Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11616

- Thank you received: 3909

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11616

- Thank you received: 3909

AUTO:

To specify an automatic tool change use M190 Pn (n being the plasmac tool number).

Then on the next line use M66 P3 L3 Q1 this is a handshake to let gcode know that the plasmac tool parameters are valid for the next cut.

Any number of tool changes can be made in a file but only ONE for each cut.

So thinking post processors here, does plasmac return any error codes if a tool is not found or doe it just timeout?

Also I've never used M0/M1. Is a pause for M1 only executed if a M0 is given earlier?

Thinking about how to implement error checking in a post processor if a tool is not found. If the M66 times out, -1 will be placed in #5399 so wanted to check it and pause if not found.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11616

- Thank you received: 3909

Thanks, I have something like this working OK

M190 P1 (Retrieve the tool on the Plasmac Plasma Controller)

M66 P3 L3 Q1 (Wait for the Plasmac Plasma Controller to acknowledge the change)

o 101 if [#5399 EQ -1] (check to be sure tool is found on Plasmac Plasma Comtroller)

(MSG, ## ERROR: Tool not found on plasmac Plasma Controller)

M0 (enable M1 pause)

o 101 endif

M1 (Settings Check)

( ###########################)

(Paused: Check the Plasmac Plasma Controller Settings )

( Hit RUN to continue)

( ###########################)I found the one second timeout errored on tool #50 so I got a chance to test this.The message pops up and pauses the program. Increased the timeout to 2 seconds and it worked. Had me stumped while it worked on one and not the other.

Yes there is a bit of spurious code there. I've taken about 300 lines out of the post and I just have one spurious G1 on its own to find.

I have to move the error into a subroutine as having it hardcoded was resulting in duplicate numbering of the if statements which creates an error.

With this post a tool called "CentrePunch" is used for drilling operations to spot hole centres. Its just a matter of moving holes to a new layer and running a drill operation on that layer that uses that tool.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11616

- Thank you received: 3909

There will be multiple tools in use per sheetcam layers.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

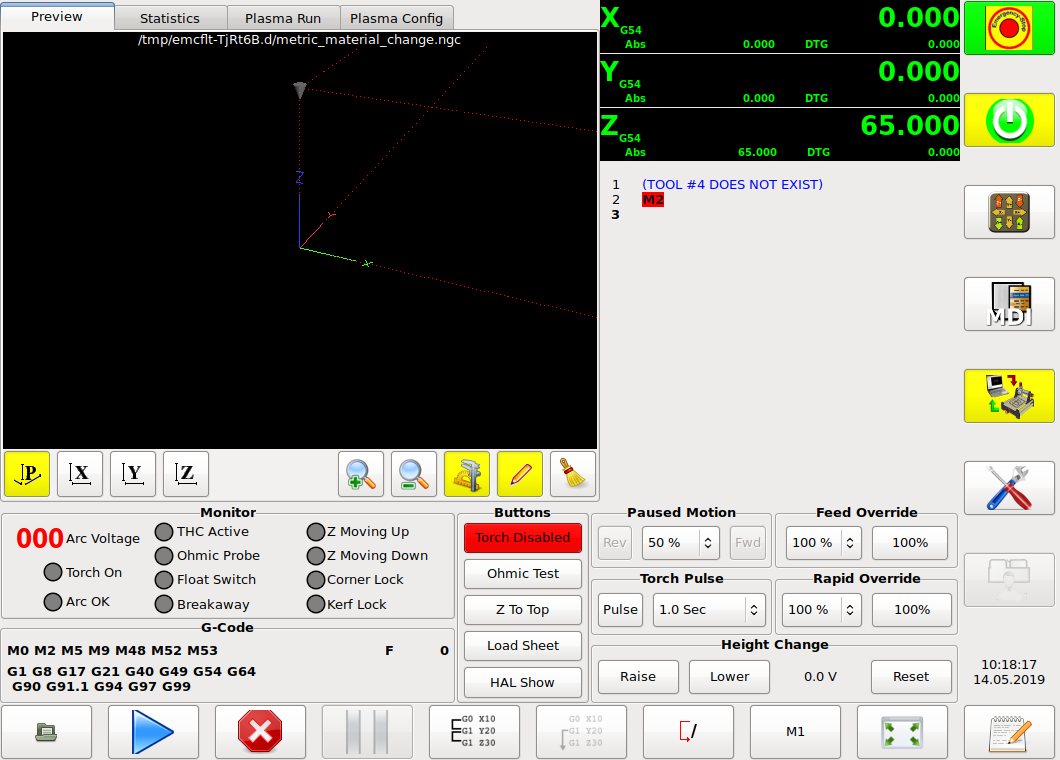

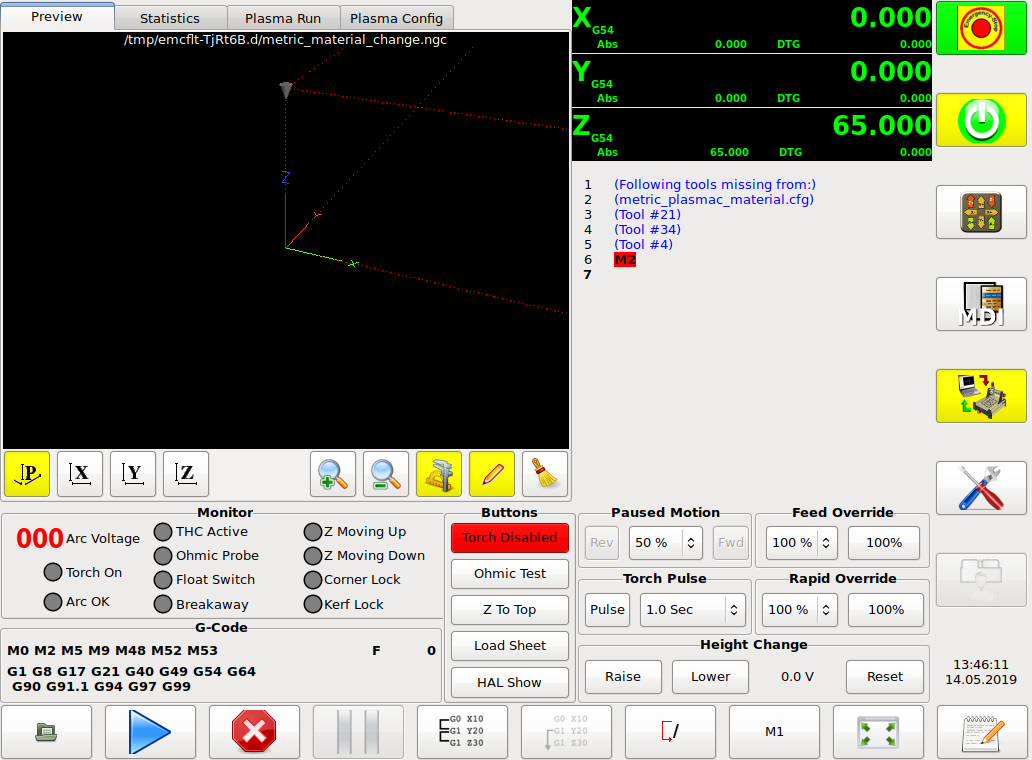

The gcode file is completely parsed before loading then it reports all tools that are not found and stops the program from loading.

It also makes for a cleaner gcode file as no code is required.

Cheers, Phill.

Edit: replace the plasmac_gcode.py in you config file with this one to give it a try. You shouldn't need to restart LinuxCNC.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

Thanks again for all your hard work. I cut 8 sheets out on Saturday and except for one apparent strange thing it all worked great! I am still using a version from the first week of May. Now here is what happened. I have a part the has a large number of simple pierces for holes close together (lots of dots) that are made with the THC disabled as they are typically cut (pierced, punched) with the same tool I use for open lines. For the most part this works really well with the IHS skip function really preventing nozzle damage and speeding things up. The only problem is if you have an error and you are within the IHS skip distance the machine doesn't reset to the "need to probe" state when come out of the machine paused condition. Of course this is one of those corner conditions that I am probably the only one to ever come across in routine use. I just wanted to report this before I forgot about it. This sheet has 18 parts on it with 1017 pierces on the sheet.

The Plasmac branch produces the best cut quality of any control I have used on my machine!

Rod

Thanks for helping everyone out with their configuration problems. I have been unemployed for nearly 4 years now and the arrival of new outside work (when I had just legally retired the day before) I don't have time to help out right now.

John

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

John thanks for the report, according to my docs it IS supposed to reset to the "need to probe" state.Phill

The only problem is if you have an error and you are within the IHS skip distance the machine doesn't reset to the "need to probe" state when come out of the machine paused condition. Of course this is one of those corner conditions that I am probably the only one to ever come across in routine use. I just wanted to report this before I forgot about it. This sheet has 18 parts on it with 1017 pierces on the sheet.

I will find out what I did wrong.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11616

- Thank you received: 3909

I think I prefer this way.

The gcode file is completely parsed before loading then it reports all tools that are not found and stops the program from loading.

It also makes for a cleaner gcode file as no code is required.

Cheers, Phill.

Phill, go with that then, I'm struggling with calls to the o code subroutine

o 100 sub

o 101 [if #5399 EQ -1] (check to be sure tool is found on Plasmac Plasma Comtroller)

(MSG, ERROR: Tool not found on Plasmac Plasma Controller)

M0 (enable M1 pause)

o 101 endif

o 100 endsub

.

.

.

o 100 callIm Getting an error "Unknown Control Command in O word in the call

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.