Another plasma component...

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

Ok, my advice is going to be contrary to others. The documents are correct.

1. The docs method of calculating the required offset and scale values does work. 1st, just use a 9V battery and your THCad card without the plasma CPC port connected. This will get your THCad card and display on the same page, the changes you will make going forward will be less than 2 orders of magnitude (powers of 10). The displayed voltage will be noisy. Look at the velocity output of the encoder component ( it will be noisy but will not change with changes to the scale or offset) while you are changing the offset and scaling values in the GUI. When you can get the displayed voltage to jump from 0 to the batteries voltage when you connect it you will be good, again this will be a little noisy.

2. I will assume you do not have a high voltage regulated power supply or don't want to mess with lethal voltages. Connect your THCad to your plasma power supply through the divided voltage on the CPC port. Connect a DVM with a 200VDC scale between your work piece and the torch electrode ( if you don't like this then put your DVM across the THCad input). Do a series of line cuts and record the voltage displayed on the gui and the voltage on the DVM If you have the DVM connected across the work piece and the torch electrode the ratio of the two voltages should be very close to the value that you need to adjust the scale to, it most likely will not be exact because of component tolerances. You will need to do this several times adjusting your offset and scale factors each time. You will get very close in the end. You can do all this by calculation (as I have done) and adjust the offset and scale to make the displayed value equal the measured value. Remember that you will need to change the offset value every time you change the scale value (check 0 between trials).

Sorry, I know this is clear as mud. If you can post the max and min values that came with your THCad we can at least get you within an order of magnitude of the correct offset and scale values.

I know this sounds crazy but having the perfect values really doesn't matter that much because you always want to do a series of line cuts to verify the book settings to your equipment anyway. I realize you run a job shop and need to be able to just plug in book cutting values to keep setup time to a minimum. This just means more time spent upfront getting your scaling and offset values close. You will still need to figure out a global offset between your measured cut values and the book ones. No one has made either measurement with the same calibrated equipment (unless you buy so much HT equipment they sent a rep to your shop).

John

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

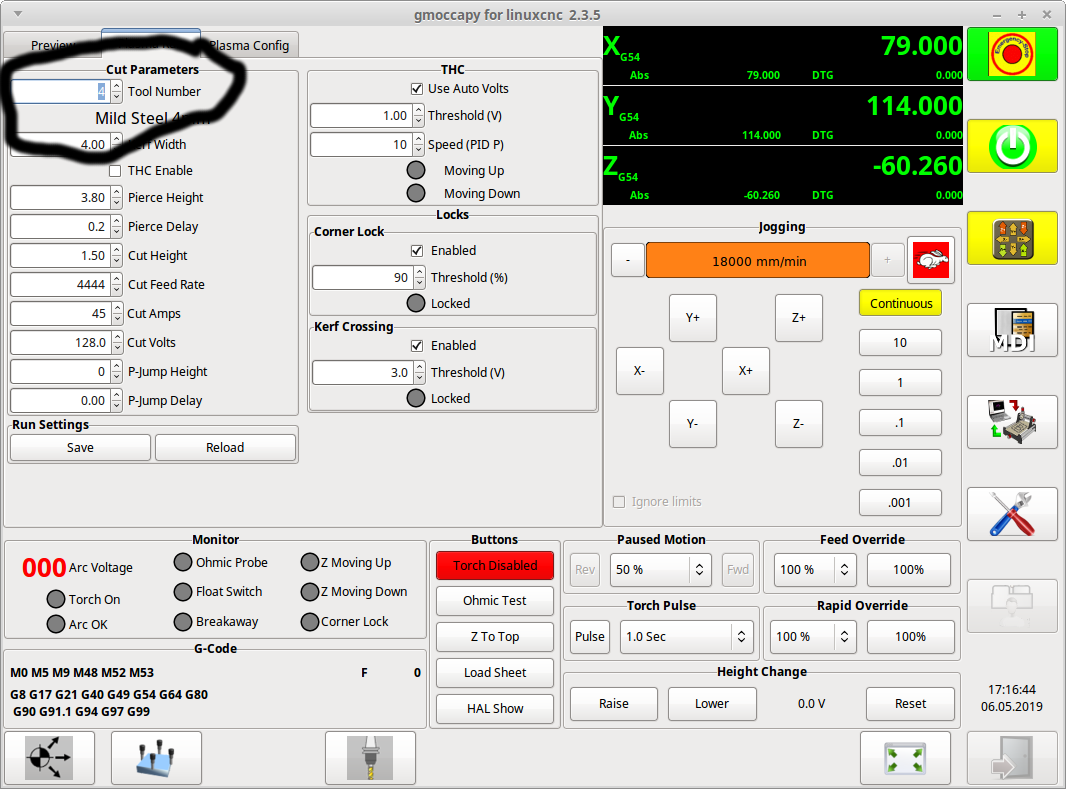

If you are using the plasmac gmoccapy config they are on the Plasma Config tab.In my machine.hal I don’t have arc-voltage-offset I have somthing listed as scale and filter. Where are you finding the actual arc voltage ofset settings? I did find settings in the mymachine_config.cfg file.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11729

- Thank you received: 3973

eg:

50:1 = 10 * 50 = 500 volts full sale -- 10/500 = 0.2

30:1 = 10 * 30 = 300 volts full scale -- 10/30 = 0.0333

16:1 = 10 * 16 = 160 volts full scale -- 10/16 = 0.0625

The only proviso is that the THCAD can sometimes see the resistor network on the CNC board as belonging to it (eg. Everlast). But the battery test will not identify the Everlast issue. The only way to do that is put say 100 volts through the divider and see what you get. ( I used 2 x 48 volt power supplies).

So I would just see on your first cut if the voltage is somwhere near the book settings. If its way out, you have a problem (like the Everlast). 03, I don't think your Hypertherm will give wrong results as my Thermal Dynamics did not.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I don't think it is that simple, we are actually using the scale to convert the velocity from the encoder to a voltage.50:1 = 10 * 50 = 500 volts full sale -- 10/500 = 0.2

30:1 = 10 * 30 = 300 volts full scale -- 10/30 = 0.0333

16:1 = 10 * 16 = 160 volts full scale -- 10/16 = 0.0625

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

You must have an older version, that was corrected recently.Lol there it is right there in broad daylight. I was searching through all the files lol. But now I have another problem, it will only take a max of 100 as an offset.

Or can change the lines in plasmac_config.py (around line 54) to:

self.builder.get_object('arc-voltage-offset').set_digits(1)

self.builder.get_object('arc-voltage-offset-adj').configure(0,-99999,99999,0.1,0,0)

self.builder.get_object('arc-voltage-scale').set_digits(6)

self.builder.get_object('arc-voltage-scale-adj').configure(1,-999,999,0.000001,0,0)Cheers, Phill.

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

git pull

make

sudo make setuidPlease Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Mostly (see below)Is it really as simple as

git pull

make

sudo make setuid

Unfortunately there isn't...I would rather just update to the current version but dont want to loose any of my work I put into my hal and ini files. Is there an easy way to update to current?

If you did it like John suggested and did all your connections in your machine hal rather than plasmac.hal then there should be no hal problems.

Just keep a copy of your original ini file and you can modify that with any differences in the new ini file.

You will soon be a hal file and ini file expert...

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11729

- Thank you received: 3973

Does glade allow you to display 2 fields in a dropdown eg. Tool number and name?

We seem to have given up a lot of usability when implementing the tool table. I know most languages I've used allow this. eg. revert to a drop down with tool number and name on the one line

So if you have 200 or so tools in the table, this will become fairly unwieldy as you'd need an index card beside you to choose the tool you want.

Attachments:

Please Log in or Create an account to join the conversation.