Hypersensing questions

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

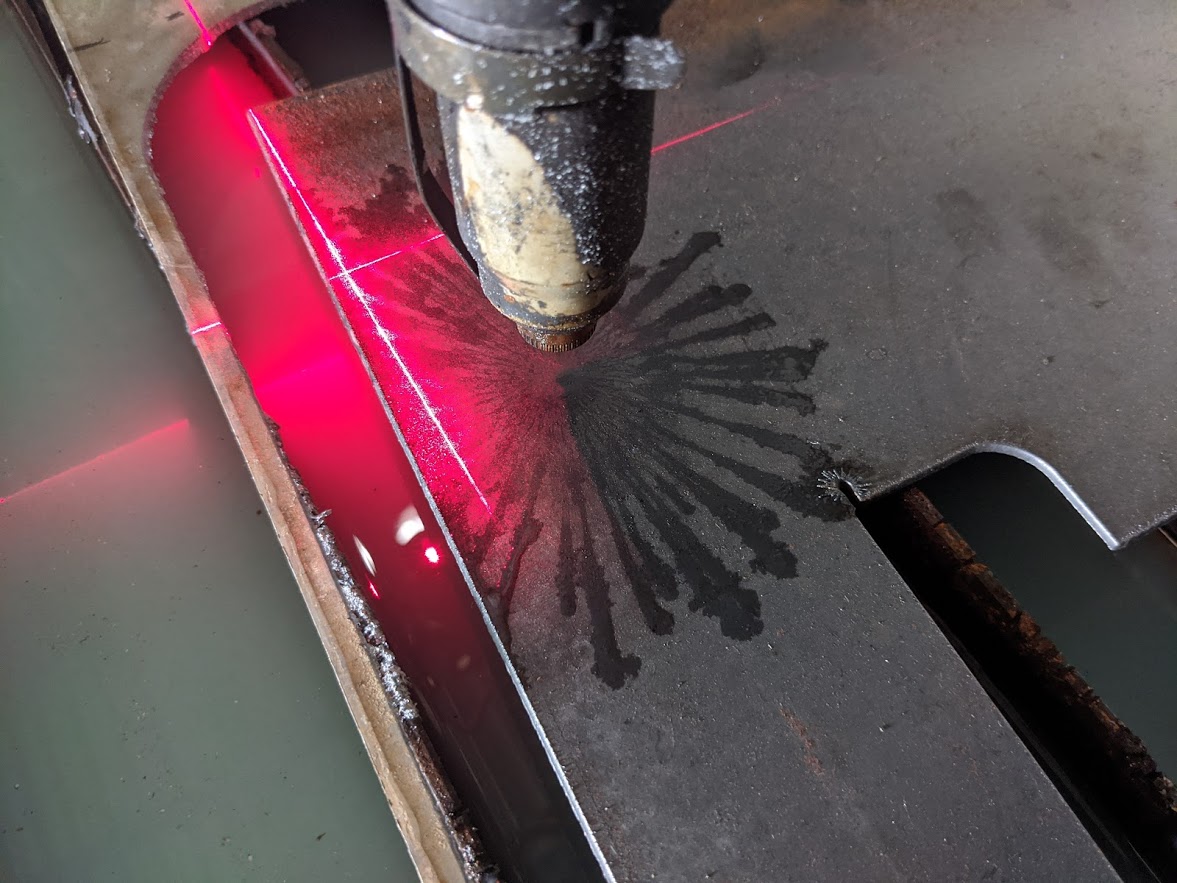

However, if we finish of the experiments here, we will probably have a simple solution that will allow ohmic sensing to be used on water tables reliably where torch design permits its use.

On that note, I think I will put my relay back into the circuit becasue a constant current in the torch tip is probably not good for consumables as some electrolysis may occur... Does anyone have thoughts on that?

Please Log in or Create an account to join the conversation.

- little_sparky

- Offline

- Premium Member

-

- Posts: 138

- Thank you received: 17

Ohmic sensing has its limits (eg can't be used on a torch without a separate shield - eg Everlast) In these situations the simplest solution might be to use an air ram with a spring loaded ohmic probe triggered by plasmac.ohmic-enable signal and use ohmic sensing. That keeps it within the current design parameters and eliminates an shorts in the tip from water as its no longer in the circuit. You could use a proximity sensor with this method too I guess but you'd have to look at repeatability of the returned measurement for the chosen prox sensor.

Any idea how you’d program in the offset so that the air ram comes down, senses near your pierce position, retracts up and then brings your torch to that position? Like In that swift-cut video? I might make a seperate post on this subject.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Edit: oops, I didn't see Rod's reply...

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

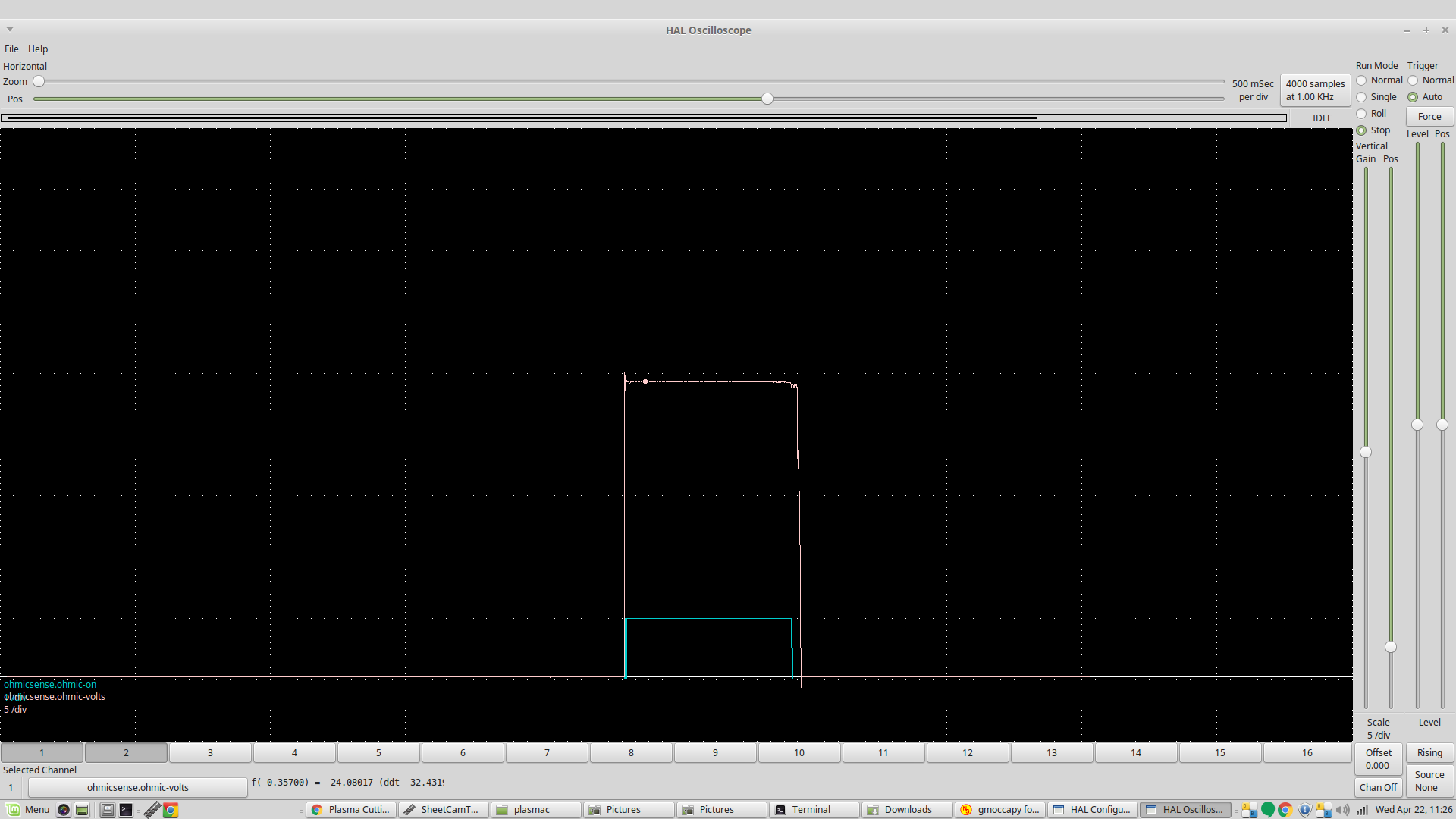

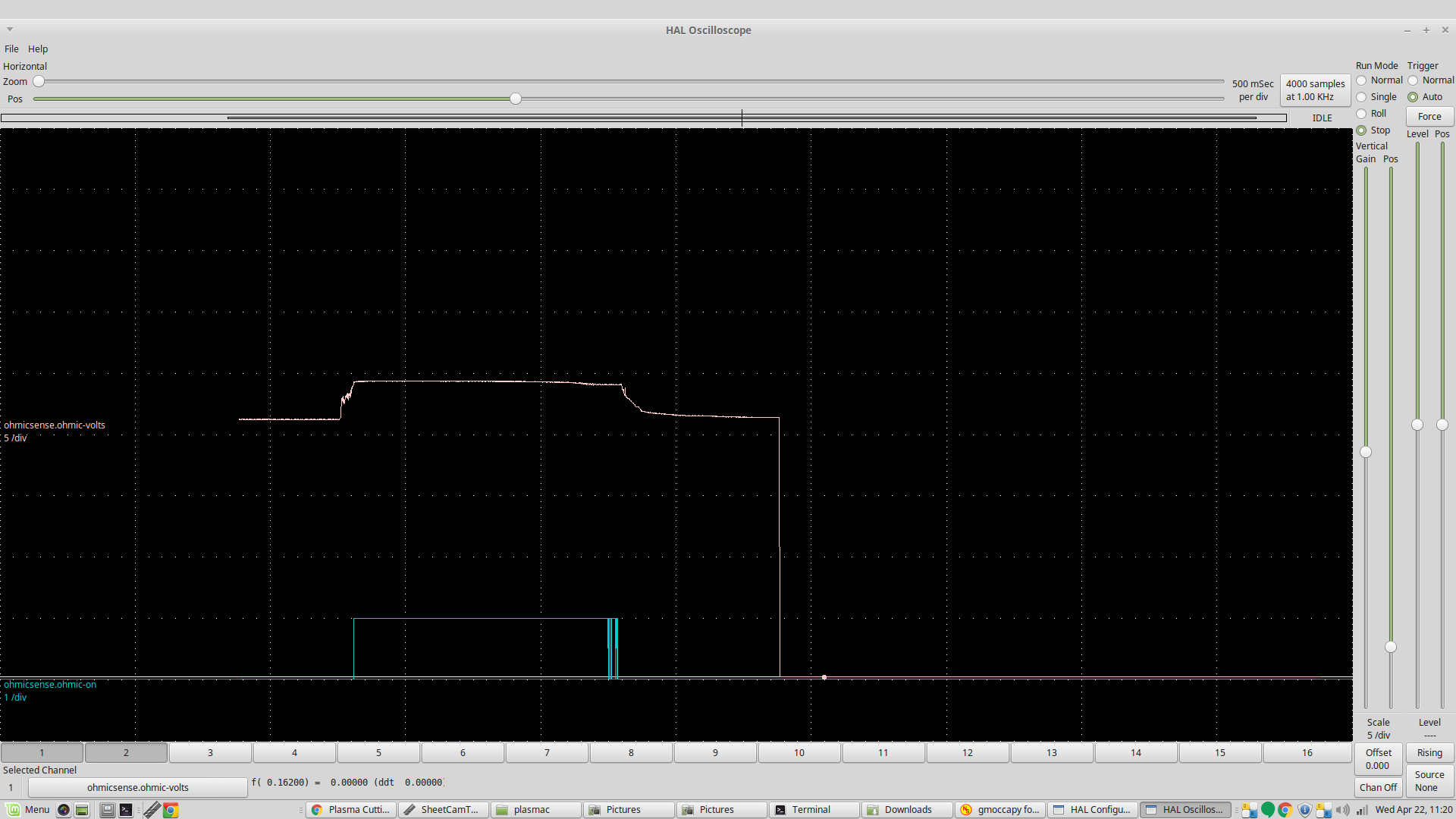

Dry Torch

Wet torch

Goes from about 21 volts to 24 volts so I've set my threshold at 22 volts using mode 1 on my new component

I cut a test part with 48 probes with a wet torch and it did not falter.

Can someone suggest a pin that goes true when we start cutting? I might use that for my relay instead of the is-probing signal? The power supplies take some time to turn on and off so i would be better to turn it on at the beginning of a job.

LittleSparky, you could probably use the float switch feature of Plasmac as it give you a way to set the offsets

Cheers guys. ANd thanks to PCW for coming up with the ideas (and doing the maths!)

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

On that note, I think I will put my relay back into the circuit becasue a constant current in the torch tip is probably not good for consumables as some electrolysis may occur... Does anyone have thoughts on that?

Can someone suggest a pin that goes true when we start cutting? I might use that for my relay instead of the is-probing signal? The power supplies take some time to turn on and off so i would be better to turn it on at the beginning of a job.

Earlier in the thread, Peter did suggest we use relays to prevent electrolysis as you stated. For that reason, I ordered a nice DIN mounted SSR. I would think we want to stick with the is-probing signal, however maybe it's possible to add a small delay for the first probe? Is the time it takes to power up and produce 24V that significant? I actually thought of leaving the Power supply always powered up, and then breaking the DC circuit instead with a relay. It was suggested to me by one of my EE friends that that would probably be really hard on the power supply. I'm still willing to try it though, as in the end they are ~$20.

I think I need to revise the component so when the probe turns off, it stays off until the end of the probing event.

Without thinking about it too hard (it's 6am here), that seems like a good idea. Comes down, gets a solid trip, turns off so there are no more accidental trips, seems like a good security measure. Alternatively, maybe a longer debounce? Honestly, this is another reason I was thinking of a relay breaking the DC side of the circuit instead of the AC side, as it would be an instant off, instant on.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Earlier in the thread, Peter did suggest we use relays to prevent electrolysis as you stated.

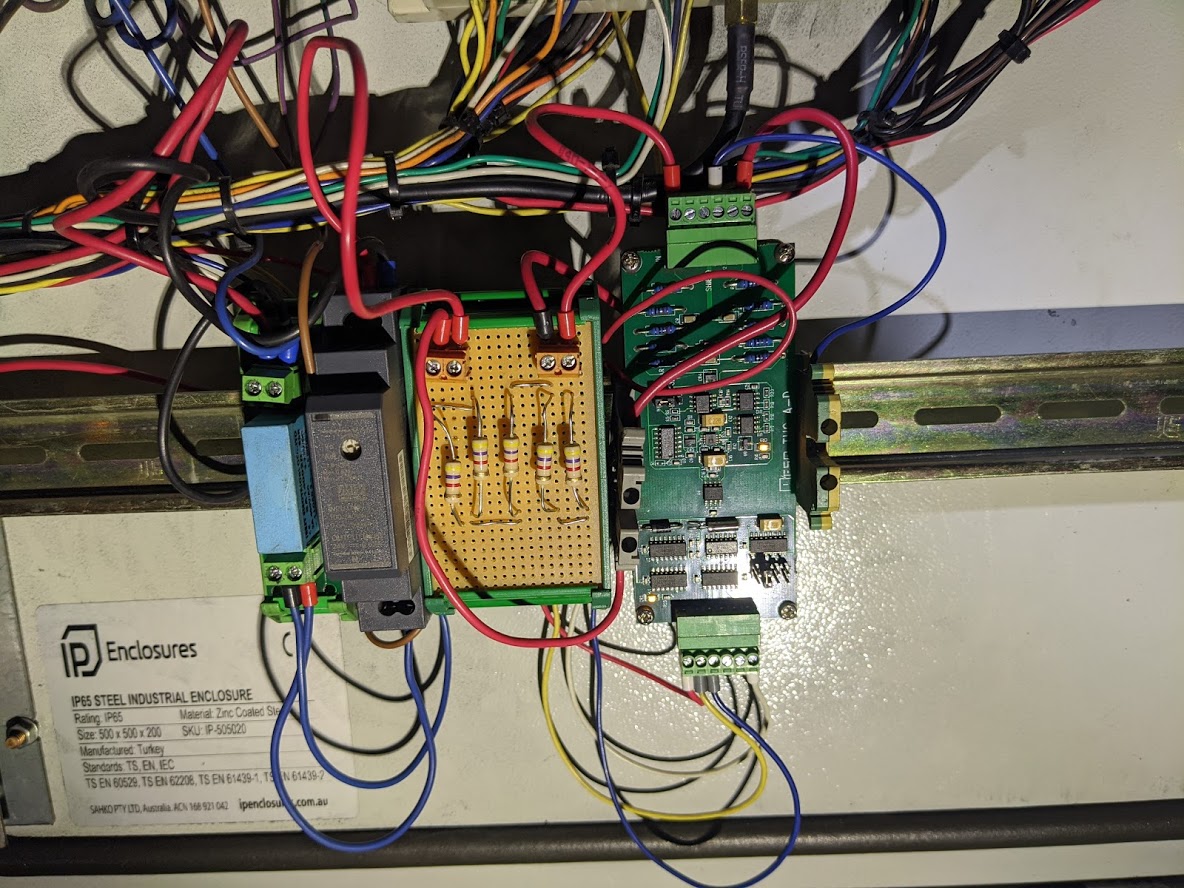

Yeh I think probably I told him that very early in the piece which I why I reinstated mine. I think it was Islander261 who had that advice but he did not have any first hand experience, but it makes sense now. Adding DC relays actually breaks the whole concept behind Hypersensing which was to have noting in the DC circuit. I would try to avoid it. The power supply must have some capacitors in it as it takes a long time for the LED to go off. I Actually saw the voltage count down in halshow today which was wierd. I think I had a similar lag on the first probe as the capacitors charged But plasmac recovered from the error.

I might look at motion.motion-enabled and see what it does. Otherwise, I might use motion.motion-type where it is > 0.

We just want to kill the circuit when its not running.

Anyway 8:30pm here. I will look at the component switch off but probably not until the weekend... Please keep us posted during the day shift

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Earlier in the thread, Peter did suggest we use relays to prevent electrolysis as you stated.

Yeh I think probably I told him that very early in the piece which I why I reinstated mine. I think it was Islander261 who had that advice but he did not have any first hand experience, but it makes sense now. Adding DC relays actually breaks the whole concept behind Hypersensing which was to have noting in the DC circuit. I would try to avoid it. The power supply must have some capacitors in it as it takes a long time for the LED to go off. I Actually saw the voltage count down in halshow today which was wierd. I think I had a similar lag on the first probe as the capacitors charged But plasmac recovered from the error.

I might look at motion.motion-enabled and see what it does. Otherwise, I might use motion.motion-type where it is > 0.

We just want to kill the circuit when its not running.

Anyway 8:30pm here. I will look at the component switch off but probably not until the weekend... Please keep us posted during the day shift

What would be the overall harm in having a relay on the dc side? In other words, why was this being avoided? I would think the original concept might not have accounted for the need to turn it on and off immediately?

I would honestly think the consumable would wear out before electrolysis is a problem... but maybe I’m wrong :shrugs:

Please Log in or Create an account to join the conversation.