Rods "Spaceship" Scratch built Plasma Cutter build

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

16 May 2019 20:00 #133997

by bevins

What is the POT for? Some kind of sensitivity circuit depending on the ohmic input?

Replied by bevins on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod,

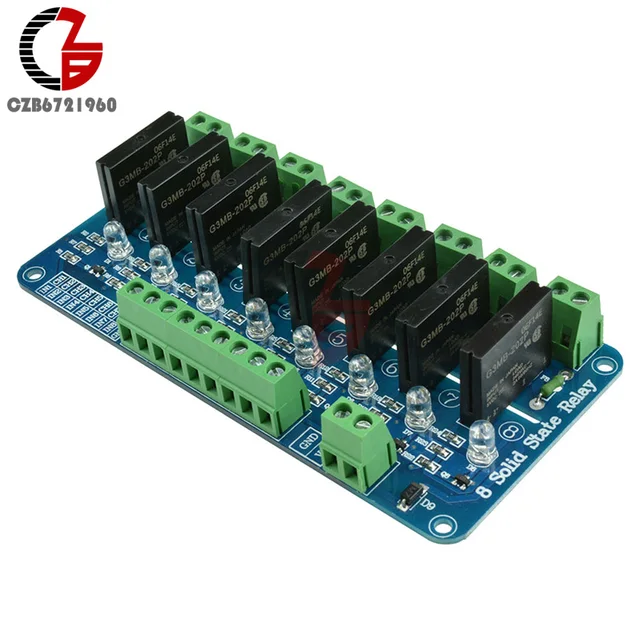

Thanks for the information and circuit drawing. I've been playing around with some ideas myself and have attached what I plan to use for the ohmic sensing circuit. Interestingly, I found some single chip SSRs ($2.16 each) that I think will work well for this project. I also have a circuit for ohmic sensing that will allow you to adjust the sensitivity so that less than optimal metal could be detected (maybe overkill and not needed). I'm using an optocoupler to send the final signal back to the control board as it has a much quicker response time (10uS) than the SSRs (0.3 - 1.0 mS). It's also probably overkill for the probing speeds that are used.

John,

Thanks for the information about the estop circuitry.

Steven

What is the POT for? Some kind of sensitivity circuit depending on the ohmic input?

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

16 May 2019 20:02 #133998

by bevins

Replied by bevins on topic Rods "Spaceship" Scratch built Plasma Cutter build

Nevermind, I just reread your post.... lol

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

16 May 2019 20:21 #134001

by rodw

Bevins, the RS Components part number for the relay was on the drawing. I used a Meanwell power supply that had a high isolation rating. The Power supply is totally seperate from field power and field power ground is not connected to the cabinet/table frame

John, thanks I'll look into it. I doubt its my wiring. The power supply has a plastic mounting clip so its not earthed to the rail. It will more likely be the power supply or dodgy wiring in a very old industrial shed. It was not insignificant at around 150 V AC

Steven, the relays I used are 50 uSec, way faster than the Servo thread requires. I would not over complicate things as its a proven design of Johns. I think some commercial tables do actually make it more complicated than what it needs to be as some have some sort of sensitivity adjustment. The other advantage of plasmac stemming from John's wisdom and experience is the test Ohmic sensor button. If the ohmic sense light comes on when you press this button (test before running a job), then you have a short inside the torch between shield and tip (happened once to me).

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Great work all on this plasmac. I cant wait to get to that point. Rodw, can you give me part numbers on your ohmic sensor?

Bevins, the RS Components part number for the relay was on the drawing. I used a Meanwell power supply that had a high isolation rating. The Power supply is totally seperate from field power and field power ground is not connected to the cabinet/table frame

John, thanks I'll look into it. I doubt its my wiring. The power supply has a plastic mounting clip so its not earthed to the rail. It will more likely be the power supply or dodgy wiring in a very old industrial shed. It was not insignificant at around 150 V AC

Steven, the relays I used are 50 uSec, way faster than the Servo thread requires. I would not over complicate things as its a proven design of Johns. I think some commercial tables do actually make it more complicated than what it needs to be as some have some sort of sensitivity adjustment. The other advantage of plasmac stemming from John's wisdom and experience is the test Ohmic sensor button. If the ohmic sense light comes on when you press this button (test before running a job), then you have a short inside the torch between shield and tip (happened once to me).

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

16 May 2019 21:15 #134007

by islander261

Replied by islander261 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod

Please have your electrical buddy help you find the source of this soon. I can think of several causes all of which are serious personnel/fire safety issues. I can give a bunch of guesses from here but this really needs someone there to check it out, consider hiring a licensed electrician if you buddy can't help, it is that serious.

John

Please have your electrical buddy help you find the source of this soon. I can think of several causes all of which are serious personnel/fire safety issues. I can give a bunch of guesses from here but this really needs someone there to check it out, consider hiring a licensed electrician if you buddy can't help, it is that serious.

John

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

16 May 2019 21:20 - 16 May 2019 21:32 #134008

by Grotius

Replied by Grotius on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hi Rod,

Thanks for the video. I have watched it for multiple times to see the details.

The visualistation of the torch height control is very nice. Probing goes a little slow. Speeding up the probe process is a to do item.

For info : in the EO branche the up and down speed is more violent with a sort of motor flow back control, like a servo that want to be back at position when it goes to far during violent probe speed. The parameter for this is ini.speed i think out of my head.

For your TD consumables set up, i have little suggeston Rod.

I prefer you to use a non shielded consumable solution. This option will provide you less slack polution at the end of torch when you are cutting a lot of pieces over time. At the moment you don't see solution when you are cutting a few pieces.

Deflector : 9-8243 is a non shielded option that can be used.

Thank you for deleting the Pon Catterpillar post. It's now order. They have ordered a GR_CNC with 200 Amps Thermal Dynamics driven by the most powerfull Linuxcnc.

Defeated Swiftcut and Microstep with linux.

My next mission in Belgium is to defeat a Italian Soitaab plc cnc plasma machine with windows embedded pre installed....

The machine works on a windows embedded plc with interfacing file's with usb or network only. Hmm.

Hmm.

Thanks for the video. I have watched it for multiple times to see the details.

The visualistation of the torch height control is very nice. Probing goes a little slow. Speeding up the probe process is a to do item.

For info : in the EO branche the up and down speed is more violent with a sort of motor flow back control, like a servo that want to be back at position when it goes to far during violent probe speed. The parameter for this is ini.speed i think out of my head.

For your TD consumables set up, i have little suggeston Rod.

I prefer you to use a non shielded consumable solution. This option will provide you less slack polution at the end of torch when you are cutting a lot of pieces over time. At the moment you don't see solution when you are cutting a few pieces.

Deflector : 9-8243 is a non shielded option that can be used.

Thank you for deleting the Pon Catterpillar post. It's now order. They have ordered a GR_CNC with 200 Amps Thermal Dynamics driven by the most powerfull Linuxcnc.

Defeated Swiftcut and Microstep with linux.

My next mission in Belgium is to defeat a Italian Soitaab plc cnc plasma machine with windows embedded pre installed....

The machine works on a windows embedded plc with interfacing file's with usb or network only.

Last edit: 16 May 2019 21:32 by Grotius.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- docwelch

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 25

16 May 2019 21:24 #134009

by docwelch

Replied by docwelch on topic Rods "Spaceship" Scratch built Plasma Cutter build

I hadn't actually considered the speed of the servo thread as a limiting factor but that's a great point. I was just thinking about the reaction speed of the circuit itself.

After seeing that people are successfully using a much simpler method of ohmic sensing, I may drop the extra circuitry. After all, why make this any more difficult than it has to be? Fortunately, I'm still in the planning stages and haven't sent off any boards to be made yet.

Steven

After seeing that people are successfully using a much simpler method of ohmic sensing, I may drop the extra circuitry. After all, why make this any more difficult than it has to be? Fortunately, I'm still in the planning stages and haven't sent off any boards to be made yet.

Steven

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

16 May 2019 21:41 #134012

by Grotius

Replied by Grotius on topic Rods "Spaceship" Scratch built Plasma Cutter build

@Steven,

I hadn't actually considered the speed of the servo thread as a limiting factor but that's a great point. I was just thinking about the reaction speed of the circuit itself.

For your board use "addf yourboard.read-all base-thread" and "addf yourboard.write-all base-thread".

For the components use in postgui : loadrt CustomTHC ...... addf CustomTHC servo-thread

You will see the most important is to add your custom board to the base-thread !

Think about the manhatten style. Use plug and play manhatten style connector's. Try to use a FPGA. Try to investegate if

you can switch from eternet to etercat protocol with the same FPGA. If so, you are good !!

I hadn't actually considered the speed of the servo thread as a limiting factor but that's a great point. I was just thinking about the reaction speed of the circuit itself.

For your board use "addf yourboard.read-all base-thread" and "addf yourboard.write-all base-thread".

For the components use in postgui : loadrt CustomTHC ...... addf CustomTHC servo-thread

You will see the most important is to add your custom board to the base-thread !

Think about the manhatten style. Use plug and play manhatten style connector's. Try to use a FPGA. Try to investegate if

you can switch from eternet to etercat protocol with the same FPGA. If so, you are good !!

Please Log in or Create an account to join the conversation.

- docwelch

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 25

16 May 2019 22:21 #134013

by docwelch

Replied by docwelch on topic Rods "Spaceship" Scratch built Plasma Cutter build

I’m planning on using a Mesa 7176e. I don’t think it would be worth my time/effort/aggravation to build that board for what it costs. I am just thinking of building a board with some SSRs - just something fun to do without too much stress.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

16 May 2019 22:35 - 16 May 2019 22:36 #134014

by Grotius

Replied by Grotius on topic Rods "Spaceship" Scratch built Plasma Cutter build

Last edit: 16 May 2019 22:36 by Grotius.

The following user(s) said Thank You: docwelch

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

17 May 2019 07:56 #134033

by rodw

Grotius, That wasn't me. But its great to have such a prestigious client. You will be driving that Lamborgini in no time!

Thanks for the ideas, yes I had the probing slow just becasue I had been playing with a few settings. I had been that slow normally. Also, I've never tuned plasmac and its a bit high when I measured it. I also noticed in the halscope plot i did the other day that the voltage was also tracking above the set point so I'm open to suggestions on how to tune plasmac.

John, I'll revisit my estop circuit and the breakaway circuit. I may have actually done it as that was just a backup config stored on Google Drive I posted. And yes, I will check out the isolated power supply. Thanks for the methodology.

Docwelch. If you search the forum for "my 7i76e connection sheet" you will find an incredibly useful document that was done by Norbert. I think Grotius is comparing the 7i76e with ethercat hardware. For a manufacturer, I think he has to go with that technology as that what commercial customers are expecting to see. I'd love to have a play with an ethercat drive but really the 7i76e and THCAD board are a very powerful combination.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hi Rod,

Thank you for deleting the Pon Catterpillar post. It's now order. They have ordered a GR_CNC with 200 Amps Thermal Dynamics driven by the most powerfull Linuxcnc.

Defeated Swiftcut and Microstep with linux.

Grotius, That wasn't me. But its great to have such a prestigious client. You will be driving that Lamborgini in no time!

Thanks for the ideas, yes I had the probing slow just becasue I had been playing with a few settings. I had been that slow normally. Also, I've never tuned plasmac and its a bit high when I measured it. I also noticed in the halscope plot i did the other day that the voltage was also tracking above the set point so I'm open to suggestions on how to tune plasmac.

John, I'll revisit my estop circuit and the breakaway circuit. I may have actually done it as that was just a backup config stored on Google Drive I posted. And yes, I will check out the isolated power supply. Thanks for the methodology.

Docwelch. If you search the forum for "my 7i76e connection sheet" you will find an incredibly useful document that was done by Norbert. I think Grotius is comparing the 7i76e with ethercat hardware. For a manufacturer, I think he has to go with that technology as that what commercial customers are expecting to see. I'd love to have a play with an ethercat drive but really the 7i76e and THCAD board are a very powerful combination.

The following user(s) said Thank You: docwelch

Please Log in or Create an account to join the conversation.

Time to create page: 0.145 seconds