Another plasma component...

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3932

29 Sep 2019 08:31 #146545

by rodw

I've got some plans I could sell you

Replied by rodw on topic Another plasma component...

Sorry Phill, I was just excited to show of how well it worked.

If it is any consolation it scribed and cut out in under 10 minutes, should be a quick task to check off.

I'm glad the floating head worked out for you. Don't forget I will need to add the time making one of them to the 10 minutes...

I've got some plans I could sell you

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Sep 2019 08:33 #146546

by phillc54

HaHa, I just told the missus I didn't know how to make one...

Replied by phillc54 on topic Another plasma component...

I've got some plans I could sell you

HaHa, I just told the missus I didn't know how to make one...

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

29 Sep 2019 09:46 #146548

by Clive S

If you don't tell them in the first place you don't have a problem.

Replied by Clive S on topic Another plasma component...

I've got some plans I could sell you

HaHa, I just told the missus I didn't know how to make one...

If you don't tell them in the first place you don't have a problem.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

30 Sep 2019 01:21 - 30 Sep 2019 01:27 #146660

by phillc54

Replied by phillc54 on topic Another plasma component...

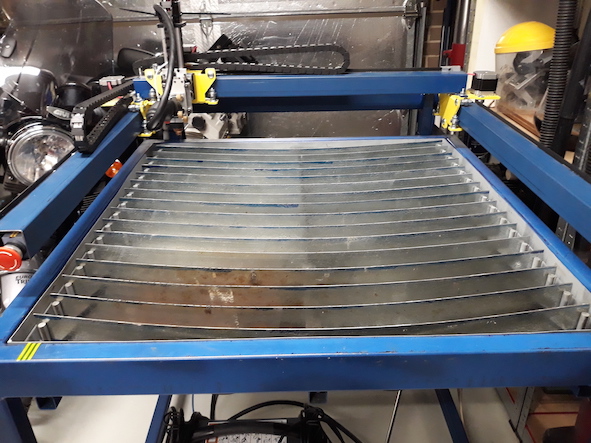

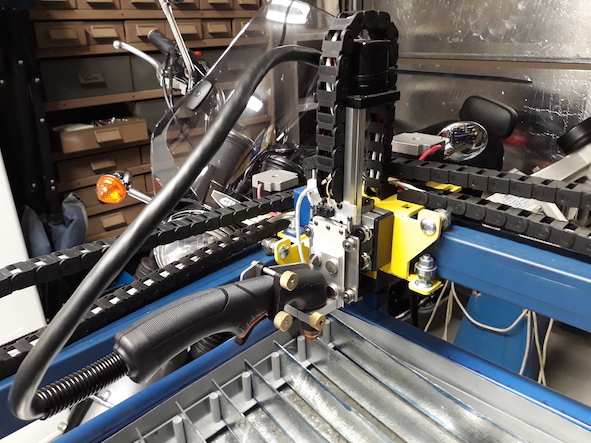

Some pics of the table. Excuse the cables drooping everywhere, like I said earlier there is a lot of tidying up to do.

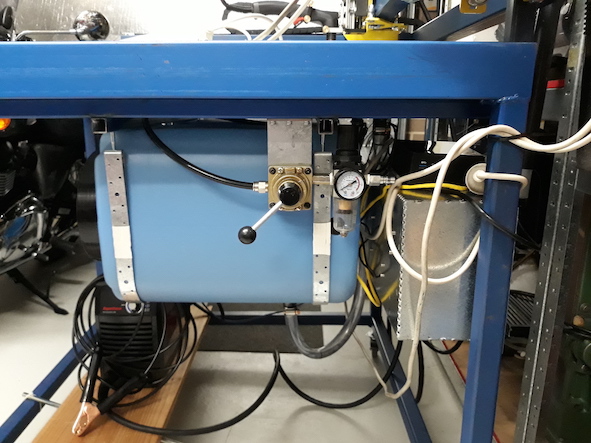

The two drums hold a total of 60 litres and the water is pumped up with air pressure and drains with gravity. As you can see I am pressed for room in the single vehicle garage. Cutting will be done outside so the table will be filled and drained for each session. It takes about 2 minutes to fill and about three to drain.

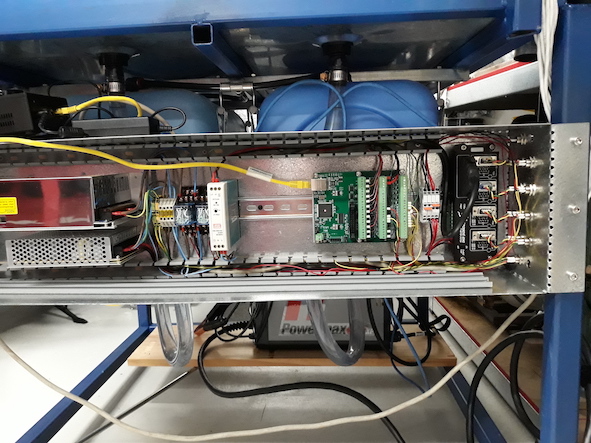

I have gone against the majority recommendation and directly wired the torch switch to the 7i96, it is only switching 18V and I have faith in PCW's design (plus a few spare inputs). So far so good.

The two drums hold a total of 60 litres and the water is pumped up with air pressure and drains with gravity. As you can see I am pressed for room in the single vehicle garage. Cutting will be done outside so the table will be filled and drained for each session. It takes about 2 minutes to fill and about three to drain.

I have gone against the majority recommendation and directly wired the torch switch to the 7i96, it is only switching 18V and I have faith in PCW's design (plus a few spare inputs). So far so good.

Attachments:

Last edit: 30 Sep 2019 01:27 by phillc54.

The following user(s) said Thank You: chimeno, Clive S

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

30 Sep 2019 07:21 #146687

by thefabricator03

Replied by thefabricator03 on topic Another plasma component...

Thats a tidy little table Phill,

I was going to go with a compressed air water height on mine but I changed my mind after making the first tank as I was worried that pressurizing a large steel tank could kill someone if any of the safety valves failed. I ended up with a 1000 l/m pump instead.

But on a smaller table it makes sense to use air pressure.

Is the table on castor wheels?

I was going to go with a compressed air water height on mine but I changed my mind after making the first tank as I was worried that pressurizing a large steel tank could kill someone if any of the safety valves failed. I ended up with a 1000 l/m pump instead.

But on a smaller table it makes sense to use air pressure.

Is the table on castor wheels?

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

30 Sep 2019 08:12 #146690

by phillc54

Replied by phillc54 on topic Another plasma component...

Yes, it is on castors.

The pressure for the water is only 1.5 - 2 bar.

The pressure for the water is only 1.5 - 2 bar.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

30 Sep 2019 08:19 #146691

by thefabricator03

Replied by thefabricator03 on topic Another plasma component...

My problem was I did not consider the safety factor of having a untested pressure vessel used in a workplace. Getting a tank 3000x1500x300mm tested is not cheap.

And a small amount of pressure over such a large area can cause problems. Especially if it were to pressurize up to our shop air pressure of 110 PSI.

But for a hobby machine is makes perfect sense. Especially when your the only one using it and you know what your doing.

And a small amount of pressure over such a large area can cause problems. Especially if it were to pressurize up to our shop air pressure of 110 PSI.

But for a hobby machine is makes perfect sense. Especially when your the only one using it and you know what your doing.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

30 Sep 2019 08:47 #146694

by phillc54

I will be the only one using it but I'm not sure that I know what I'm doing.

When I get the water to the correct level I unplug the air to be safe.

Replied by phillc54 on topic Another plasma component...

I can understand your concerns.But for a hobby machine is makes perfect sense. Especially when your the only one using it and you know what your doing.

I will be the only one using it but I'm not sure that I know what I'm doing.

When I get the water to the correct level I unplug the air to be safe.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

30 Sep 2019 09:09 - 30 Sep 2019 09:14 #146696

by thefabricator03

What was me when I first started using my machine. I had never use any other CNC machine before apart from my robots. When I first started cutting I did not have any cut settings fully sorted and I started cutting a 20mm plate for a job. I think I only got about 3 good parts out of that 3000x1500x20 sheet. A very expensive learning curve. Looking back I would of done things differently but I learnt a hell of a lot.

Replied by thefabricator03 on topic Another plasma component...

I will be the only one using it but I'm not sure that I know what I'm doing.

What was me when I first started using my machine. I had never use any other CNC machine before apart from my robots. When I first started cutting I did not have any cut settings fully sorted and I started cutting a 20mm plate for a job. I think I only got about 3 good parts out of that 3000x1500x20 sheet. A very expensive learning curve. Looking back I would of done things differently but I learnt a hell of a lot.

Last edit: 30 Sep 2019 09:14 by thefabricator03.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3932

30 Sep 2019 10:50 #146704

by rodw

Replied by rodw on topic Another plasma component...

Looks good Phill. I had a setback with my watertable as it had a leaking weld. I got as far as putting the tray in the back of the ute but had no time today to go and get the boys to reweld it (after all, I paid them to do it).

I've kinda half been looking for a tank of some kind but it needs to hold around 125 litres minimum.

I've kinda half been looking for a tank of some kind but it needs to hold around 125 litres minimum.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.238 seconds