Downdraft design questions

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

11 Nov 2020 23:30 #189067

by txtrone

I am going to get the 5HP belt drive and see what that can do.

Is it possible to overlap the zones so that certain areas of the table that would trigger two gates to be open... sort of like a transition zone?

Replied by txtrone on topic Downdraft design questions

...but will need more fan output...

I am going to get the 5HP belt drive and see what that can do.

Is it possible to overlap the zones so that certain areas of the table that would trigger two gates to be open... sort of like a transition zone?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

12 Nov 2020 08:02 #189092

by rodw

Possibly, but the risk would be that if the torch passes over or near a corner where 4 zones meet, all 4 would turn on which might be too much. slowing the rams down might have a similar affect,

We cut down a roll of wire reinforced rubber hose into short pieces with a chop saw today and we set up my yellow in line fan behind the chop saw with a flexible duct attached. It was actually quite effective catching sparks and smoke so I think you'll be surprised how effective this will be.

Replied by rodw on topic Downdraft design questions

...but will need more fan output...

I am going to get the 5HP belt drive and see what that can do.

Is it possible to overlap the zones so that certain areas of the table that would trigger two gates to be open... sort of like a transition zone?

Possibly, but the risk would be that if the torch passes over or near a corner where 4 zones meet, all 4 would turn on which might be too much. slowing the rams down might have a similar affect,

We cut down a roll of wire reinforced rubber hose into short pieces with a chop saw today and we set up my yellow in line fan behind the chop saw with a flexible duct attached. It was actually quite effective catching sparks and smoke so I think you'll be surprised how effective this will be.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

18 Nov 2020 01:38 - 09 Dec 2020 02:04 #189636

by txtrone

Replied by txtrone on topic Downdraft design questions

The blower delivered today, but it came with the wrong size motor. The correct motor is now slated to be here by the 24th.

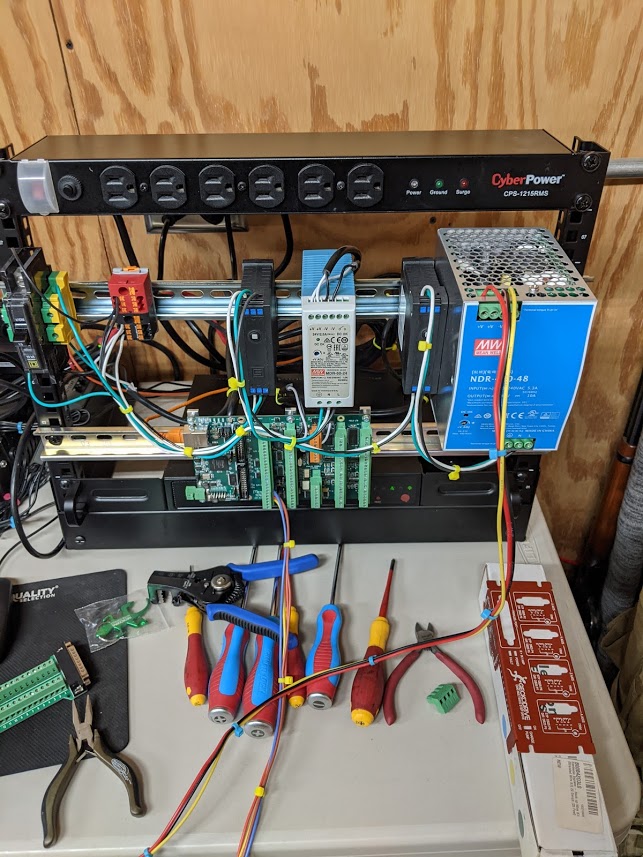

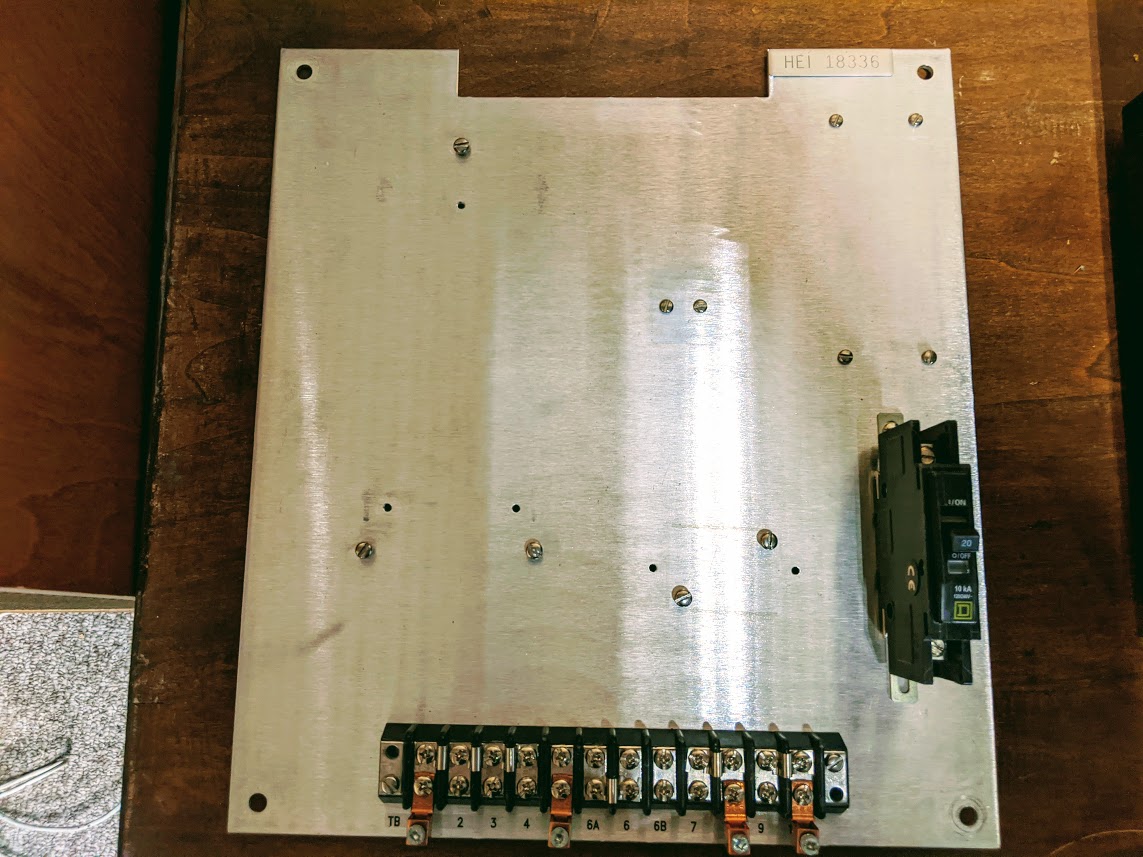

In the meantime I am working on the air manifold for the actuators and also mounted a stainless cabinet (left over from a job) to the table.

When I get the electronic guts figured out I will put them on the back plate and pop them into the cabinet... if it has enough room.

In the meantime I am working on the air manifold for the actuators and also mounted a stainless cabinet (left over from a job) to the table.

When I get the electronic guts figured out I will put them on the back plate and pop them into the cabinet... if it has enough room.

Last edit: 09 Dec 2020 02:04 by txtrone.

The following user(s) said Thank You: rodw, Himarc3D

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

24 Nov 2020 03:46 - 09 Dec 2020 02:04 #190188

by txtrone

Replied by txtrone on topic Downdraft design questions

Attachments:

Last edit: 09 Dec 2020 02:04 by txtrone.

The following user(s) said Thank You: rodw, Himarc3D

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

24 Nov 2020 08:28 #190192

by rodw

Replied by rodw on topic Downdraft design questions

I'm impatiently waiting to see this come together! But don't blame me if it doesn't work!

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

24 Nov 2020 13:32 #190199

by txtrone

What? You said this was guaranteed to work! haha ... just kidding. I think it has a 50% chance of working without further modification.

haha ... just kidding. I think it has a 50% chance of working without further modification.

While researching the various blower motors and fan types I came across air curtains. I wonder if something like that could assist a downdraft table? Just a crazy idea...

I will keep you posted as we slowly progress. The Longs Motor stepper drives showed up yesterday. I have one hobby in front of this one that is eating up a lot of time, but I am getting close to a stopping point on it.

Replied by txtrone on topic Downdraft design questions

...don't blame me if it doesn't work!

What? You said this was guaranteed to work!

While researching the various blower motors and fan types I came across air curtains. I wonder if something like that could assist a downdraft table? Just a crazy idea...

I will keep you posted as we slowly progress. The Longs Motor stepper drives showed up yesterday. I have one hobby in front of this one that is eating up a lot of time, but I am getting close to a stopping point on it.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

24 Nov 2020 13:54 - 24 Nov 2020 13:55 #190200

by rodw

Replied by rodw on topic Downdraft design questions

I can only guarantee the software cos its running on Linuxcnc!

I give you > 50%

I give you > 50%

Last edit: 24 Nov 2020 13:55 by rodw.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

24 Nov 2020 23:55 #190231

by txtrone

Replied by txtrone on topic Downdraft design questions

I am being cautiously pessimistic.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

26 Nov 2020 02:44 - 26 Nov 2020 02:46 #190311

by rodw

Replied by rodw on topic Downdraft design questions

Well I hope this works for you. Looks like I'm joining the club.

This is a Multicam router dust extraction fan the guys next door were throwing out. I'd done them a favour by unloading a truck with my little forklift so I brought it home all of 10 metres when I came back.

They said it had a busted motor but 15 minutes later, we had diagnosed a burnt out switch and I bypassed it in a temporary fashion and its a goer!

OOPS sorry: 1925 CFM 3 HP motor which is generally as big as we go on a single phase circuit

This is a Multicam router dust extraction fan the guys next door were throwing out. I'd done them a favour by unloading a truck with my little forklift so I brought it home all of 10 metres when I came back.

They said it had a busted motor but 15 minutes later, we had diagnosed a burnt out switch and I bypassed it in a temporary fashion and its a goer!

OOPS sorry: 1925 CFM 3 HP motor which is generally as big as we go on a single phase circuit

Attachments:

Last edit: 26 Nov 2020 02:46 by rodw.

The following user(s) said Thank You: tommylight, Himarc3D

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

27 Nov 2020 01:51 - 09 Dec 2020 02:04 #190389

by txtrone

Replied by txtrone on topic Downdraft design questions

That is a great score! It pays to be a friendly neighbor.

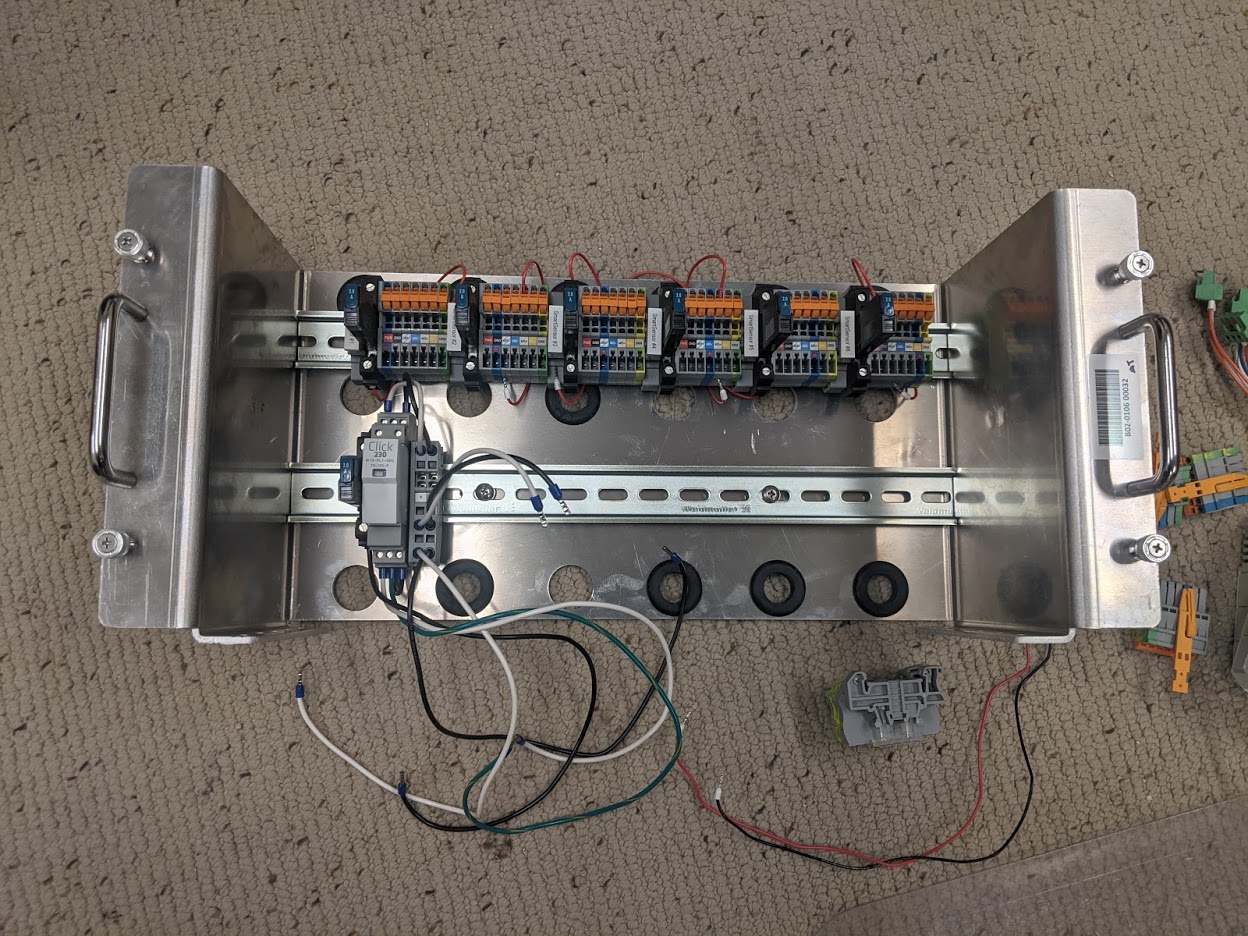

We made a little bit of progress yesterday. Tube is now mounted to the slide out 'trough' for easy access to actuators. Mounts for actuators are on the duct and the doors are ready to go. Still waiting on four more actuators to show up. Hopefully soon.

The bulkhead where the copper lines will transition to plastic tubes is complete.

Is that your Hilux? Also, I could not help but notice the blue stack/hang bins... we use those all over the shop. Greatest thing since canned beer. I even put some on the side of the new table to hold misc consumables and whatnot.

We made a little bit of progress yesterday. Tube is now mounted to the slide out 'trough' for easy access to actuators. Mounts for actuators are on the duct and the doors are ready to go. Still waiting on four more actuators to show up. Hopefully soon.

The bulkhead where the copper lines will transition to plastic tubes is complete.

Is that your Hilux? Also, I could not help but notice the blue stack/hang bins... we use those all over the shop. Greatest thing since canned beer. I even put some on the side of the new table to hold misc consumables and whatnot.

Attachments:

Last edit: 09 Dec 2020 02:04 by txtrone.

The following user(s) said Thank You: tommylight, Himarc3D

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.342 seconds