Hypersensing questions

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

19 Apr 2020 12:51 #164636

by Uthayne

Thanks! Your signal looks so clean even when it's not contacting, I'm jealous. Are you using shielded cable for your ohmic wire?

I'll get out to the garage and capture some data.

Yes, on dry cuts not over water, no issue. Voltage goes right back to 0v. Maybe the hypertherm torches trap more water than TD. Because a trigger pulse definitely does not dry it out enough when it's really wet. It helped when it was 15-16v "wet", but not 23v. Haha kinda a weird thing to say.

I'll capture the data as is and then I'll install ohmic2 and give that a go.

Replied by Uthayne on topic Hypersensing questions

Well, I went to work on a Sunday to have a play for you guys. I have a Thermal Dynamics A120 120 amp machine.

So at the start, everything was nice and normal as everything was dry. Then I used my finger to splash some water into the nozzle and sure enough the volts went up to about 21.6 volts. This is the result of a probe event. I am really interested to see the behaviour when the contact is broken.

So what I'm seeing is a definite downward slope as the connection breaks. This is what I was expecting to see.

And when we zoom in

So it would be good if you guys could post similar screen dumps.

I'm still thinking about how best to proceed from here but clearly we can measure the ramp down as I expected.

I am wondering if the resting voltage could be sampled when is-probing goes true but I don't quite know what the next step would be.

I am assuming you guys are just seeing the 23.5 volts after the torch is wet and not on a dry machine. That is what I thought Uthayne said earlier. Can you confirm? All I hav eto do is blow some air through the torchand its clean again. But I have had to open the torch to dry it before.

Thanks! Your signal looks so clean even when it's not contacting, I'm jealous. Are you using shielded cable for your ohmic wire?

I'll get out to the garage and capture some data.

Yes, on dry cuts not over water, no issue. Voltage goes right back to 0v. Maybe the hypertherm torches trap more water than TD. Because a trigger pulse definitely does not dry it out enough when it's really wet. It helped when it was 15-16v "wet", but not 23v. Haha kinda a weird thing to say.

I'll capture the data as is and then I'll install ohmic2 and give that a go.

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

Less

More

- Posts: 145

- Thank you received: 46

19 Apr 2020 14:25 #164641

by Uthayne

Replied by Uthayne on topic Hypersensing questions

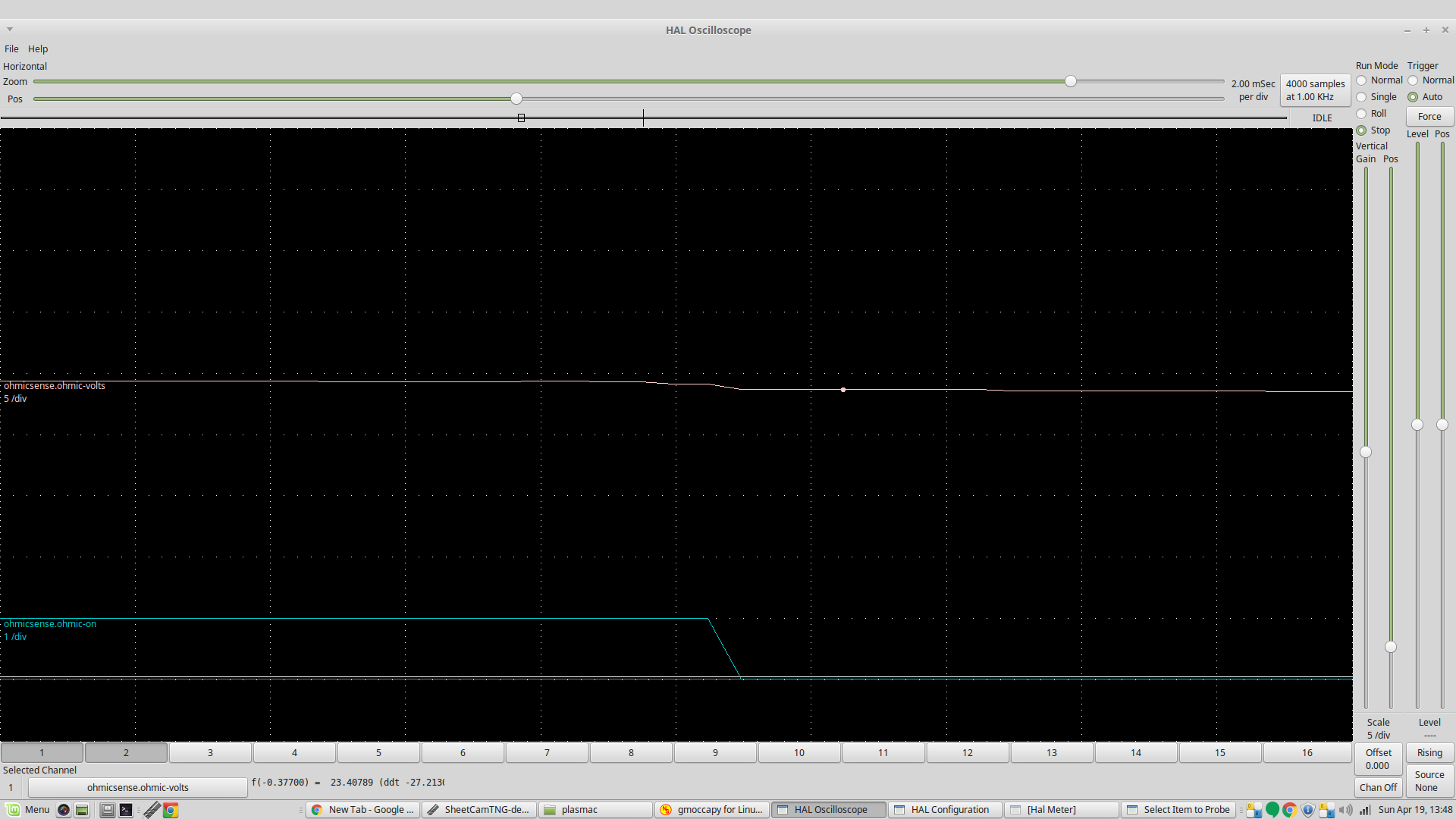

Took same data, here it is.

First off, a dry run. Water has not touched the torch, just going down and probing. Nice and clean.

Then I pulsed the torch over water (not close) to get some voltage. Torch was reading 19v, but still probed happily.

Close up view of the previous.

Then I simulated the end of a cutout where the torch is close to the water and gets drenched. 23v+ is what the torch is sitting at now, rapidly triggering ohmic.

I did a probe event and you can see where it made contact because the ohmic-on signal is true for a bit longer

Close up of previous

I then tried installing ohmic2 but it would not let me probe successfully as it was being triggered before moving to probe height. The reason I was able to in the previous picture is because I modified my own ohmic component to let it, but it was only for troubleshooting.

My "ON" signal for ohmic-volts is nice and clean. When it is floating and water logged, it is quite messy. Perhaps I should investigate wiring or employ some low pass filters?

First off, a dry run. Water has not touched the torch, just going down and probing. Nice and clean.

Then I pulsed the torch over water (not close) to get some voltage. Torch was reading 19v, but still probed happily.

Close up view of the previous.

Then I simulated the end of a cutout where the torch is close to the water and gets drenched. 23v+ is what the torch is sitting at now, rapidly triggering ohmic.

I did a probe event and you can see where it made contact because the ohmic-on signal is true for a bit longer

Close up of previous

I then tried installing ohmic2 but it would not let me probe successfully as it was being triggered before moving to probe height. The reason I was able to in the previous picture is because I modified my own ohmic component to let it, but it was only for troubleshooting.

My "ON" signal for ohmic-volts is nice and clean. When it is floating and water logged, it is quite messy. Perhaps I should investigate wiring or employ some low pass filters?

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

19 Apr 2020 20:30 #164668

by rodw

Replied by rodw on topic Hypersensing questions

Great feedback thanks. From what I can see, its still possible to identify a probe event among the noise which is something nobody previously has thought possible when water enters the torch.

I think it would be good to see if you could use ohmic2 with a high threshold of say 23.95 to 23.99 volts to see if we can capture a probe event and also plot the ohmicsense.dbg_avgv pin which is smoothed by averaging. If we could do that, it might give us a baseline for the next step which is:

to change the component under case 1: fromto

We would then be using a smoothed moving average (N=5) which should flatten out the noisy peaks.

Eg. every reading is the average of the previous N readings. You may need to play around with N so:

If we then change the value of ohmicsense.num-readings (our N) to say 10, it will increase the number of readings averaged. I think that would mean that you would need to be reading 24.0 volts for 10 servo cycles before you saw a reading of 24.0 volts.

This all assumes my moving average code works! I think it does but its hard to test in an interrupt service routine on the servo thread. It will support averaging up to 1000 readings (1 second but we want to keep it as low as possible, certainly no more then N=100 which is 0.1 second.

Hopefully, that will give you some homework and an eventual solution .

I think it would be good to see if you could use ohmic2 with a high threshold of say 23.95 to 23.99 volts to see if we can capture a probe event and also plot the ohmicsense.dbg_avgv pin which is smoothed by averaging. If we could do that, it might give us a baseline for the next step which is:

to change the component under case 1: from

if(ohmic_volts > ohmic_threshold){if(avgvolts > ohmic_threshold){We would then be using a smoothed moving average (N=5) which should flatten out the noisy peaks.

Eg. every reading is the average of the previous N readings. You may need to play around with N so:

If we then change the value of ohmicsense.num-readings (our N) to say 10, it will increase the number of readings averaged. I think that would mean that you would need to be reading 24.0 volts for 10 servo cycles before you saw a reading of 24.0 volts.

This all assumes my moving average code works! I think it does but its hard to test in an interrupt service routine on the servo thread. It will support averaging up to 1000 readings (1 second but we want to keep it as low as possible, certainly no more then N=100 which is 0.1 second.

Hopefully, that will give you some homework and an eventual solution .

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5156

19 Apr 2020 21:30 #164672

by PCW

Replied by PCW on topic Hypersensing questions

The best solution would be to to lower the sensitivity of the ohmic sense by adding a resistor between the probe and the table, raising the current threshold...

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

19 Apr 2020 21:38 #164673

by rodw

Peter thanks, can you suggest a value?

Replied by rodw on topic Hypersensing questions

The best solution would be to to lower the sensitivity of the ohmic sense by adding a resistor between the probe and the table, raising the current threshold...

Peter thanks, can you suggest a value?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5156

19 Apr 2020 22:10 #164677

by PCW

Replied by PCW on topic Hypersensing questions

With no load (other than the THCAD-5) the sense current is 50 uA full scale

If you wanted 20X that (1 mA) , 24K would work.

Assuming that it needs to withstand 300V faults, (where it would dissipate 3.75W)

a 24K 5W resistor would be a good choice

If you wanted 20X that (1 mA) , 24K would work.

Assuming that it needs to withstand 300V faults, (where it would dissipate 3.75W)

a 24K 5W resistor would be a good choice

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

19 Apr 2020 22:50 - 19 Apr 2020 22:52 #164684

by snowgoer540

happy to:

I dont see how it's possible you were getting 2.3M ohms with everything unplugged from the THCAD, unless you were touching the meter probes with your fingers. Otherwise, assuming everything was bone dry, there is literally no connection between the shield and the ground of the either the machine, or the table with the input and output disconnected from the THCAD.

Try this for me, remove your shield, exposing the nozzle, and measure from the nozzle to the ground clamp of the hypertherm. This is how I am getting 16.54K ohm.

Replied by snowgoer540 on topic Hypersensing questions

Does what I’m saying about the resistance even remotely make sense?

Kinda but no. Any additional resistance must be counted (eg raw arc voltage with 2 x 100 k Ohm resistors or the everlast divider board which converts a 16:1 divider to a 24:. BUt what does not make sense is the low resistance you are measuring compared with Myselfg and Ulethane as we had numbers in the MHz which are reported in this thread somewhere.

Unfortunately that conversation was in the other thread (getting difficult to keep track).

snowgoer540, can you mimic these measurements? This is what I measured the other day.

Turned off all power to everything. Plasma cutter still plugged into wall, but off. 24v isolated psu is unplugged Thcad-5 input and output connectors, unplugged Wire on cap, resistance between torch shield and table: 2.3MOhms Wire removed from cap, torch shield to table, resistance is still 2.3MOhms Work clamp removed from table, open circuit, infinite resistance Plasma torch to work clamp resistance is 5.6MOhms

happy to:

Turned off all power to everything. Plasma cutter still plugged into wall, but off.

24v isolated psu is unplugged

Thcad-5 input and output connectors, unplugged

Wire on cap, resistance between torch shield and table: infinite resistance (open circuit)

Wire removed from cap, torch shield to table, resistance is still infinite as the circuit is open

Work clamp removed from table, open circuit, infinite resistance (open curcuit)

Plasma torch to work clamp resistance is 16.54K(I assume you mean from teh nozzle to the clampI dont see how it's possible you were getting 2.3M ohms with everything unplugged from the THCAD, unless you were touching the meter probes with your fingers. Otherwise, assuming everything was bone dry, there is literally no connection between the shield and the ground of the either the machine, or the table with the input and output disconnected from the THCAD.

Try this for me, remove your shield, exposing the nozzle, and measure from the nozzle to the ground clamp of the hypertherm. This is how I am getting 16.54K ohm.

Last edit: 19 Apr 2020 22:52 by snowgoer540.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

19 Apr 2020 22:56 #164686

by snowgoer540

This is what I would have expected. I dont see how the code is solving the problem that the hypersensing is too sensitive. It has a path to ground of 16.5k ohms, so of course it can easily overcome that.

Again, Maybe we are trying to solve two separate issues simultaneously. But until we reduce the false trips due to water intrusion, I'm not sure what the code is going to solve. This part of the ohmic problem seems to be circuitry based. I am with Peter, it needs to be less sensitive. The voltage for water in the torch needs to be lower than the voltage for shield contacting workpiece sitting on table.

I'm willing to try the resistor thing to see what happens, I just dont have any 5 watt or 10 watt resistors laying around, I'll have to order some.

Replied by snowgoer540 on topic Hypersensing questions

I then tried installing ohmic2 but it would not let me probe successfully as it was being triggered before moving to probe height.

This is what I would have expected. I dont see how the code is solving the problem that the hypersensing is too sensitive. It has a path to ground of 16.5k ohms, so of course it can easily overcome that.

Again, Maybe we are trying to solve two separate issues simultaneously. But until we reduce the false trips due to water intrusion, I'm not sure what the code is going to solve. This part of the ohmic problem seems to be circuitry based. I am with Peter, it needs to be less sensitive. The voltage for water in the torch needs to be lower than the voltage for shield contacting workpiece sitting on table.

I'm willing to try the resistor thing to see what happens, I just dont have any 5 watt or 10 watt resistors laying around, I'll have to order some.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

19 Apr 2020 23:19 - 19 Apr 2020 23:19 #164692

by snowgoer540

@PCW

Is the placement of the RED resistor in the attached diagram screen shot what you mean?

Also, What would be the difference between a 10K 10W resistor mentioned previously and the 24K 5W resistor mentioned here?

Replied by snowgoer540 on topic Hypersensing questions

With no load (other than the THCAD-5) the sense current is 50 uA full scale

If you wanted 20X that (1 mA) , 24K would work.

Assuming that it needs to withstand 300V faults, (where it would dissipate 3.75W)

a 24K 5W resistor would be a good choice

@PCW

Is the placement of the RED resistor in the attached diagram screen shot what you mean?

Also, What would be the difference between a 10K 10W resistor mentioned previously and the 24K 5W resistor mentioned here?

Last edit: 19 Apr 2020 23:19 by snowgoer540.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21219

- Thank you received: 7246

19 Apr 2020 23:46 #164696

by tommylight

Replied by tommylight on topic Hypersensing questions

That should do just fine.

Then again, i would try it with a smaller one, see if it burns to a crisp!

Normally it should not burn as it is isolated from the nozzle and the electrode, but PCW is right, during firing more voltage would be induced/conducted through water, and that is a risk not to be taken lightly.

Then again, i would try it with a smaller one, see if it burns to a crisp!

Normally it should not burn as it is isolated from the nozzle and the electrode, but PCW is right, during firing more voltage would be induced/conducted through water, and that is a risk not to be taken lightly.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.244 seconds