Valid Arc Lost, Thcad 300 config & Plasmac override

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

29 Mar 2020 13:39 - 29 Mar 2020 13:41 #161968

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Last edit: 29 Mar 2020 13:41 by CNCFred.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

29 Mar 2020 14:34 #161970

by tommylight

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

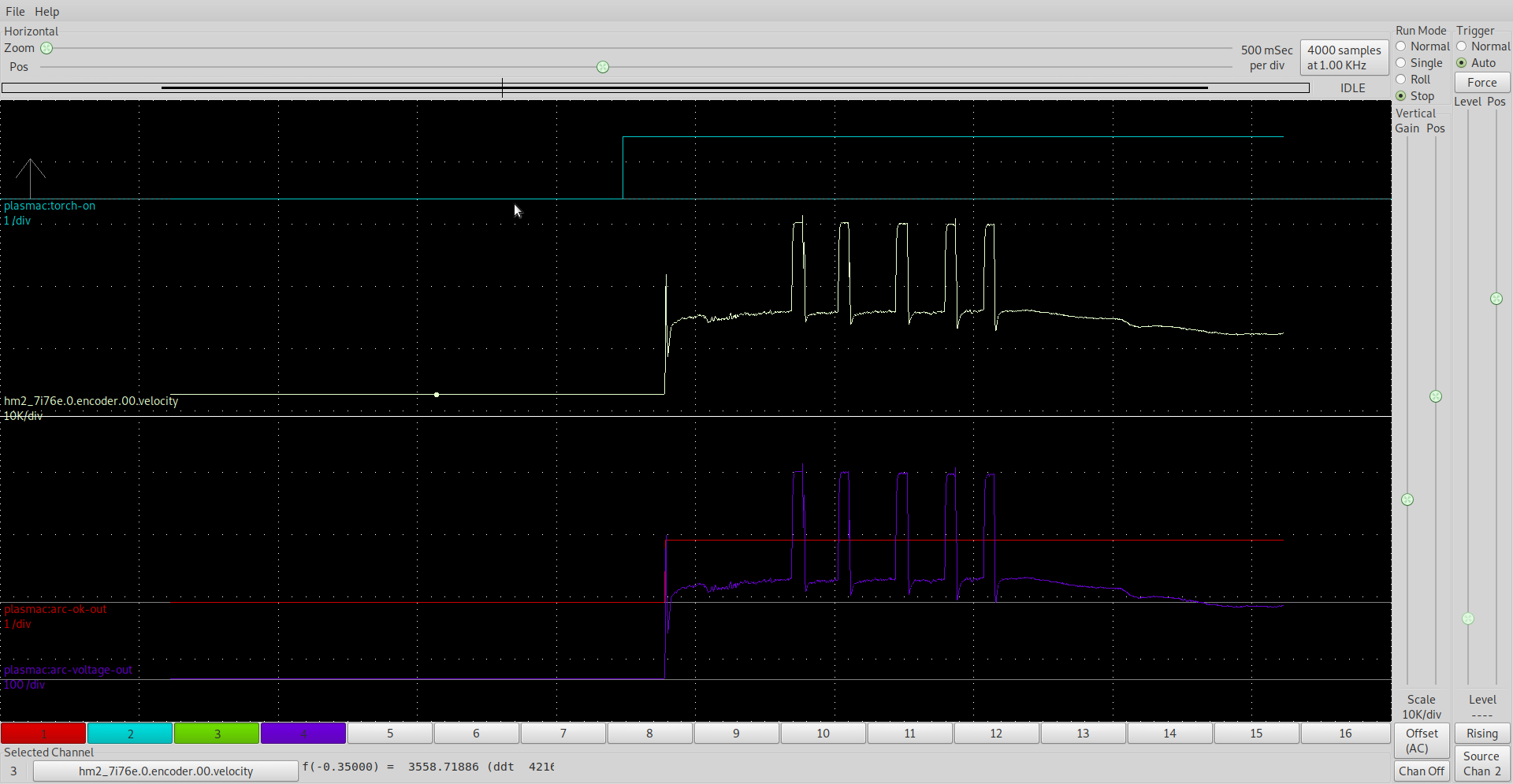

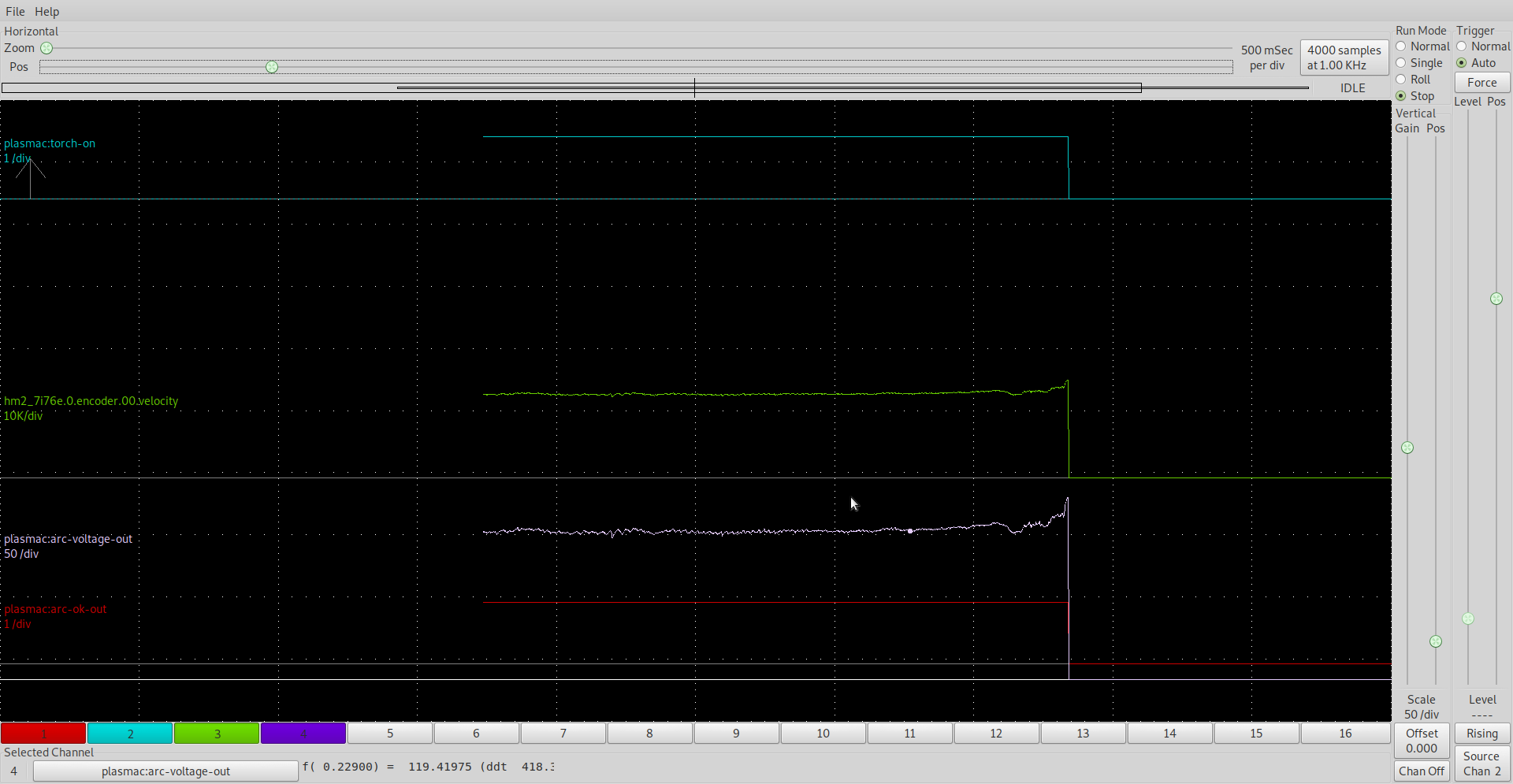

What are those spikes? Kerf crossings ?

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

29 Mar 2020 14:38 - 29 Mar 2020 15:00 #161971

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

I measured the voltage now at the points of the connection thc with a DVM , it is the same ....DC!! with DVM measured..

Last edit: 29 Mar 2020 15:00 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

29 Mar 2020 14:58 #161974

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

29 Mar 2020 16:27 #161996

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

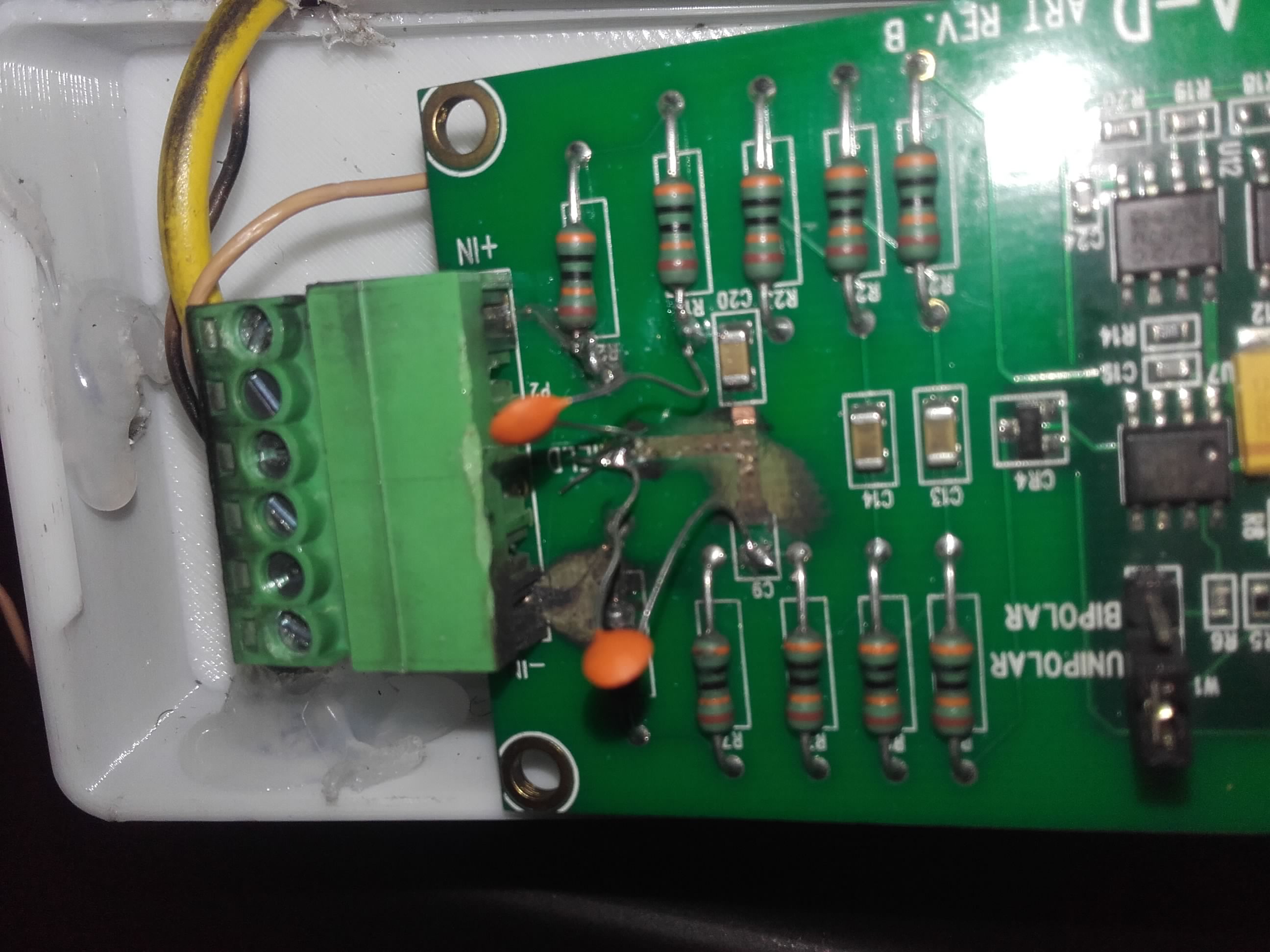

Tommylight Thx for giving the hint about a motor cover...

Ugly fix but working (I am not proud of it) , I used cut off resistor legs as replacement for the broken conductor tracks.(other side)

I am quite happy to have bought Mesa cards! Good choice!

I hope PCW is surprised what his cards can do..... (just kidding)

Ugly fix but working (I am not proud of it) , I used cut off resistor legs as replacement for the broken conductor tracks.(other side)

I am quite happy to have bought Mesa cards! Good choice!

I hope PCW is surprised what his cards can do..... (just kidding)

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- billykid

-

- Offline

- Platinum Member

-

Less

More

- Posts: 468

- Thank you received: 80

29 Mar 2020 18:46 #162014

by billykid

Replied by billykid on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Well !! hf discharges are spectacular but do not do much damage. the important thing is to clean the carbon residues well, maybe even remove the connector to clean better.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Mar 2020 22:02 #162031

by phillc54

Replied by phillc54 on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Sorry, I should have suggested a Buildbot install...

Those messages about missing parameters in the .cfg are only for information, they won't affect anything and will be populated if you click Save on the panel.

I am glad you are up and running, now for some fine tuning.

Those messages about missing parameters in the .cfg are only for information, they won't affect anything and will be populated if you click Save on the panel.

I am glad you are up and running, now for some fine tuning.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

29 Mar 2020 22:28 #162037

by tommylight

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

Oh now you're making parts ! Show-off !

Nice, glad you got it working.

Nice, glad you got it working.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

30 Mar 2020 20:41 - 30 Mar 2020 20:42 #162139

by CNCFred

Replied by CNCFred on topic Valid Arc Lost, Thcad 300 config & Plasmac override

I changed my single wires which connect my limit switches for cat5 cables. (I love those) Looks much neater when they are not singled.

Fine tuning will start now(a hint where to start?), shops are closed here and I can't buy sheet metal.

I am using post processor for fusion 360 so I will need to get aquainted with gcode and how kerf width is compensated. Still a long way to go.

I appreciate your help very much.

Thank you

Fine tuning will start now(a hint where to start?), shops are closed here and I can't buy sheet metal.

I am using post processor for fusion 360 so I will need to get aquainted with gcode and how kerf width is compensated. Still a long way to go.

I appreciate your help very much.

Thank you

Last edit: 30 Mar 2020 20:42 by CNCFred.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

30 Mar 2020 21:41 #162151

by tommylight

The longer version would be deciding what will you be cutting mostly and fine tuning those cut parameters, again it will require testing, but after a while you get a rough idea of what should be cut with what parameters. Look for clean and dross free cuts on the underside, or dross that is easy to remove. While cutting metal, look under the sheet and check that the arc is in front of the cut by 5 to 15 degrees.

It depends a lot on the material composition also, so there is no exact recipe.

Replied by tommylight on topic Valid Arc Lost, Thcad 300 config & Plasmac override

The short version is: test and see what you get.Fine tuning will start now(a hint where to start?), shops are closed here and I can't buy sheet metal.

The longer version would be deciding what will you be cutting mostly and fine tuning those cut parameters, again it will require testing, but after a while you get a rough idea of what should be cut with what parameters. Look for clean and dross free cuts on the underside, or dross that is easy to remove. While cutting metal, look under the sheet and check that the arc is in front of the cut by 5 to 15 degrees.

It depends a lot on the material composition also, so there is no exact recipe.

The following user(s) said Thank You: phillc54, CNCFred

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.169 seconds