Downdraft design questions

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

05 Nov 2020 19:25 #188427

by txtrone

Replied by txtrone on topic Downdraft design questions

This is what I ordered for testing purposes, 1ea only. Going to pick it up later today. Tomorrow I am going to block all but one of the ports on the vent tube and then cut directly over it to see how the 800CFM (at 0 SP) fan does. If that works I will move to the next stage.

www.alliedelec.com/product/smc-corporation/vdw10aa/70907905/

www.alliedelec.com/product/smc-corporati...mb075-0400/70070579/

www.alliedelec.com/product/smc-corporation/vdw10aa/70907905/

www.alliedelec.com/product/smc-corporati...mb075-0400/70070579/

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

05 Nov 2020 19:42 - 05 Nov 2020 19:43 #188429

by rodw

Replied by rodw on topic Downdraft design questions

Looks perfect!

I never went ahead with a downdraft table. The fan I have is one of these www.machineryhouse.com.au/F050

60 m3/min = 2120 cfm which is right on the 3' x 3' zone of 2025 cfm

But now I've seen your design, I am tempted again after I cleaned out my water tray yesterday!

I never went ahead with a downdraft table. The fan I have is one of these www.machineryhouse.com.au/F050

60 m3/min = 2120 cfm which is right on the 3' x 3' zone of 2025 cfm

But now I've seen your design, I am tempted again after I cleaned out my water tray yesterday!

Last edit: 05 Nov 2020 19:43 by rodw.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

05 Nov 2020 20:27 #188441

by txtrone

Replied by txtrone on topic Downdraft design questions

That would be great if you did, so I can follow along! lol

I hope I'm not getting the cart too far in front of the horse. I have yet to connect my new LinuxCNC PC to the Mesa card. Not sure of the 'best' way to cut over from CandCNC setup to the new setup. Perhaps I will use the same plug style for my motors so I can still use the table while I learn the new system.

Kind of off topic, but do you know if the CandCNC Super Z II will work with the gear I purchased, which is the list you made for me. I did end up adding a few things, I got a 7176E as well as a Geckodrive G540.

I hope I'm not getting the cart too far in front of the horse. I have yet to connect my new LinuxCNC PC to the Mesa card. Not sure of the 'best' way to cut over from CandCNC setup to the new setup. Perhaps I will use the same plug style for my motors so I can still use the table while I learn the new system.

Kind of off topic, but do you know if the CandCNC Super Z II will work with the gear I purchased, which is the list you made for me. I did end up adding a few things, I got a 7176E as well as a Geckodrive G540.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

07 Nov 2020 01:47 #188559

by txtrone

Replied by txtrone on topic Downdraft design questions

We mocked this up today. I grabbed the wrong solenoid type, so we were limited to only one motion... also the air pressure was a bit on the high side.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

08 Nov 2020 07:40 #188654

by rodw

Replied by rodw on topic Downdraft design questions

Just watch the video here and get a similar valve. (5/2)

tameson.com/52-way-and-42-way-pneumatic-valve.html

tameson.com/52-way-and-42-way-pneumatic-valve.html

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 49

08 Nov 2020 12:20 - 08 Nov 2020 13:35 #188662

by Himarc3D

Replied by Himarc3D on topic Downdraft design questions

You need to buy 2 silencer too with you use 5/2 (the gold piece at Rodw video)

Your cylinder model dont have cushion just bumper optional with no cost but you need too choose it. If you buy speed controler you dont wear your cylinder and reduce the noise at the end of stroke. I think you dont need full stroke so just 1 speed controller for the retract side is fine IMO but im always use 2 because customer requisite

You can use the 2/2 but need another 2 and need 3 output to control it using logic and at least one sensor to know the stroke position (5/2 is more easy because you dont know yet to program)

www.bimba.com/sites/default/files/Librar..._Pneumatic_Bimba.pdf

CKD solenoid valve is nice too if you can find it, you can abuse it a lot. SMC for manifold i like.

pneumatic we use CKD and SMC, Hydraulic Tayo/Parker.

Your cylinder model dont have cushion just bumper optional with no cost but you need too choose it. If you buy speed controler you dont wear your cylinder and reduce the noise at the end of stroke. I think you dont need full stroke so just 1 speed controller for the retract side is fine IMO but im always use 2 because customer requisite

You can use the 2/2 but need another 2 and need 3 output to control it using logic and at least one sensor to know the stroke position (5/2 is more easy because you dont know yet to program)

www.bimba.com/sites/default/files/Librar..._Pneumatic_Bimba.pdf

CKD solenoid valve is nice too if you can find it, you can abuse it a lot. SMC for manifold i like.

pneumatic we use CKD and SMC, Hydraulic Tayo/Parker.

Last edit: 08 Nov 2020 13:35 by Himarc3D.

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

08 Nov 2020 19:41 #188685

by txtrone

Replied by txtrone on topic Downdraft design questions

Ok, I ordered some speed controllers... but no silencers. The silencer goes on the exhaust port of the solenoid?

If you were going to control eight of the dual action model cylinders, which manifold and valves would you choose. SMC is carried by a local vendor, but the options and configurations were hurting my head. It would be nice to have a manifold with some sort of cables harness that plugs into it and a multi-conductor cable home run to the electronic cabinet. Thanks!

If you were going to control eight of the dual action model cylinders, which manifold and valves would you choose. SMC is carried by a local vendor, but the options and configurations were hurting my head. It would be nice to have a manifold with some sort of cables harness that plugs into it and a multi-conductor cable home run to the electronic cabinet. Thanks!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

08 Nov 2020 20:04 #188688

by rodw

Replied by rodw on topic Downdraft design questions

If you use the 5/2 valves, you have two exhaust ports per valve. I'm no expert but as you will only ever get 2 valves activating at once (one extending, one closing) as you cross a zone boundary, you might be able to connect each side to a manifold and then you would only need two silencers which could be mounted remotely.

You should be able to use a DB9 cable as you only need one common ground wire for all valves. If you want something more industrial there are plenty of circular connectors. One cheap one you should be able to find on ebay is a Weipu SP21 series. They have 9 pin and 12 pin.

You should be able to use a DB9 cable as you only need one common ground wire for all valves. If you want something more industrial there are plenty of circular connectors. One cheap one you should be able to find on ebay is a Weipu SP21 series. They have 9 pin and 12 pin.

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

08 Nov 2020 20:11 #188690

by txtrone

Replied by txtrone on topic Downdraft design questions

Correct. I should have posted that as a question to Himarc3D.

A brand he mentioned, SMC, makes industrial versions with manifold and bus wiring combined. If this experiment works with the cheap 5/2 valves that I bought on Amazon, I would be willing to order a custom 8 station 5/2 valve with the correct manifold and wire harness.

A brand he mentioned, SMC, makes industrial versions with manifold and bus wiring combined. If this experiment works with the cheap 5/2 valves that I bought on Amazon, I would be willing to order a custom 8 station 5/2 valve with the correct manifold and wire harness.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

09 Nov 2020 12:44 #188738

by rodw

Replied by rodw on topic Downdraft design questions

Ok, unzip this folder into your config folder. it will create a folder called gantry which is a basic sim I've edited to be your 6' x 12' table.

Navigate to that folder in a terminal window. typeCheck for errors and resolve or report back

turn on, home all. Load the ddraft.ngc file in the gantry folder.

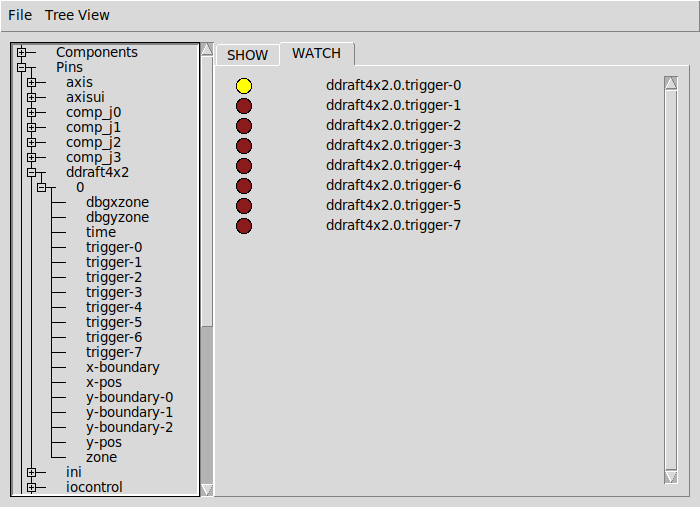

From the machine menu, select show hal configuration. Select the watch tab.

in the tree for pins, find the ddraft4x2.0 component and click on all 8 triggers (numbered 0 to 7) to watch each pin.

run the ngc file and watch the magic happen!

Next step is to connect each trigger pin to a real output pin. (Remember what I said about diodes). I generally would do it like this:

So if you wish to change the zone boundaries you can edit ddraft4x2.hal file to change them

To go live, copy ddraft4x2.hal to your config folder and edit your ini file in a text editor (I use Geany!) and add it to the [HAL] section

Good luck!

Navigate to that folder in a terminal window. type

sudo halcompile --install ddraft4x2.compturn on, home all. Load the ddraft.ngc file in the gantry folder.

From the machine menu, select show hal configuration. Select the watch tab.

in the tree for pins, find the ddraft4x2.0 component and click on all 8 triggers (numbered 0 to 7) to watch each pin.

run the ngc file and watch the magic happen!

Next step is to connect each trigger pin to a real output pin. (Remember what I said about diodes). I generally would do it like this:

net zone0 <= ddraft4x2.0.trigger-0

net zone0 => hm2_7i76e.0.7i76.0.0.output-00So if you wish to change the zone boundaries you can edit ddraft4x2.hal file to change them

To go live, copy ddraft4x2.hal to your config folder and edit your ini file in a text editor (I use Geany!) and add it to the [HAL] section

[HAL]

HALFILE = ddraft4x2.halGood luck!

Attachments:

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.140 seconds