Rods "Spaceship" Scratch built Plasma Cutter build

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

17 Apr 2019 00:13 #131021

by islander261

Replied by islander261 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod

I think your neighbors machine uses HV/HF start like most industrial machines so yes he should have the local ground rod for the table. You may not need one depending on the amount of moisture in your slab and how well the rebar was bonded when it was poured. I don't need one because the rebar in my slab is welded together for good bonding and then has it's own stranded #4AWG copper wire connection to the buildings ground rods.

John

I think your neighbors machine uses HV/HF start like most industrial machines so yes he should have the local ground rod for the table. You may not need one depending on the amount of moisture in your slab and how well the rebar was bonded when it was poured. I don't need one because the rebar in my slab is welded together for good bonding and then has it's own stranded #4AWG copper wire connection to the buildings ground rods.

John

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Online

- Platinum Member

-

Less

More

- Posts: 11638

- Thank you received: 3917

17 Apr 2019 08:36 - 17 Apr 2019 08:37 #131047

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

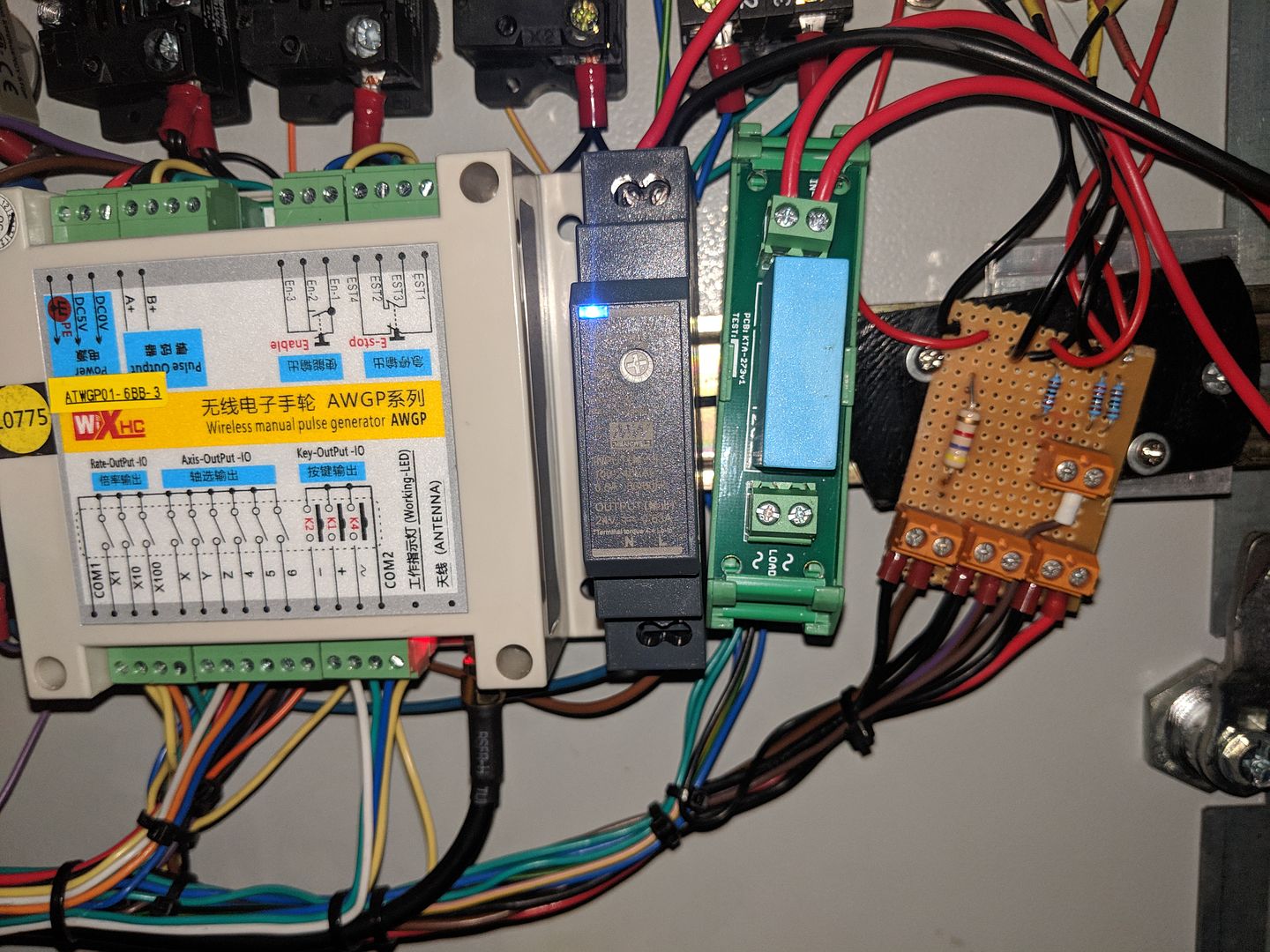

Well, I didn't get as much time today as I had hoped but I did get the Meanwell isolated 24 volt power supply (with the blue light) fitted so that mains power to it is dropped when estop is pushed.

The blue solid state relay is just sitting there for now but it is triggered when the torch shield touches the work piece. I've got two of these relays (for the Aussies, I sourced them and the power supplies from Ocean Controls).

I rigged this up on the table in a temporary way and hooked a 9 volt battery across the relay load terminals and was able to confirm everything worked as expected.

I figured that I need a couple of IN4007 1000 volt diodes to prevent the torch voltage being introduced into or circuit so I found a couple of terminal strips and soldered them on to a scrap of vero board. Then I remembered i had a current sensing board at home with a DIN rail mount so before I cut the vero board down, I decided to see if I could mount it in the DIN rail mount. five minutes later, I had it all fitted up nice.

The relays don't have any LED indicators on them, so I think I might add a bit more circuitry to this board for some diagnostics.

This looks so neat, I gotta do the same with the other dodgy circuit board that drives my LED power indicator lights. At the beginning of my build, a friend told me to add these for each power supply in the system for error checking and they saved a lot of time today. I inadvertently disconnected mains power the 48 volt power supply driving the steppers. I couldn't work out why I had problems until I check my power diagnostics LEDs and I instantly knew what I had stuffed up!

Hopefully, I'll have most stuff mounted up and working tomorrow.

The blue solid state relay is just sitting there for now but it is triggered when the torch shield touches the work piece. I've got two of these relays (for the Aussies, I sourced them and the power supplies from Ocean Controls).

I rigged this up on the table in a temporary way and hooked a 9 volt battery across the relay load terminals and was able to confirm everything worked as expected.

I figured that I need a couple of IN4007 1000 volt diodes to prevent the torch voltage being introduced into or circuit so I found a couple of terminal strips and soldered them on to a scrap of vero board. Then I remembered i had a current sensing board at home with a DIN rail mount so before I cut the vero board down, I decided to see if I could mount it in the DIN rail mount. five minutes later, I had it all fitted up nice.

The relays don't have any LED indicators on them, so I think I might add a bit more circuitry to this board for some diagnostics.

This looks so neat, I gotta do the same with the other dodgy circuit board that drives my LED power indicator lights. At the beginning of my build, a friend told me to add these for each power supply in the system for error checking and they saved a lot of time today. I inadvertently disconnected mains power the 48 volt power supply driving the steppers. I couldn't work out why I had problems until I check my power diagnostics LEDs and I instantly knew what I had stuffed up!

Hopefully, I'll have most stuff mounted up and working tomorrow.

Last edit: 17 Apr 2019 08:37 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Online

- Platinum Member

-

Less

More

- Posts: 11638

- Thank you received: 3917

18 Apr 2019 07:30 - 18 Apr 2019 07:31 #131114

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well I nearly have this done. Its taken a while which might be why I've been putting it off for ages.

So I've now got the power supply and the relays mounted up

I had a few issues and had some strange voltages floating around the table frame until I consulted my friend Chris who knows about these things so we just earthed the negative power rail of the isolated ohmic power supply to one of the copper posts inside the control panel and relied on contact between the table frame and the control panel where its bolted on.

Then I realised that the solid state relays I purchased were designed to switch AC only so when they triggered, they latched on as there was no zero crossing to turn them off. Grrr. I ordered some more but the company was out of stock so fell back to good old fashioned mechanical relays I had lying around!

So the left hand relay is connected to an output and it switches power from the isolated power supply to the ohmic sensor. When the torch touches the plate, it will trigger the right hand relay which will switch field power to an input for ohmic sensing.

So in practice, we enable an output to say we are probing which enables the ohmic sensing circuit. Then when the torch touches the plate, the signal will reach the ohmic input.

So with a bit of tidying up of the wiring, plasmac here we come!

But before we do, can someone educate me about flyback diodes/? I've heard I should use them to protect the Mesa inputs and outputs but not quite sure what I need to do.

So I've now got the power supply and the relays mounted up

I had a few issues and had some strange voltages floating around the table frame until I consulted my friend Chris who knows about these things so we just earthed the negative power rail of the isolated ohmic power supply to one of the copper posts inside the control panel and relied on contact between the table frame and the control panel where its bolted on.

Then I realised that the solid state relays I purchased were designed to switch AC only so when they triggered, they latched on as there was no zero crossing to turn them off. Grrr. I ordered some more but the company was out of stock so fell back to good old fashioned mechanical relays I had lying around!

So the left hand relay is connected to an output and it switches power from the isolated power supply to the ohmic sensor. When the torch touches the plate, it will trigger the right hand relay which will switch field power to an input for ohmic sensing.

So in practice, we enable an output to say we are probing which enables the ohmic sensing circuit. Then when the torch touches the plate, the signal will reach the ohmic input.

So with a bit of tidying up of the wiring, plasmac here we come!

But before we do, can someone educate me about flyback diodes/? I've heard I should use them to protect the Mesa inputs and outputs but not quite sure what I need to do.

Last edit: 18 Apr 2019 07:31 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

18 Apr 2019 08:00 #131119

by tommylight

Yea SSR have that nasty habit of remaining full on while DC current is passing through them !

Been putting of due to time constraints doing something with some big SCR ( 2 pieces of double 105A ), and lack of a decent idea of what to do with them! Thought of making a plasma power source but had 4 of them, now i am left with only 2 broken ones maybe it is time to recall that idea.

You just need to connect a diode ( made out of anode and cathode ) parallel to the relay coil. That is all there is to it, just mind the polarity, the diode side with the round mark goes to positive of the controlling output.

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Then I realised that the solid state relays I purchased were designed to switch AC only so when they triggered, they latched on as there was no zero crossing to turn them off. Grrr.

Yea SSR have that nasty habit of remaining full on while DC current is passing through them !

Been putting of due to time constraints doing something with some big SCR ( 2 pieces of double 105A ), and lack of a decent idea of what to do with them! Thought of making a plasma power source but had 4 of them, now i am left with only 2 broken ones maybe it is time to recall that idea.

Flyback diodes can not fly ! I have no clue why they are called that, but they are used to suppress any back EMF induced by switching inductive loads, and also protect against reverse voltage generated by motors.But before we do, can someone educate me about flyback diodes/? I've heard I should use them to protect the Mesa inputs and outputs but not quite sure what I need to do.

You just need to connect a diode ( made out of anode and cathode ) parallel to the relay coil. That is all there is to it, just mind the polarity, the diode side with the round mark goes to positive of the controlling output.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Online

- Platinum Member

-

Less

More

- Posts: 11638

- Thank you received: 3917

18 Apr 2019 08:44 #131126

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Thanks Tommy. I just had dinner and remembered I left a soldering iron on up at the shop so no red wine for me tonight. I better go and turn it off!

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

18 Apr 2019 08:54 #131132

by pl7i92

Replied by pl7i92 on topic Rods "Spaceship" Scratch built Plasma Cutter build

so i think i need to replace regulary the cable

the tables 4 Plasmas in shop are running almost the whole workday

so it is a matter of time to get them broken

the tables 4 Plasmas in shop are running almost the whole workday

so it is a matter of time to get them broken

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

19 Apr 2019 16:09 #131243

by tommylight

Replied by tommylight on topic Rods "Spaceship" Scratch built Plasma Cutter build

Done that many, many times !........ and remembered I left a soldering iron on up at the shop so no red wine for me tonight. I better go and turn it off!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Online

- Platinum Member

-

Less

More

- Posts: 11638

- Thank you received: 3917

22 Apr 2019 08:40 #131474

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well it too a while but I've finally added ohmic sensing and the plasmac config to my tale and I'm really excited how well plasmac works. It really is quite simple to install if you already have a working config as I described in this thread. forum.linuxcnc.org/plasma-laser/36410-in...her-plasma-component

I was doing it hand in hand with wiring in an ohmic sensing circuit which took a lot more effort than the new config.

So with plasmac all you need is a M3 S1 command and all of the touch off, torch voltage sampling ant THC just happens automatically. Anyway here is a video

I was doing it hand in hand with wiring in an ohmic sensing circuit which took a lot more effort than the new config.

So with plasmac all you need is a M3 S1 command and all of the touch off, torch voltage sampling ant THC just happens automatically. Anyway here is a video

The following user(s) said Thank You: phillc54, chimeno, tommylight, Grotius

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Apr 2019 10:08 #131476

by phillc54

Replied by phillc54 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod,

It's nice to see it doing some cutting.

I know you will like me less now but I am actually in Canberra.

Cheers, Phill.

It's nice to see it doing some cutting.

I know you will like me less now but I am actually in Canberra.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Online

- Platinum Member

-

Less

More

- Posts: 11638

- Thank you received: 3917

22 Apr 2019 10:32 #131482

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Sorry mate for getting the geography wrong. I was just checking you were watching it!

Funny that one of my best customers called to see me today on his way past which was nice. Dare I say it but he's from Canberra too!

Time is non existent for me. It took 2 months to finish the upgrades and I bought everything and made the drag chain support back then too! I really wanted the ohmic sensing working. I'll order some steel now and set up to cut 200 or so small parts similar to what I ws cutting which will save me a fairly expensive laser cutting job.

Funny that one of my best customers called to see me today on his way past which was nice. Dare I say it but he's from Canberra too!

Time is non existent for me. It took 2 months to finish the upgrades and I bought everything and made the drag chain support back then too! I really wanted the ohmic sensing working. I'll order some steel now and set up to cut 200 or so small parts similar to what I ws cutting which will save me a fairly expensive laser cutting job.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Time to create page: 0.211 seconds