Another plasma component...

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

14 May 2019 07:50 - 14 May 2019 07:50 #133710

by rodw

Replied by rodw on topic Another plasma component...

I thought this was pretty interesting and just says how much wisdom there is in this open source group that is leading to such a superior plasma controller here in the LinuxCNC Plasmac hub!

I finally got a couple of prototype parts cut today. Its taken me 2 days mucking around with post processors and the inevitable plasmac upgrades twice a day! Anyway, I took them to my neighbour next door to get folded on his brake press. He purchased a $100k table about 6 months ago with a Hypertherm Maxpro 200 inverter with HF start on it. He's been plagued by intermittent problems when cutting mild steel.

They finally worked out this week that the high frequency start is causing noise or voltage to go back through the ohmic sensing circuit while cutting and causing the electronics to fault. As soon as they removed the ohmic sensor wire, it was fine. I guess it triggers an unexpected probe signal or similar which faults the system. I told him that that is not possible on my home built system the way the plasmmac/Islander ohmic sensing circuit is designed because both sides of the ohmic sensing circuit are physically disconnected unless we are actually probing.

This has been a very expensive fault for him in terms of downtime and also quite expensive for the supplier who have replaced a torch and electronics boards that are probably damaged. Instead of fixing it the plasmac way, they are stuffing around winding the ohmic wire around a bobbin to help prevent the RFI. They are actually going to reduce the wire diameter so they can get more turns around the bobbin! Sounds like a workaround for a poor design to me!

I finally got a couple of prototype parts cut today. Its taken me 2 days mucking around with post processors and the inevitable plasmac upgrades twice a day! Anyway, I took them to my neighbour next door to get folded on his brake press. He purchased a $100k table about 6 months ago with a Hypertherm Maxpro 200 inverter with HF start on it. He's been plagued by intermittent problems when cutting mild steel.

They finally worked out this week that the high frequency start is causing noise or voltage to go back through the ohmic sensing circuit while cutting and causing the electronics to fault. As soon as they removed the ohmic sensor wire, it was fine. I guess it triggers an unexpected probe signal or similar which faults the system. I told him that that is not possible on my home built system the way the plasmmac/Islander ohmic sensing circuit is designed because both sides of the ohmic sensing circuit are physically disconnected unless we are actually probing.

This has been a very expensive fault for him in terms of downtime and also quite expensive for the supplier who have replaced a torch and electronics boards that are probably damaged. Instead of fixing it the plasmac way, they are stuffing around winding the ohmic wire around a bobbin to help prevent the RFI. They are actually going to reduce the wire diameter so they can get more turns around the bobbin! Sounds like a workaround for a poor design to me!

Last edit: 14 May 2019 07:50 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 04:35 #133810

by rodw

Replied by rodw on topic Another plasma component...

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 04:56 #133812

by rodw

Replied by rodw on topic Another plasma component...

So now I am back at a desk I will add a few more comments. I will post a video video. I think you need to ignore ArcOK on a prolonged void crossing as I got a flameout when I tried to do that with a message about ArcOK being lost. Some machines have settings for expanded metal grates so maybe it can be left to run its course.

Also, I had some crap in the torch that shorted the ohmic sensor for the first time. The system went in an endless loop as soon as the torch started to probe and I had to kill LinuxCNC as I was flooded with errors about ohmic being on while probing. At least I learnt the purpose of the test button! If you press it and the light comes on with the torch in the air you have a problem that needs to be resolved.

Also, I had some crap in the torch that shorted the ohmic sensor for the first time. The system went in an endless loop as soon as the torch started to probe and I had to kill LinuxCNC as I was flooded with errors about ohmic being on while probing. At least I learnt the purpose of the test button! If you press it and the light comes on with the torch in the air you have a problem that needs to be resolved.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 05:04 #133813

by rodw

Replied by rodw on topic Another plasma component...

Phill, the biggest issue I've had with kerf crossing is on inside cuts causing a massive dive at the end of a cut as the slug falls away so I think you have fixed that. Should also allow corners to be looped. The other one is where you want to sever a sheet and just let it run off the edge of the plate when it dives badly. I think the insid cut quality will improve with this feature.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

15 May 2019 05:05 #133814

by phillc54

Replied by phillc54 on topic Another plasma component...

Rod,

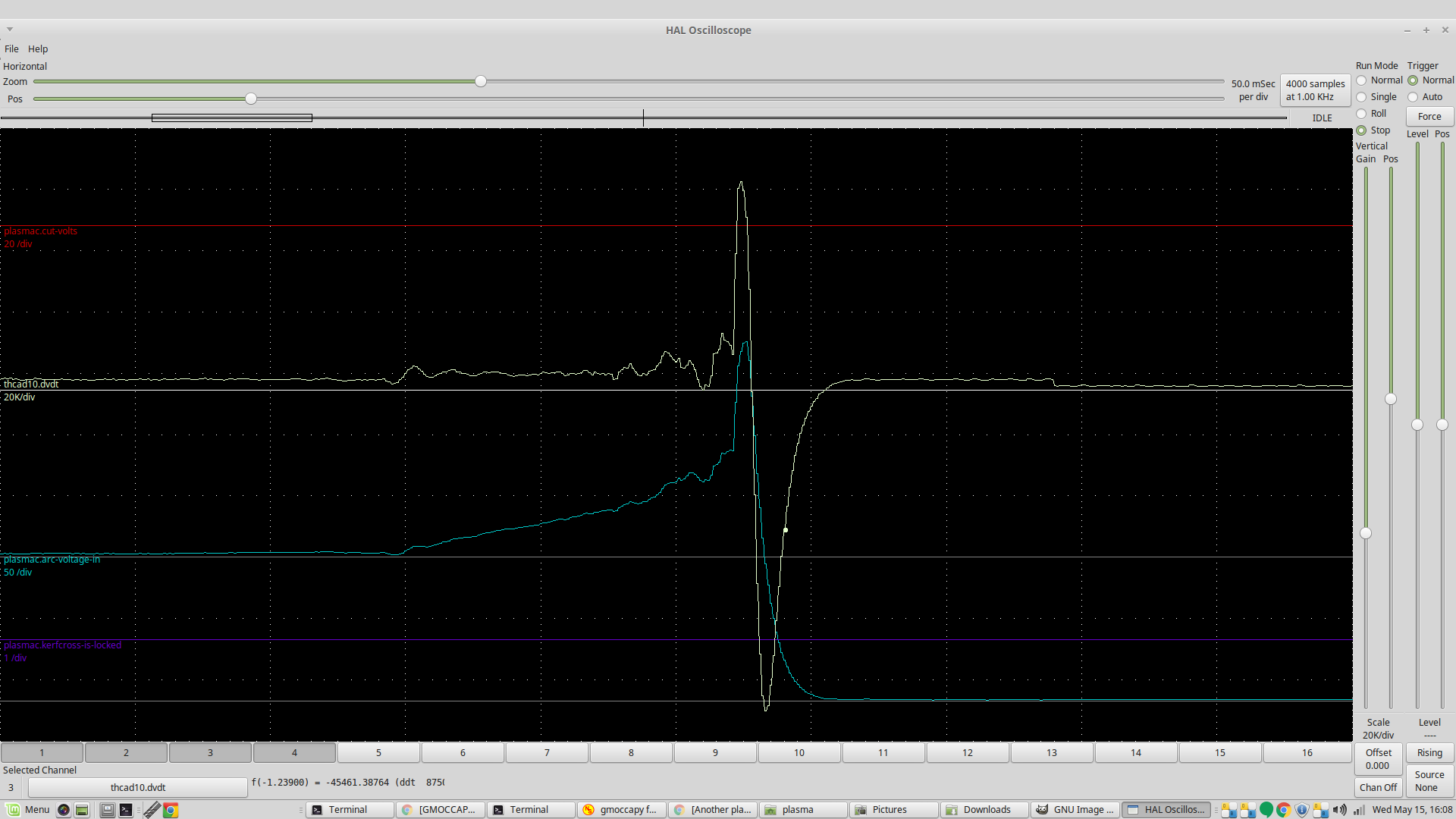

The way it displays at the moment is once plasmac.thc-active turns on it stays on for the duration of the cut.

plasmac.kerfcross-is-locked will turn on when it sees an over voltage and turns off when the voltage has returned to 'normal'

While plasmac.kerfcross-is-locked is on then thc is disabled so that is the pin to watch.

Cheers, Phill.

The way it displays at the moment is once plasmac.thc-active turns on it stays on for the duration of the cut.

plasmac.kerfcross-is-locked will turn on when it sees an over voltage and turns off when the voltage has returned to 'normal'

While plasmac.kerfcross-is-locked is on then thc is disabled so that is the pin to watch.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

15 May 2019 05:09 - 15 May 2019 05:10 #133815

by phillc54

Replied by phillc54 on topic Another plasma component...

Rod,

As long as you use F#<_hal[plasmac.cut-feed-rate]> for the feed rate cornerlock should work well as plasmac uses this feed rate for its cornerlock calculations.

Cheers, Phill.

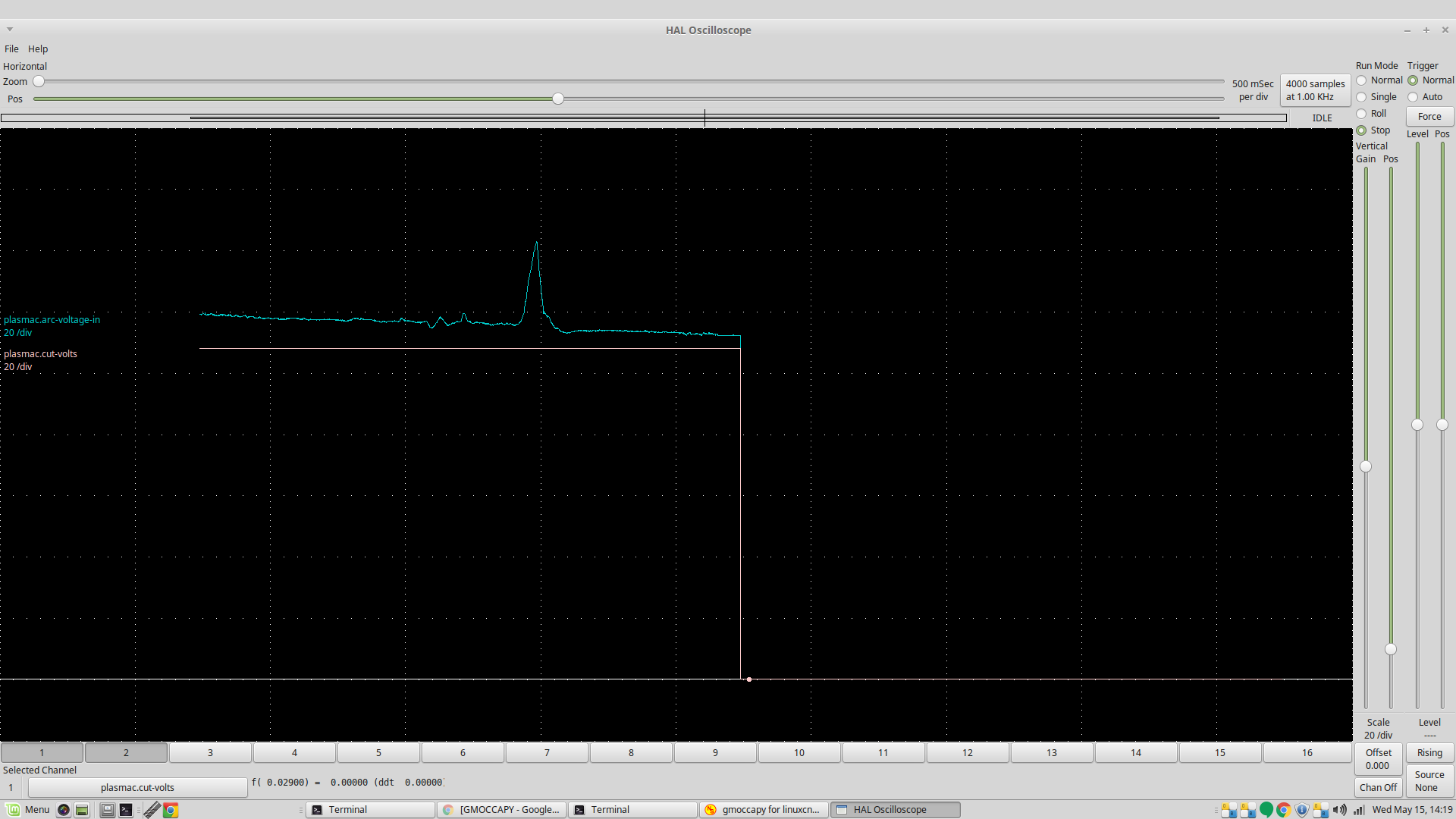

Edit: Do you use a lowpass on your arc voltage?

As long as you use F#<_hal[plasmac.cut-feed-rate]> for the feed rate cornerlock should work well as plasmac uses this feed rate for its cornerlock calculations.

Cheers, Phill.

Edit: Do you use a lowpass on your arc voltage?

Last edit: 15 May 2019 05:10 by phillc54.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 05:31 #133816

by rodw

Replied by rodw on topic Another plasma component...

Yes, I'm using the plasmac feedrate now I have a nice Sheetcam post processor!

I'll do some more plots when I get a chance. I found that opening halscope in Gmocappy actually saves the pins you connect.

No I don't. I included it in my scale THCAD component very early in the piece because PCW often suggests it. Dewey Garrett on the other hand did not recommend any filtering as it would interfere with PID response and that was my experience when I played. I still have my component installed to decode the torch volts so I think I might see if I can do a plot of dV/dT over your data to see if it could sense the void any quicker. Let me go and lok to see if I have a plot done in the past.

I'll do some more plots when I get a chance. I found that opening halscope in Gmocappy actually saves the pins you connect.

Edit: Do you use a lowpass on your arc voltage?

No I don't. I included it in my scale THCAD component very early in the piece because PCW often suggests it. Dewey Garrett on the other hand did not recommend any filtering as it would interfere with PID response and that was my experience when I played. I still have my component installed to decode the torch volts so I think I might see if I can do a plot of dV/dT over your data to see if it could sense the void any quicker. Let me go and lok to see if I have a plot done in the past.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 05:48 #133817

by rodw

Replied by rodw on topic Another plasma component...

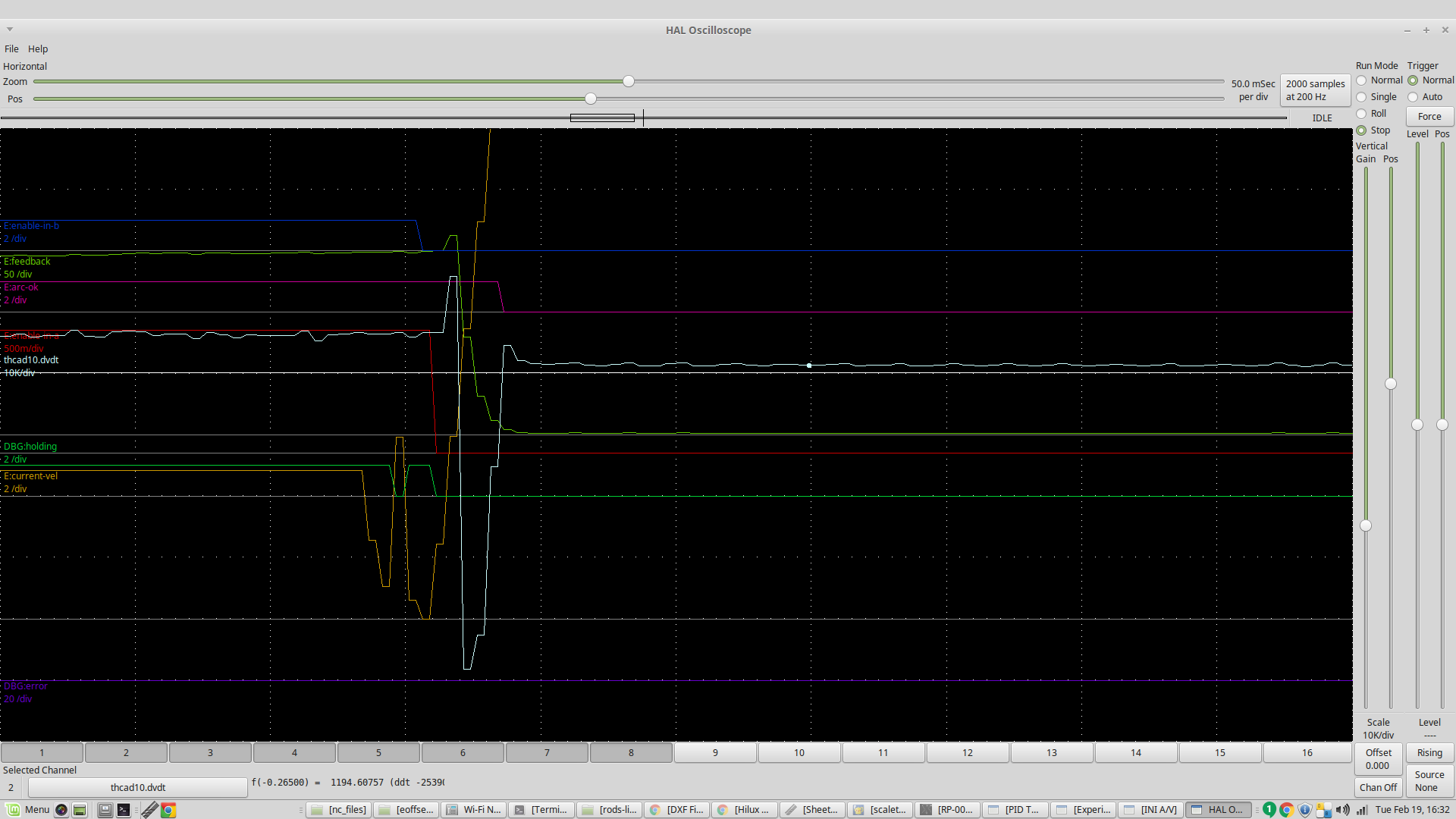

Phill, this is the only one I have showing dV/dT

It looks like it idles along at around 1200 volts/second (variation of about 1.2 volts per servo cycle on a stable cut) under normal cutting conditions and then spikes almost immediately to about 10,000

With Plasmac holding the THC, then it will be much easier to get some data

It looks like it idles along at around 1200 volts/second (variation of about 1.2 volts per servo cycle on a stable cut) under normal cutting conditions and then spikes almost immediately to about 10,000

With Plasmac holding the THC, then it will be much easier to get some data

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 06:15 - 15 May 2019 06:18 #133818

by rodw

Replied by rodw on topic Another plasma component...

Phil, On this plot it looks like your kerfcross-is-locked is true before we encounter the kerf and the voltage starts to rise. the dV/dT is idling along at about 3200 before the void. So holding the thc if it rises above 4-5000 would be a good threshold. The peak is up around 65000 v/sec

Anyway as usual, 1 cut will give a few days of thinking.... You really need to explore this in halscope as screen dumps only tell half the story as you can't rescale and explore as you can in halscope

Anyway as usual, 1 cut will give a few days of thinking.... You really need to explore this in halscope as screen dumps only tell half the story as you can't rescale and explore as you can in halscope

Last edit: 15 May 2019 06:18 by rodw.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

15 May 2019 06:25 #133819

by rodw

Replied by rodw on topic Another plasma component...

Attachments:

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.481 seconds