Another plasma component...

- thefabricator03

-

- Visitor

-

After believing all the hype around CandCNC DTHC versions, I had version IV but they release version 5 soon after, I found it hard to believe that THC could be done cheaply but to a high standard. At the time a CandCNC DTHC IV was $500 USD for the card.

It just works, no two ways about it. I had problems with the CandCNC DTHC not working sometimes for no reason. That does not happen with the THCAD and PlasmaC.

I know I am preaching to the converted here but I do find it truly amazing how something so simple just works.

That is the reason I am working on developing LinuxCNC into a controller for my industrial robots. Once the development is done I will be able to cheaply monitor arc voltage while welding to track the positon of the weld seam keeping it on track. I priced the same system for one of my Motoman robots and it was $23,000AUD per robot.

Using LinuxCNC everyday on my plasma has confirmed its reliability if properly developed. I hope to one day have a open source config like Phills PlasmaC for industrial robots.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21211

- Thank you received: 7245

Due to exogenous circumstances i have not been able to test it on a machine, and i am reluctant to switch to it on client machines for two reasons, one is that the thc_toma config works perfectly and never ever fails so clients are very happy with it, and second it would require them to change the work flow. Also there is the issue of using SheetCam instead of Inkscape to get the full functionality out of PlasmaC.

In the words of Mr.Smith from "the Matrix", it is inevitable !!!

I am preparing parts and ordering stuff for 5 to 6 new plasma machines, from 1.1X0.6M to 6.5X2M with the fourth axis, it is terribly hard to get some parts here, and the worst part is i've spent the better part of last 3 months looking to outsource the metal work to some shops here and none of them are capable of making a straight, plum, correctly aligned metal construction. Lazy bastards !

My shop is to small at 80 sq.M. so it is already full, i can not extend it as soon it is going to be destroyed and new high rises built here, looking to find another place but nothing suitable so far, am completely broke from buying machine parts, have those said parts rusting and collecting dust in the shop, still waiting for some parts at that PET bottle factory, and i hate waiting, etc etc.

Still, i am healthy and so is my family, so frankly i do not give a rats a$$ about all that above, so in a moment of wisdom i am renting another shop thinking of opening a barber shop, of all things, so more running, less sleep, more challenges, more fun !

Please Log in or Create an account to join the conversation.

- KRAD-AT

-

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 1

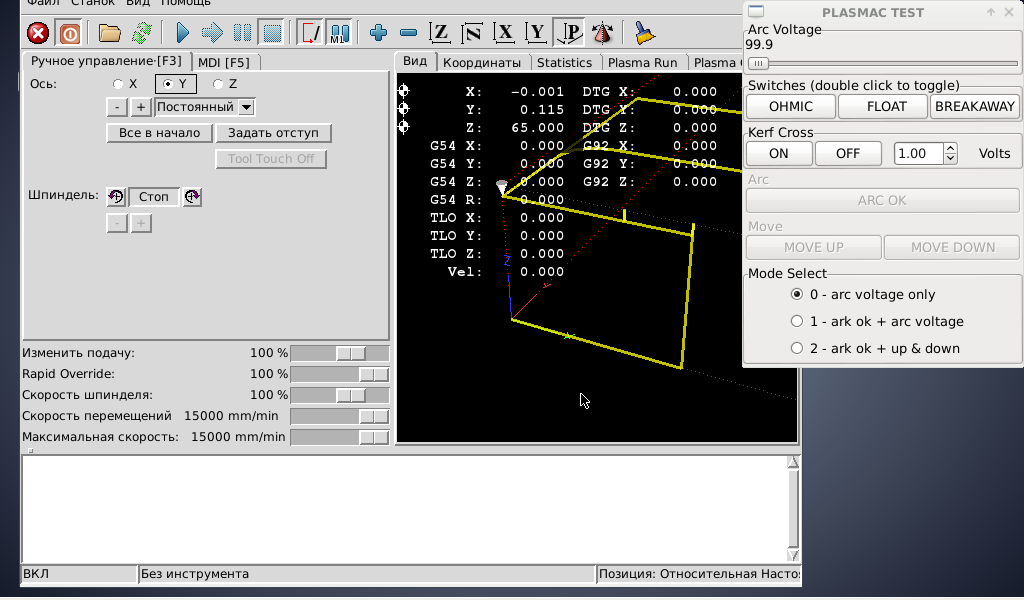

Today I made a new Config and upgraded to plasmac.

Most of all seem to work perfect.

One thing I recognizes is that continuous jogging does not work. Jogging in increments works fine.

The same thing as user sevaz saw in the post below.

Is there a solution already?

Cheers Martin

I tried but couldn't simulate the behaviour you described. PlasmaC has no control over jogging, that is done by Axis.Maybe i updated too early, so has caught some bugs. So i just deleted plasmac_axis.py and everything started to work like it should.

But of course i lost all cool axis tweaks.I am nor sure what you mean.

Ok, let me explain:

I set up a testing machine with a fresh new install of debian wheezy. Then I add wheezy repos(Master branch ) from buildbot.linuxcnc.org. After that I start Linuxcnc config picker from start menu.

Then i choose by machine > plasmac > metic axis;

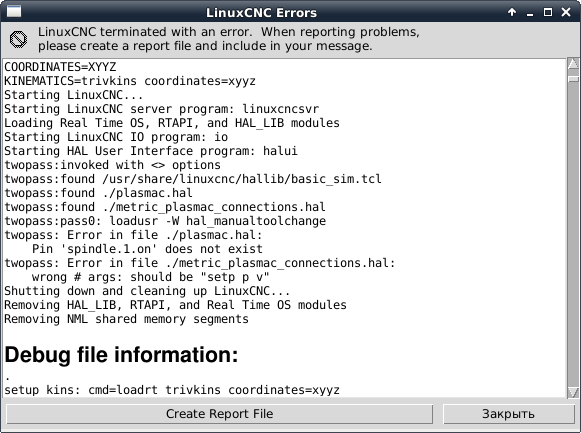

Then i try to start it and get following error message

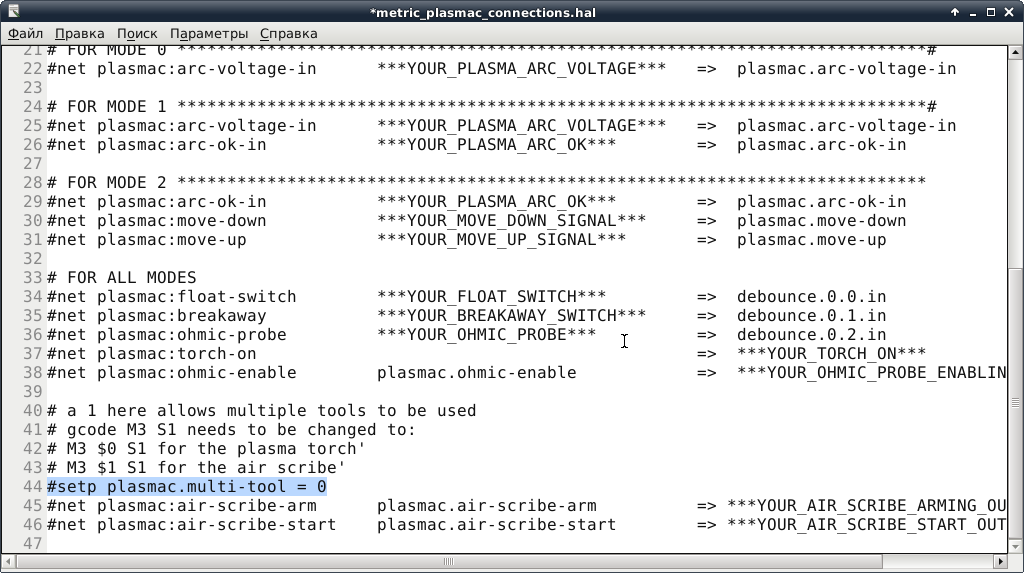

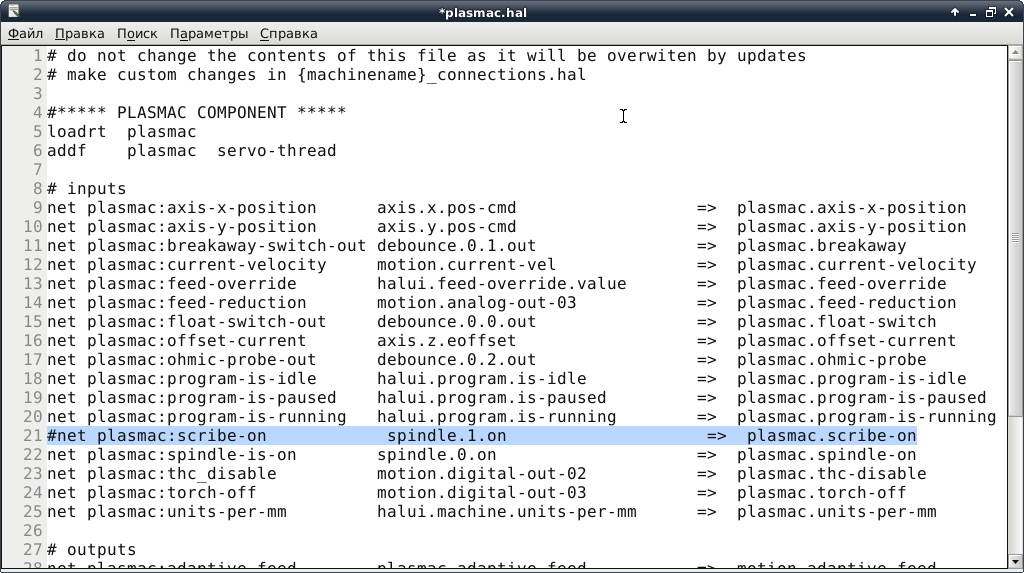

So I comment those lanes in both files:

In metric_plasmac_connections.hal

And in plasmac.hal

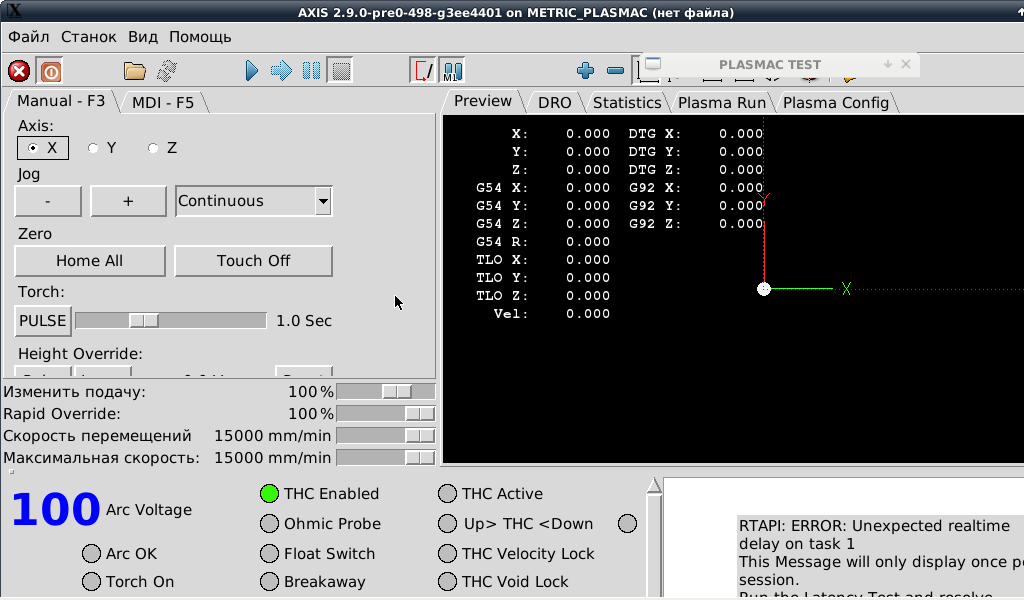

Only after that Axis starts and looks this way:

I installed debian on the old netbook, thus it has such a poor resolution, but the problem is the same on a working CNC.

So everything fine, except continuous jogging doesn't work at all. Neither keyboard nor screen buttons - and +, but if I set incremental jogging for example 10mm it moves. Then choose continuous again - nothing

So i decided that this problem is somehow connected with the axis tweaks, because default axis behaves normally.

That's why I deleted file plasmac_axis.py and restarted linuxcnc:

Now I have working continuous jogging, but there are no PlasmaC signals at the bottom anymore.

I would like to say, that i tried PlasmaC on my home PC with Ubuntu 18.04 and everything worked just right, except the first error message.

I think it could somehow depend on the old versions of Tk libraries, but unfortunately my knowledge in programming is limited.

I hope I've managed to clarify the problem, maybe I am just doing everything wrong, but PlasmaC on version 2.8 produced some good quality cuts without any serious problems.

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 63

thanks

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

If you mean for THC in the Config Panel then P=10, I=0 and D=0 seems to work quite well.Hi, I have some troubles to tune the PID loop basically I have a big steady-state error, I know every system is different, but do you have some guide or initial numbers?

thanks

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Could you post your .ini and .hal files plus any error messages you get.KRAD_AT wrote: Hello Guys!

Today I made a new Config and upgraded to plasmac.

Most of all seem to work perfect.

One thing I recognizes is that continuous jogging does not work. Jogging in increments works fine.

The same thing as user sevaz saw in the post below.

Is there a solution already?

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

- Posts: 197

- Thank you received: 63

Please Log in or Create an account to join the conversation.

- KRAD-AT

-

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 1

Thank you for your hard work on this project! You are great!

I attached my complete Config.

Cheers Martin

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- KRAD-AT

-

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 1

All I see is that jogging in increments (i.e 5mm) works, continuous doesn't.

Sorry I can't tell you more.

Please Log in or Create an account to join the conversation.