have been undertaken in this open source group. I think John has made some valuable contributions over the last few years and really it was his decision to adopt it was what pushed so many people to try it. On the subject of holes, in 2mm mild steel, I've been able to get acceptable quality clearance holes down to M6 but drilled out 200 slightly undersize 10 mm holes for nutserts today. I have been getting these laser cut assembled and powder coated, partly becasue I was lazy and one part has a slight bend in it.

but with Plasmac's help, Ive got a set of 100 going out to powder coating in the morning. I bought one of these coll little vice brakes and it worked a treat to bend it/

www.machineryhouse.com.au/V052

It really must be frustrating to live in a forgotten country. I use so much HDPE, I got so sick of chasing up the material so I bought 920 kg of it out of China but they cut it down to 50mm pieces for me. While I was at it, I got some acetal (delrin) parts I used to machine. I had a look in my Australia Post account but sadly I can't post to you. I do have very good rates with a couple of plastic suppliers as well as a 40% discount on postage rates so if you ever get stuck, let me know. I would only be too happy to help! I can buy HDPE and Acetal in 1 metre lengths.

Attachments:

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

i ga one that size in the education center

In the mean time of doing other things, i am also building a small frame for a plasma cutter with the cheapest parts i can find here, with round linear rails all over, belts and stuff, but trying to make it look better as a whole. Size 55X95CM.

I am going to attempt to build a small one as well so looking forward to see yours.To gain Ideas .

on about 700Euros including Plasma cutter and Table

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

It is also frustrating that so many web sites do not list my country at all, so I order through friends in other countries.

Also I can find HDPE in only 20x30x0.8 cm at some kitchen stuff stores here, used for chopping food or whatever .

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

Rod, thank you very much.

It is also frustrating that so many web sites do not list my country at all, so I order through friends in other countries.

Also I can find HDPE in only 20x30x0.8 cm at some kitchen stuff stores here, used for chopping food or whatever .

Its not actually the website that is letting you down, it is the post office in some countries (like ours) that don't list you as a destination. I've only ever bought plastic rods, generally in 60mm and 75mm and acetal in 32 mm. A full sheet of HDPE is 2.4 x 1200 but sometimes I see they have offcuts.

Please Log in or Create an account to join the conversation.

- stevec

- Offline

- New Member

-

- Posts: 6

- Thank you received: 0

At 1 minute 25 secs of the video around 9 o'clock position on the machine - have you got critters living in the water in the plasma tray?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

It is also frustrating that so many web sites do not list my country at all

No problem at all. You are OEM of TD and HP already without noticing. Did you ask me something?

My connection's in Servie and Russia are good. But Tommy is my friend. His country has the perfect tax rate.

Bosnie is perfect to start up a company !!! Australia is also good to start up a company for plasma cutter's !!

Do we have a point over here?

Rodw has a existing company in car parts so far i know. So set up a plasma company with a linux based software platform can

be a good stratagy for Rod. Then Rod can finally buy a mclaren from England, or a Rolls Roy's let's say this one :

Linux is powerfull. It attrack's money with the flow. Don't let Swiftcut rule your life. It's a company pure based on investor's without any soft or hardware knowlegde. That will kill them on therm for sure. Keep in mind my words. Purelogic is a russian company with the same perspective stratagie. A more intelligent company related to Swiftcut, but way to expensive.

When you have the car. Put your usb device in it and ride along. Good music at the course.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

No way! The thril would have just started, big time!

Life has been cruel to me lately, the last fast car I drove had only 508 HP! That was several years ago, now I drive a diesel ! At least I get less speeding tickets! A lot less! Damn, I must have payed over 300 speeding tickets in my life time! No point system here and the min and max values where between 25 and 85 euros, last year all that changed, minimum is 200 and 1 point lost !

So in a way I was very lucky!

Rod, sorry, off topic again. We owe you a lot of beers !

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11732

- Thank you received: 3973

the last fast car I drove had only 508 HP! That was several years ago, now I drive a diesel ! At least I get less speeding tickets! A lot less!

Tommy, I think you need to upgrade to a diesel 4WD and then you can spend all your spare money with me making it go even slower!

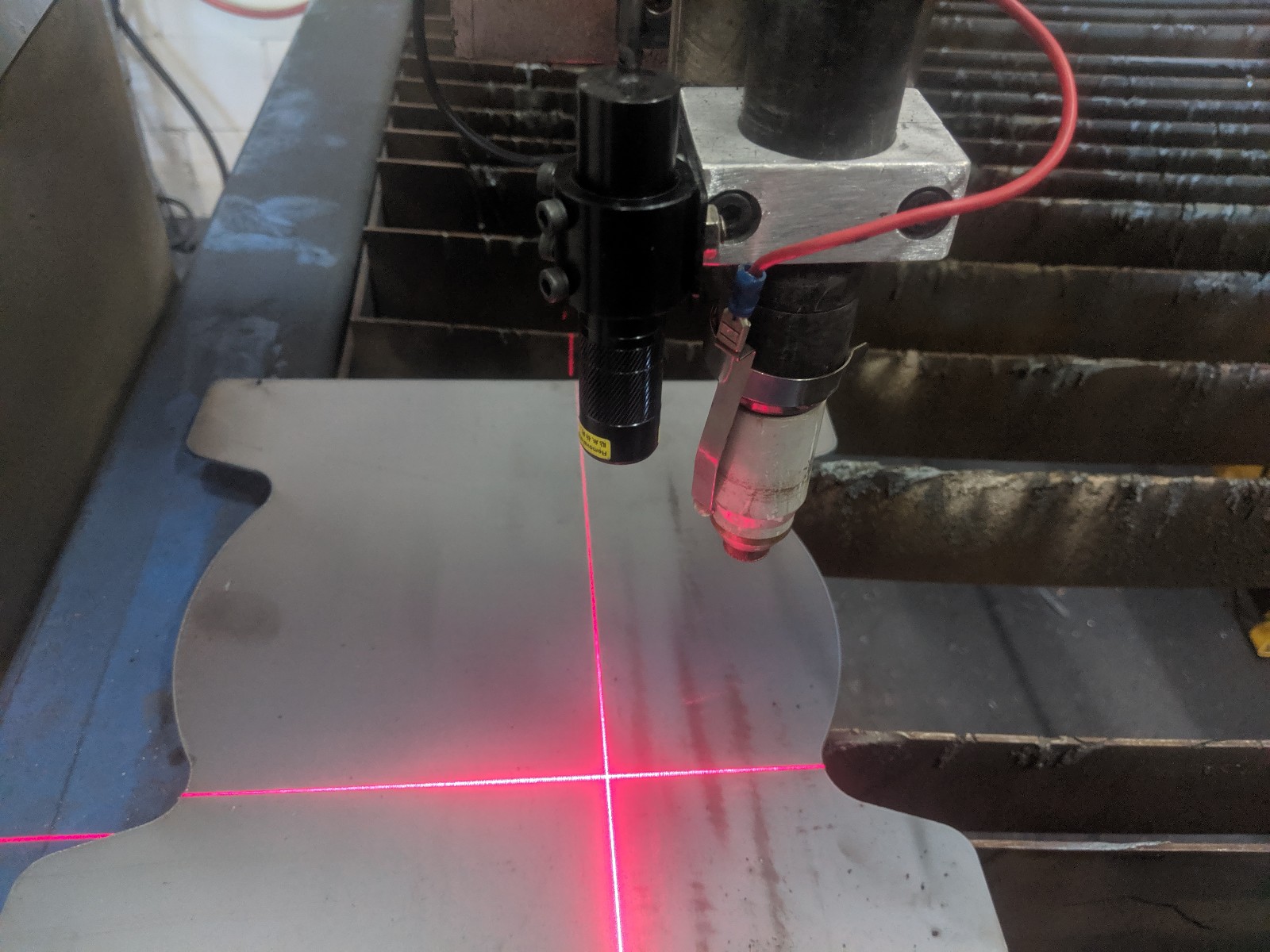

Anyway, in amongst a bit of business related Python programming, I managed to get this half installed on my table today.

I thought this laser pointer was a pretty good buy for $40. I had a tiny little one here that I had thought of fitting up but it was only a single dot and this one already had a mounting ring so it was real easy to fit using plasma cut plate screwed to the torch holder. I still have to wire this in to power. Unfortunately, the cables going up onto my gantry are all used, so I'm going to add a manual switch to turn this on. This is a 5 volt device and I purchased a small 24 volt to 5 v power supply which should fit into the existing metal box on the gantry.

I know its mounted fairly low but I found it had to be mounted well away from the torch if it was any higher so I hope it works out OK over time..

It is pretty square, just the material I put down isn't! I found just tightening the 4 grubscrews that hold the laser tube twisted it off square.

So if anybody has any ideas on how to handle the offsets to use this, I would appreciate some pointers. I know what I have to do to calculate the offset and square it. but its the software stuff I'd like to know a bit more about.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

Several years ago on PS there was a guy that installed a switch on a pneumatic cylinder for probing. As I recall he had a couple of Gcode subroutines that he used for probing.

I would be inclined to just write a small MDI macro to do it since you are not probing. Move material or crosshairs to desired location then make an offset move to put the torch there.

I actually built mine with two laser line generators mounted 90 degree apart that cross under the torch. I use clear packing tape for a window to protect the lasers, it lasts about a month and then I put on a new piece.

John

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21370

- Thank you received: 7288

I had an Audi Quattro, sold it some 5 years ago ( more like donated it to a friend ), but I made it go faster by changing and uploading some software! These new cars with to much electronics took all the fun out of making them go faster! In my young days we had to yank the engine out, disassemble it totally, change the head with one that had bigger valves, lower the head and block to the point that cylinders were nearly bumping on said valves, make 4>2>1 exhaust, but bigger nozzles on the carburetors etc etc etc. That was fun!

Also got one of those lasers with a cross but smaller one for 15 euro a while back, still in it's package waiting!

BTW, did you get the message? I got no confirmation for it!

Please Log in or Create an account to join the conversation.