Valid Arc Lost, Thcad 300 config & Plasmac override

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

23 Mar 2020 09:18 #161198

by rodw

Replied by rodw on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Try changing this

configs/plasmathc/plasmathc.hal: setp hm2_7i76e.0.encoder.00.scale -1

to:

configs/plasmathc/plasmathc.hal: setp hm2_7i76e.0.encoder.00.scale 1

That should give you positive volts. Then report back. the thing I have noticed is that the offset of 3540 = 41 volts if you multiply it by the voltage scale. So when you do that test cut, I want you to open hal show and watch hm2_7i76e.0.encoder.00.velocity becasue I don't think you are seeing a torch voltage from the THCAD. OR if you are, you are not sending it to PLasmac.

configs/plasmathc/plasmathc.hal: setp hm2_7i76e.0.encoder.00.scale -1

to:

configs/plasmathc/plasmathc.hal: setp hm2_7i76e.0.encoder.00.scale 1

That should give you positive volts. Then report back. the thing I have noticed is that the offset of 3540 = 41 volts if you multiply it by the voltage scale. So when you do that test cut, I want you to open hal show and watch hm2_7i76e.0.encoder.00.velocity becasue I don't think you are seeing a torch voltage from the THCAD. OR if you are, you are not sending it to PLasmac.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

23 Mar 2020 09:21 #161199

by rodw

Replied by rodw on topic Valid Arc Lost, Thcad 300 config & Plasmac override

And can you post your cad file/photo of your THCAD connections.

Can you then double check the physical wiring agrees with the diagram.

Can you then double check the physical wiring agrees with the diagram.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Mar 2020 12:50 - 23 Mar 2020 16:02 #161204

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

I am very sorry for wasting your time:

I checked the card which was in inside the plasma in a 3dprinted box.

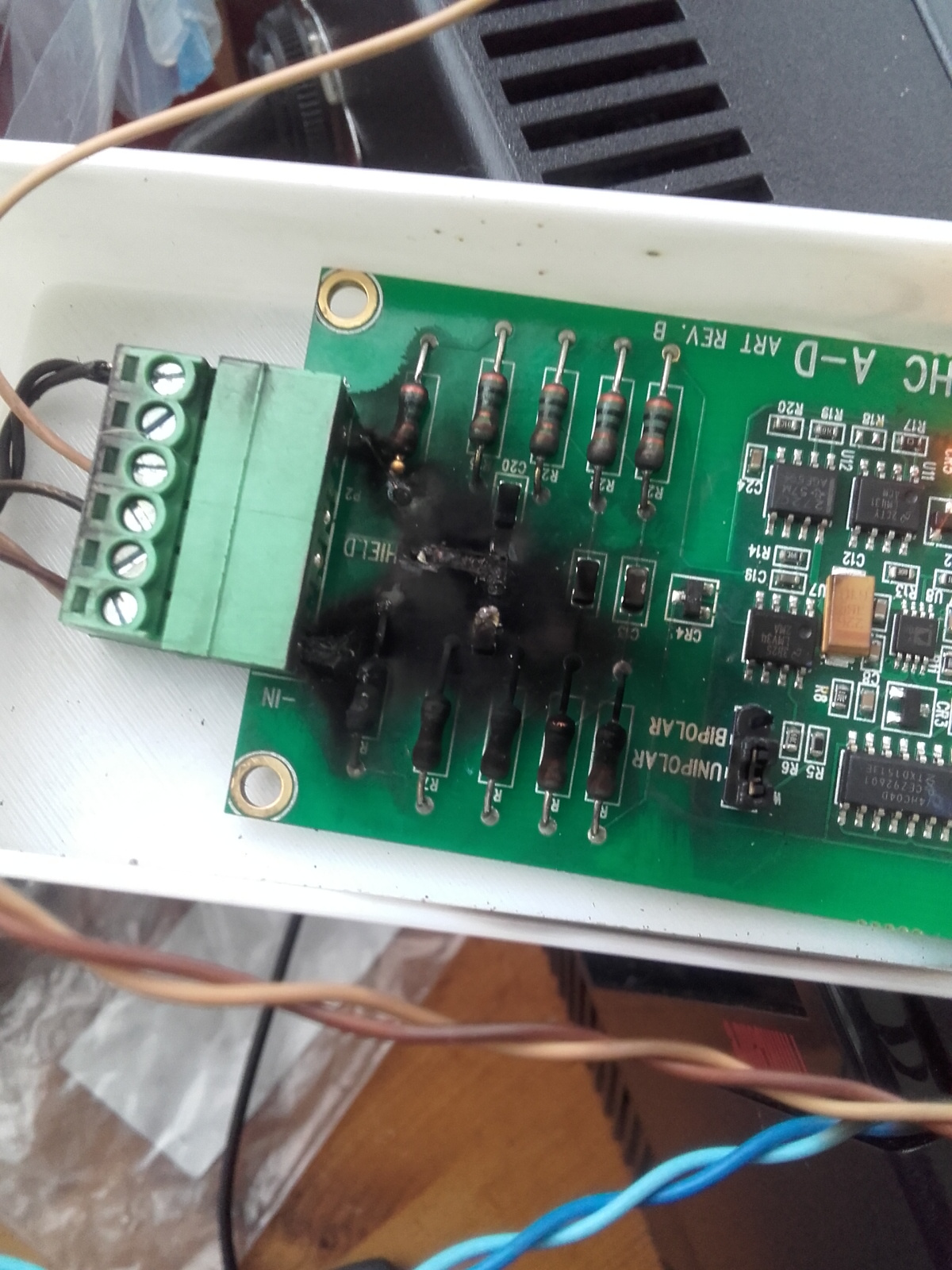

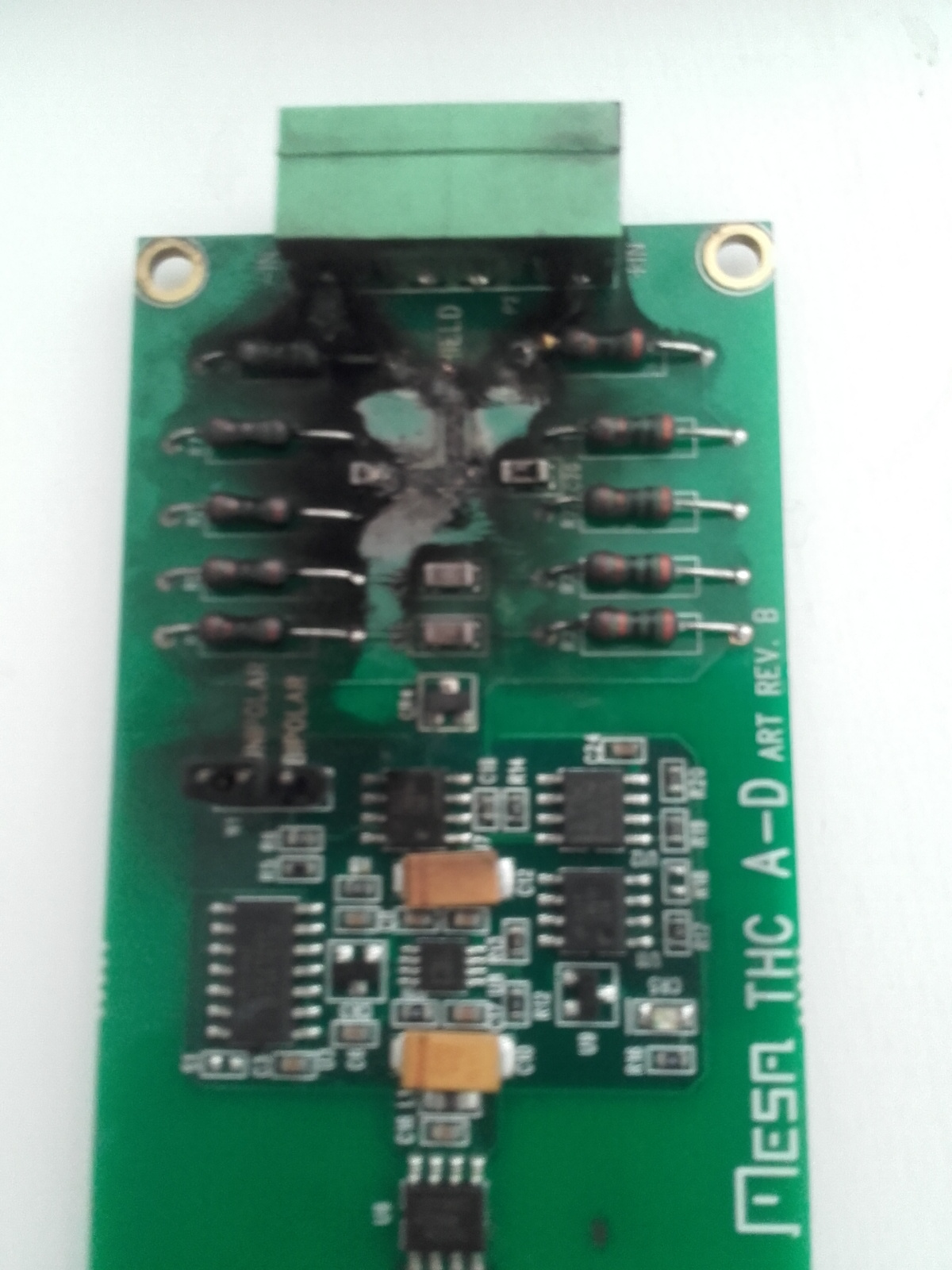

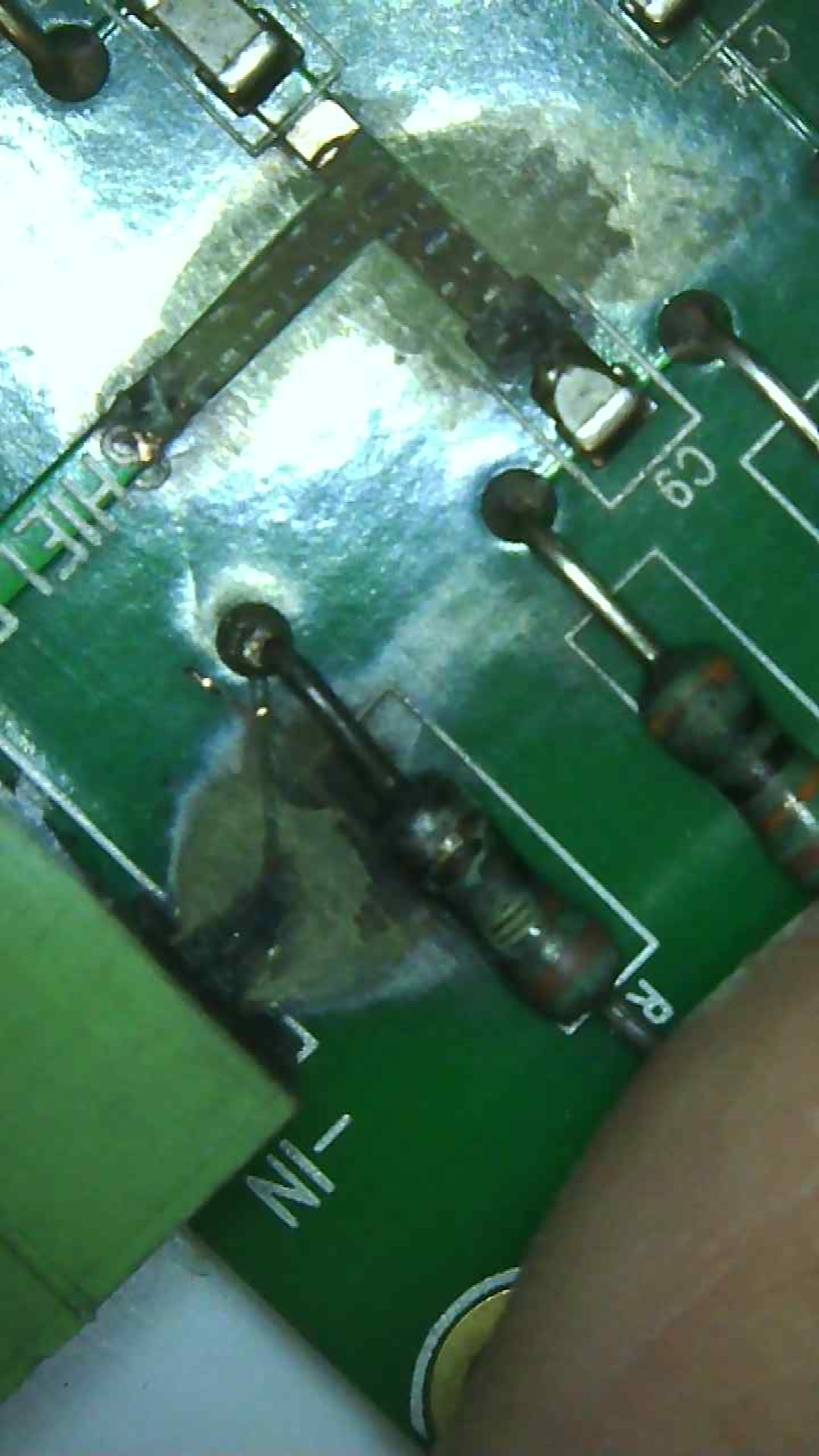

looked like this: seems the shield was smoked off .this was connected to the case of the plasma and the controler box ground (case)....

I reconnected the shield as I had it before ,

I had shortly a voltage reading then it went to nirvana and puffed off.

-in was the torch

+in was the clamp

Like I asked here for clarification forum.linuxcnc.org/plasma-laser/36837-ne...ion?start=180#157751

interesting that the ground smoked off in first place ...ground was connected to ground plasma and ground controller box as mentioned already.

I will order another one as soon as possible . I don't think I can repair it ...voltage showed also without the card -43 Volt!!

all the best !!

Maybe somebody from Mesa has an idea why?

Would a PromaTHC be an option and usable with Plasmac?

I checked the card which was in inside the plasma in a 3dprinted box.

looked like this: seems the shield was smoked off .this was connected to the case of the plasma and the controler box ground (case)....

I reconnected the shield as I had it before ,

I had shortly a voltage reading then it went to nirvana and puffed off.

-in was the torch

+in was the clamp

Like I asked here for clarification forum.linuxcnc.org/plasma-laser/36837-ne...ion?start=180#157751

interesting that the ground smoked off in first place ...ground was connected to ground plasma and ground controller box as mentioned already.

I will order another one as soon as possible . I don't think I can repair it ...voltage showed also without the card -43 Volt!!

all the best !!

Maybe somebody from Mesa has an idea why?

Would a PromaTHC be an option and usable with Plasmac?

Attachments:

Last edit: 23 Mar 2020 16:02 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Mar 2020 16:57 #161236

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

23 Mar 2020 18:54 #161245

by rodw

Replied by rodw on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Ouch Fred, Welcome to the Club.

forum.linuxcnc.org/27-driver-boards/3425...-my-thcad-10?start=0

What you will have to do is check that the encoder input has not been damaged on your main board. Mine was damaged but it was a different fault.

I'm sure PCW will advise how to check this. If it is damaged, it won't be the end of the world. The good news is that by installing different firmware, you will have two more encoder inputs to conduct your fire experiments with.

Others will know a lot more than me about the possible cause. I think I would use single core unshielded wire on the high voltage side with the wires as thick as the THCAD will accept and keep them physically isolated from each other.

forum.linuxcnc.org/27-driver-boards/3425...-my-thcad-10?start=0

What you will have to do is check that the encoder input has not been damaged on your main board. Mine was damaged but it was a different fault.

I'm sure PCW will advise how to check this. If it is damaged, it won't be the end of the world. The good news is that by installing different firmware, you will have two more encoder inputs to conduct your fire experiments with.

Others will know a lot more than me about the possible cause. I think I would use single core unshielded wire on the high voltage side with the wires as thick as the THCAD will accept and keep them physically isolated from each other.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

23 Mar 2020 18:57 - 23 Mar 2020 19:00 #161247

by tommylight

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Maybe not my place to say this, but that is clearly due to arcing, first on the cables and the second time on the THC.

That leads me to conclude two things:

You have a high frequency/high voltage start plasma source

You have it wired in the wrong place, namely you have it wired at the plasma terminals.

I've mentioned here several times that those types of plasma cutters need to be wired directly to the rectifier output or at a small board with 2 resistors and a capacitor.

Those things put out 20 to 30 thousand volts at each start of the cut, and protecting from them is not easy.

Same thing is valid for high voltage start, but a bit easier to deal with.

Melted resistor pins while the resistors are intact !

Almost forgot, the wiring you used is absolutely not correct, you need high voltage wire with thick shielding, and NO other wires near those high voltage ones. You have all the wires through the same hole! Again a no no when dealing with high voltages.

That leads me to conclude two things:

You have a high frequency/high voltage start plasma source

You have it wired in the wrong place, namely you have it wired at the plasma terminals.

I've mentioned here several times that those types of plasma cutters need to be wired directly to the rectifier output or at a small board with 2 resistors and a capacitor.

Those things put out 20 to 30 thousand volts at each start of the cut, and protecting from them is not easy.

Same thing is valid for high voltage start, but a bit easier to deal with.

Melted resistor pins while the resistors are intact !

Almost forgot, the wiring you used is absolutely not correct, you need high voltage wire with thick shielding, and NO other wires near those high voltage ones. You have all the wires through the same hole! Again a no no when dealing with high voltages.

Last edit: 23 Mar 2020 19:00 by tommylight. Reason: added more info

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17698

- Thank you received: 5175

23 Mar 2020 19:10 #161252

by PCW

Replied by PCW on topic Valid Arc Lost, Thcad 300 config & Plasmac override

As you may have noticed  you cannot use a THCAD300 for a HF Start Plasma

you cannot use a THCAD300 for a HF Start Plasma

machines. Even though it uses 10X 3500V rated resistors it will not withstand the

power dissipation when 20-30KV is applied = >100W!

HFstart plasma machines need an external divider with multiple high wattage HV

resistors and a filter

machines. Even though it uses 10X 3500V rated resistors it will not withstand the

power dissipation when 20-30KV is applied = >100W!

HFstart plasma machines need an external divider with multiple high wattage HV

resistors and a filter

The following user(s) said Thank You: rodw, CNCFred

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

23 Mar 2020 19:13 #161254

by tommylight

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

I am pretty sure it says that on the website and in the manual.As you may have noticed

you cannot use a THCAD300 for a HF Start Plasma

machines.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

23 Mar 2020 19:49 #161261

by Clive S

Replied by Clive S on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Cat 5 cable !!!

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

23 Mar 2020 20:10 - 23 Mar 2020 20:29 #161266

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

I must have been mistaken.

I got a Stahlwerk Cut P70

www.stahlwerk-schweissgeraete.de/CUT-70_2

I thought pilot ignition is non HF and the one to use. From the web page.

The CUT 70 has a pilot ignition, a maximum cutting thickness of 25 mm and requires a three-phase alternating current connection.

You are right I used cat 5, being the opinion small current...non HF.

You are also right resistors are OK! Just pins off and the capacitors gone.

How do I test the encoders and what should I do now?

Can the thcad 300 be repaired if I solder in capacitors?

How can I identify the rectifier output?

&thank you very much!

I got a Stahlwerk Cut P70

www.stahlwerk-schweissgeraete.de/CUT-70_2

I thought pilot ignition is non HF and the one to use. From the web page.

The CUT 70 has a pilot ignition, a maximum cutting thickness of 25 mm and requires a three-phase alternating current connection.

You are right I used cat 5, being the opinion small current...non HF.

You are also right resistors are OK! Just pins off and the capacitors gone.

How do I test the encoders and what should I do now?

Can the thcad 300 be repaired if I solder in capacitors?

How can I identify the rectifier output?

&thank you very much!

Last edit: 23 Mar 2020 20:29 by CNCFred.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.277 seconds