Valid Arc Lost, Thcad 300 config & Plasmac override

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

21 Mar 2020 17:23 #161003

by CNCFred

Valid Arc Lost, Thcad 300 config & Plasmac override was created by CNCFred

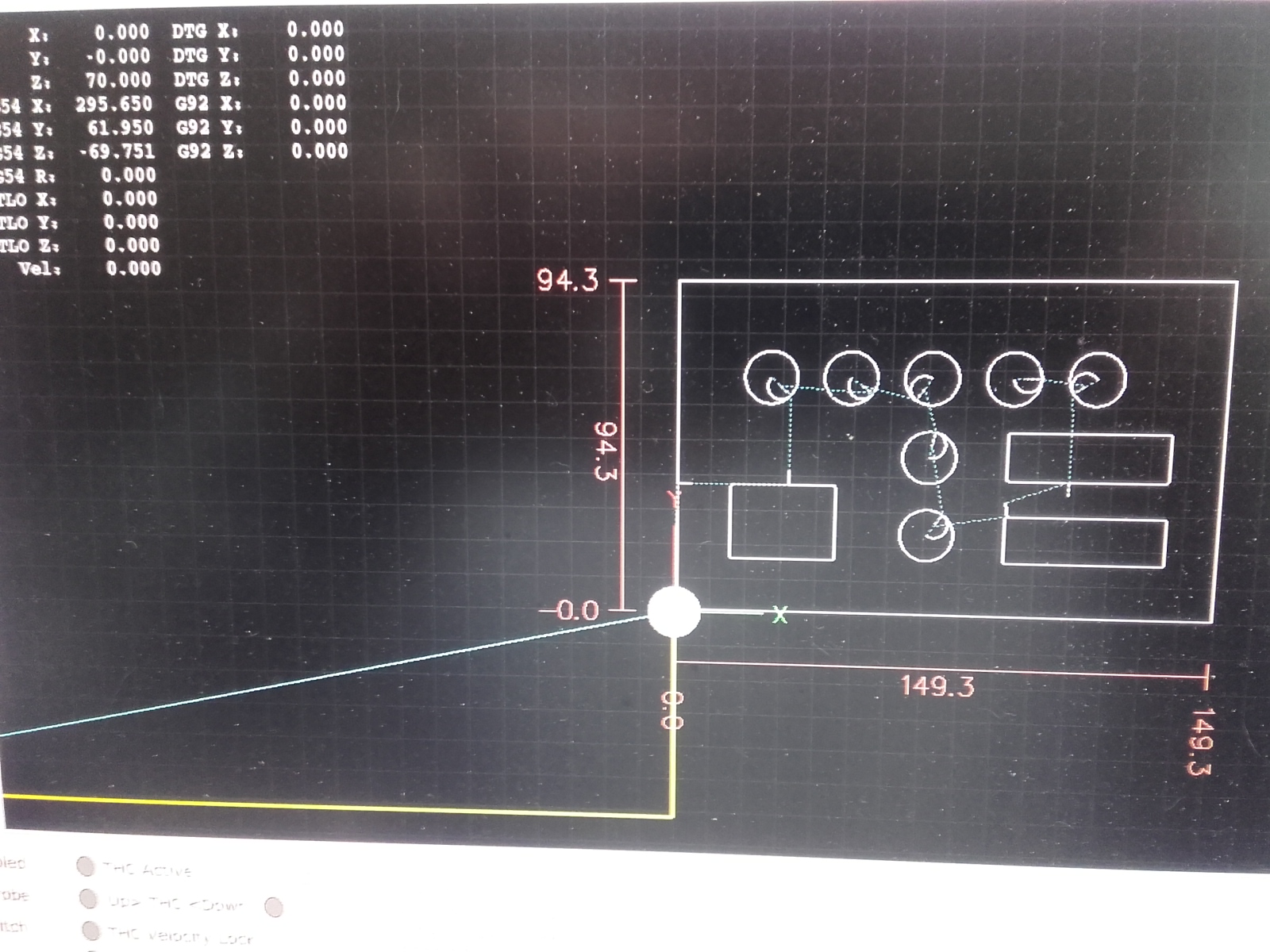

Finally I was able to make a gcode file with the plasmac post processor for fusion 360.

A:if I run the file without torch on , the torch works on probing like in the test probe (float travel seems to be ok, 1.5mm) but as soon as it starts to move (for circle etc.) it lowers Z and scratches on the surface.

there is no Z commands in my Gcode

B: the voltage showed -40V (offset the calculated one) so I set the offset to +40V the scale I entered the calculated scale.

When started I get the message Valid Arc Lost and the Z retracts up into the max limit.

If I set the scale to 1 it shows 0 volts but still only a view volts on startup.

C: if Z goes into the max limit how do you overwrite the limits in Plasmac screen, at the moment I turn the motor of and manually change the position.

0V Freq. 113.3Khz

300V Freq. 910.5kHz

calculated offset 3540.625

calculated scale 0.012042148

am I missing a setup in Plasmac?

thank you!!

A:if I run the file without torch on , the torch works on probing like in the test probe (float travel seems to be ok, 1.5mm) but as soon as it starts to move (for circle etc.) it lowers Z and scratches on the surface.

there is no Z commands in my Gcode

B: the voltage showed -40V (offset the calculated one) so I set the offset to +40V the scale I entered the calculated scale.

When started I get the message Valid Arc Lost and the Z retracts up into the max limit.

If I set the scale to 1 it shows 0 volts but still only a view volts on startup.

C: if Z goes into the max limit how do you overwrite the limits in Plasmac screen, at the moment I turn the motor of and manually change the position.

0V Freq. 113.3Khz

300V Freq. 910.5kHz

calculated offset 3540.625

calculated scale 0.012042148

am I missing a setup in Plasmac?

thank you!!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11620

- Thank you received: 3911

21 Mar 2020 20:27 #161026

by rodw

Replied by rodw on topic Valid Arc Lost, Thcad 300 config & Plasmac override

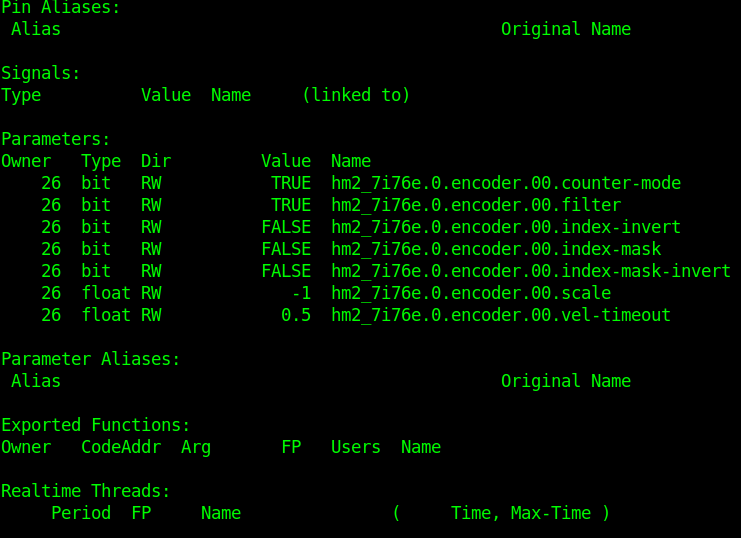

Fred, you need these lines in your hal file to make sure the voltage is positive. Check in Halshow for the correct encoder as my pin names may not be identical to yours. (the encoder scale corrects the voltage sign)

I think I know exactly why you are seeing 40 volts instead of around 90-120 volts but I am relying on my memory of you machine. I think that you have arc voltage connector pins on the back of your plasma cutter. Can you confirm that?

If that is so, I need you to grab a multimeter and measure the resistance between those pins and your arc leads. I expect it will be about 100 K Ohms on each pin if it is like other machines. They do this so the current on those pins won't kill you if you touch those pins.

So the problem is that the THCAD-300 contains scaling resistors to set that full scale reading to 300 volts. The THCAD is seeing the sum of the additional resistance on each voltage pin as part of those scaling resistors so you have set the full scale to maybe 900 volts or something like that. This means the scale you are using is incorrect.

The simple fix right now would be to multiply the scale factor you are using by a factor of 3 but if you quote the measured resistance, we should be able to come up with a more precise multiplier.

# --- 7i76e ENCODER SETUP FOR TORCH VOLTAGE ---

setp hm2_7i76e.0.encoder.00.scale -1

setp hm2_7i76e.0.encoder.00.counter-mode 1I think I know exactly why you are seeing 40 volts instead of around 90-120 volts but I am relying on my memory of you machine. I think that you have arc voltage connector pins on the back of your plasma cutter. Can you confirm that?

If that is so, I need you to grab a multimeter and measure the resistance between those pins and your arc leads. I expect it will be about 100 K Ohms on each pin if it is like other machines. They do this so the current on those pins won't kill you if you touch those pins.

So the problem is that the THCAD-300 contains scaling resistors to set that full scale reading to 300 volts. The THCAD is seeing the sum of the additional resistance on each voltage pin as part of those scaling resistors so you have set the full scale to maybe 900 volts or something like that. This means the scale you are using is incorrect.

The simple fix right now would be to multiply the scale factor you are using by a factor of 3 but if you quote the measured resistance, we should be able to come up with a more precise multiplier.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11620

- Thank you received: 3911

21 Mar 2020 20:57 #161027

by rodw

Replied by rodw on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Ooops, I was wrong with my guess. Must have been someone else I was thinking of. I found your original post with photos of your machine internals and your CAD drawings!

We need to look further into the scaling issue. But first lets get the voltage in the right direction as I suggested and your axis set right.

With regards correcting the axis cordinate. that can be fixed just by doing a touch off to 0 at the minimum limit position. I do it a bit different. I go to the top most Z position and know my travel is 86mm so I touch off at that position and enter 86mm

We need to look further into the scaling issue. But first lets get the voltage in the right direction as I suggested and your axis set right.

With regards correcting the axis cordinate. that can be fixed just by doing a touch off to 0 at the minimum limit position. I do it a bit different. I go to the top most Z position and know my travel is 86mm so I touch off at that position and enter 86mm

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Mar 2020 10:03 - 22 Mar 2020 10:56 #161077

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

one problem I solved so the Z axes does not run into the max limit.

from top to bottom:

max limit sensor

- 2.5mm soft limit (max limit soft top)

- 5mm home position

seems after running a program and on some occasions it returns Z to top max.

On probe , which hight should it stay ? pierce, float ??

I did a touch off set the plasma torch just above the material and set touch off to 0.

drew a hole in plasmac extras and tried again. It still sits on the surface.

I don't know how to add a video to the forum. (would be 16MB in size)

concerning the voltage:

I have in my hal as from the manual

setp hm2_7i76e.0.encoder.00.scale -1

setp hm2_7i76e.0.encoder.00.filter 1

setp hm2_7i76e.0.encoder.00.counter-mode 1

You then need to note that the Arc Voltage HAL Pin entry in the PlasmaC Configurator will be:

I think this is my problem? I don't have that pin it seems.

hm2_7i76e.0.encoder.00.velocity

here is my hallcmd show all .

thanks to PCW for showing the console command to me

thank you all for your help!

from top to bottom:

max limit sensor

- 2.5mm soft limit (max limit soft top)

- 5mm home position

seems after running a program and on some occasions it returns Z to top max.

On probe , which hight should it stay ? pierce, float ??

I did a touch off set the plasma torch just above the material and set touch off to 0.

drew a hole in plasmac extras and tried again. It still sits on the surface.

I don't know how to add a video to the forum. (would be 16MB in size)

concerning the voltage:

I have in my hal as from the manual

setp hm2_7i76e.0.encoder.00.scale -1

setp hm2_7i76e.0.encoder.00.filter 1

setp hm2_7i76e.0.encoder.00.counter-mode 1

You then need to note that the Arc Voltage HAL Pin entry in the PlasmaC Configurator will be:

I think this is my problem? I don't have that pin it seems.

hm2_7i76e.0.encoder.00.velocity

here is my hallcmd show all .

thanks to PCW for showing the console command to me

thank you all for your help!

Last edit: 22 Mar 2020 10:56 by CNCFred.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Mar 2020 11:02 #161083

by phillc54

Replied by phillc54 on topic Valid Arc Lost, Thcad 300 config & Plasmac override

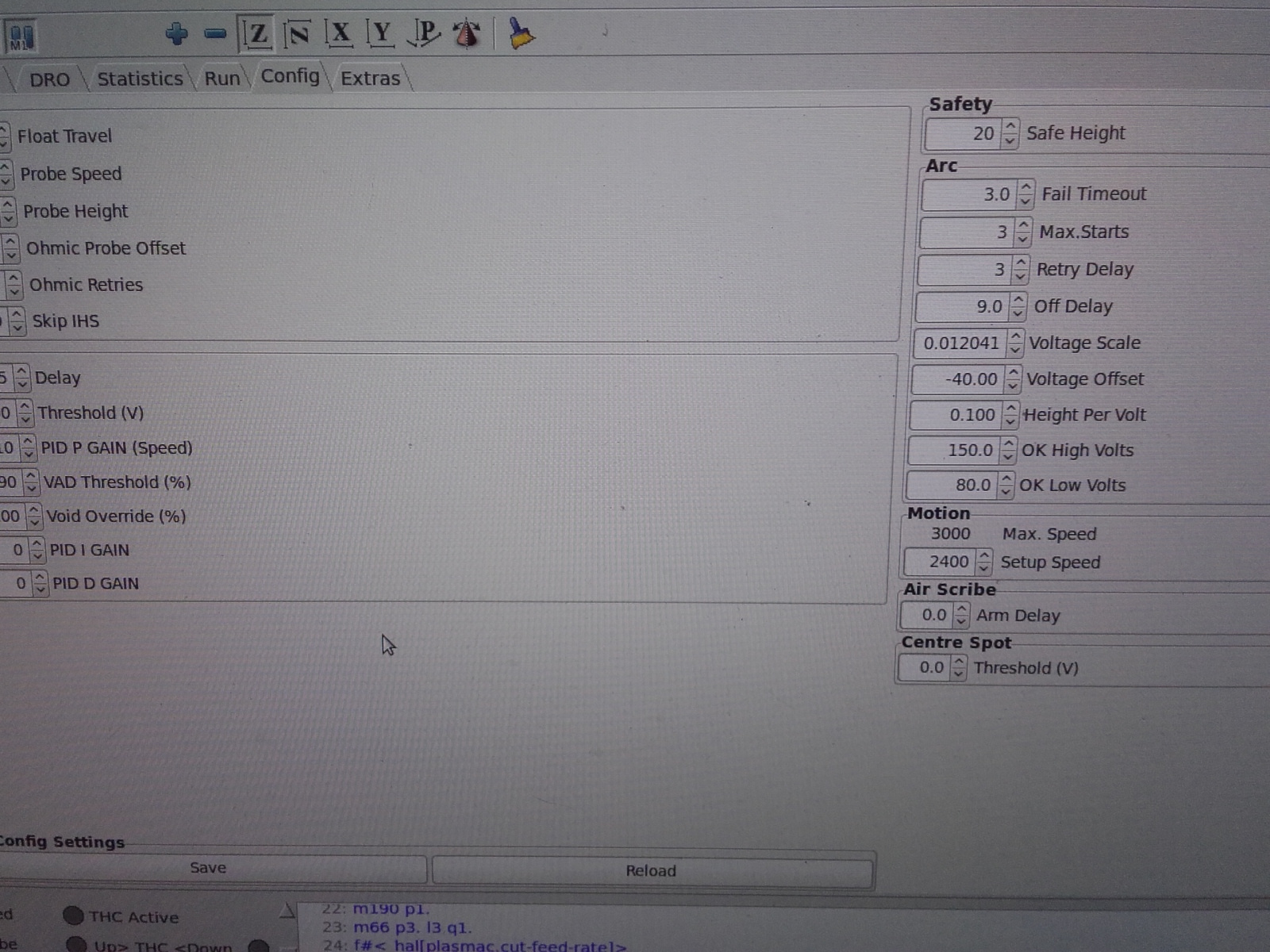

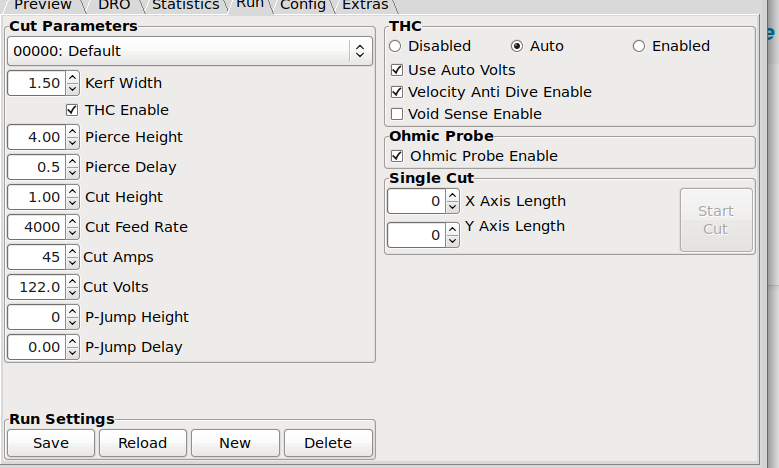

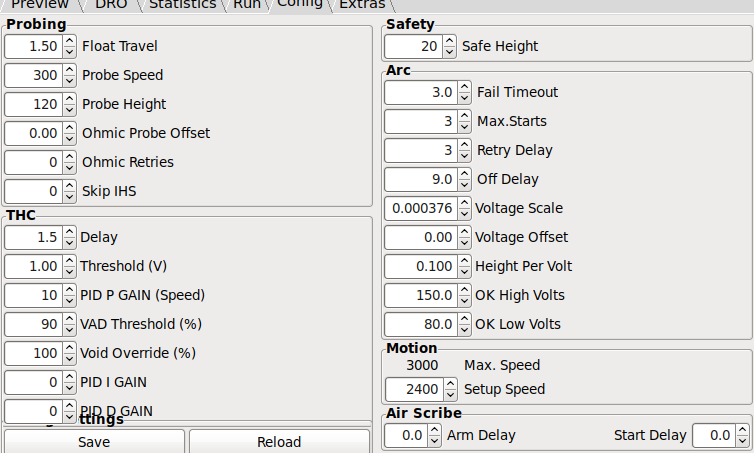

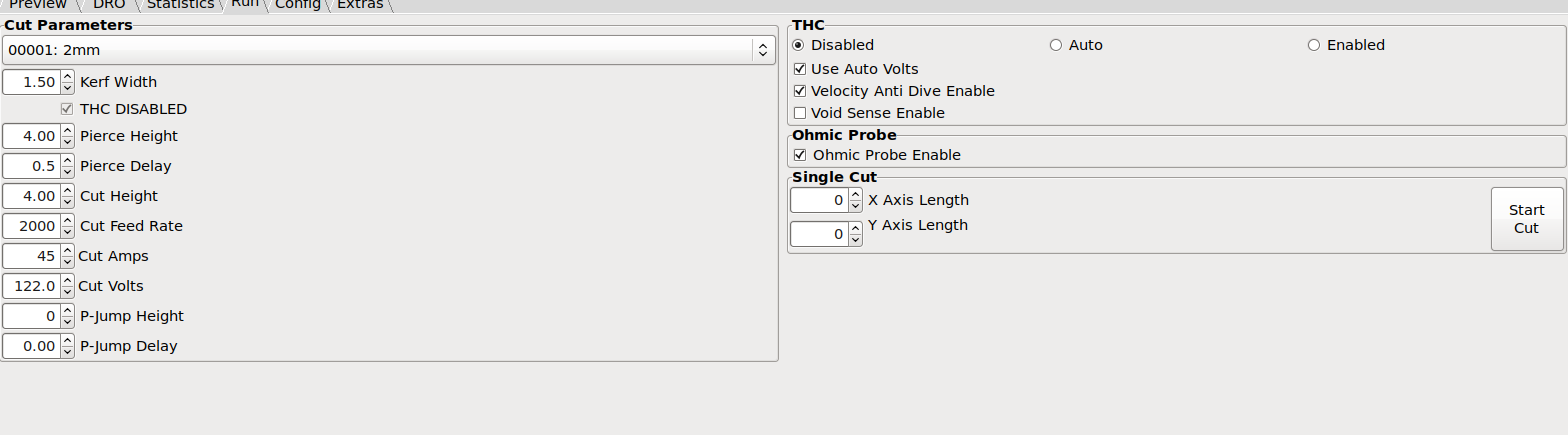

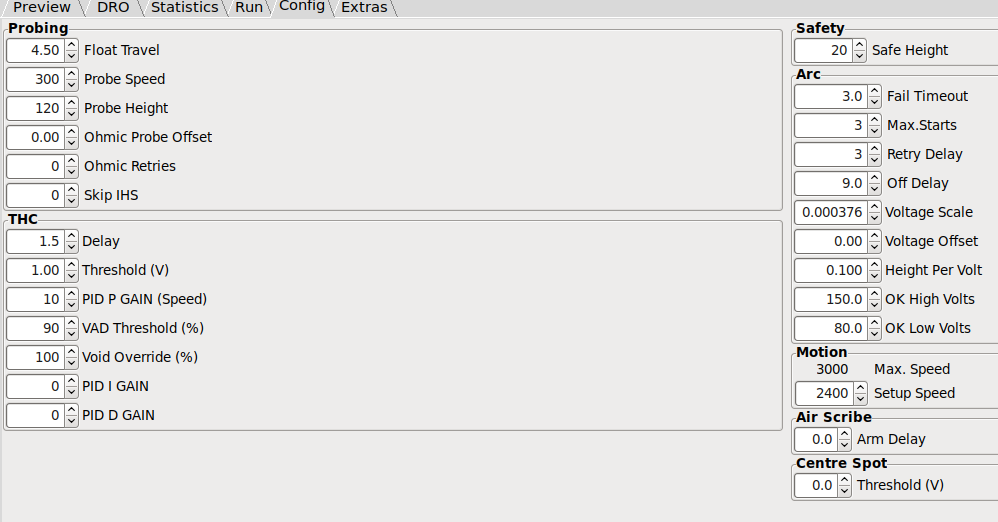

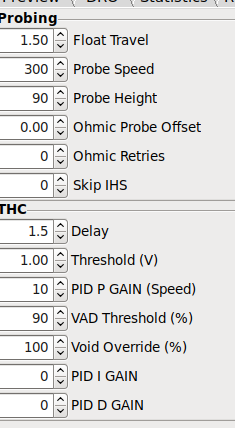

Could you post your .ini and .hal files and also a screenshot of the config panel.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Mar 2020 11:38 - 22 Mar 2020 11:44 #161086

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

here the ini and hal,

thank you...

thank you...

Last edit: 22 Mar 2020 11:44 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Mar 2020 13:03 - 22 Mar 2020 13:03 #161095

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Last edit: 22 Mar 2020 13:03 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Mar 2020 13:12 #161097

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

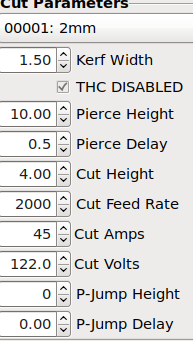

slowly I see , was wondering why no pierc height changed that as well much higher than cut height...

is doing it now..

something I am doing wrong...it seems, working so far, but should be different I guess...

touch off surface sheet metal,ok

probe , ok

then ....dives into material by 1mm or so...just scratching along...except I increase the cut height and pierce height...

thx...

is doing it now..

something I am doing wrong...it seems, working so far, but should be different I guess...

touch off surface sheet metal,ok

probe , ok

then ....dives into material by 1mm or so...just scratching along...except I increase the cut height and pierce height...

thx...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

22 Mar 2020 13:26 #161100

by tommylight

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Check if the scaling is correct for the Z axis, and also check the float travel.

Unselect "ohmic probe" if you do not have one.

Unselect "ohmic probe" if you do not have one.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

22 Mar 2020 13:46 #161104

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 3.831 seconds