Hypersensing questions

- tommylight

-

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

It would take twice as much current to trip, in this case might be even better.[

Also, What would be the difference between a 10K 10W resistor mentioned previously and the 24K 5W resistor mentioned here?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17731

- Thank you received: 5187

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

- Posts: 145

- Thank you received: 46

Turned off all power to everything. Plasma cutter still plugged into wall, but off. 24v isolated psu is unplugged Thcad-5 input and output connectors, unplugged Wire on cap, resistance between torch shield and table: infinite resistance (open circuit) Wire removed from cap, torch shield to table, resistance is still infinite as the circuit is open Work clamp removed from table, open circuit, infinite resistance (open curcuit) Plasma torch to work clamp resistance is 16.54K(I assume you mean from teh nozzle to the clamp

I dont see how it's possible you were getting 2.3M ohms with everything unplugged from the THCAD, unless you were touching the meter probes with your fingers. Otherwise, assuming everything was bone dry, there is literally no connection between the shield and the ground of the either the machine, or the table with the input and output disconnected from the THCAD.

Try this for me, remove your shield, exposing the nozzle, and measure from the nozzle to the ground clamp of the hypertherm. This is how I am getting 16.54K ohm.

Well I went and did the measurements again on a dry torch and got the same that you did. Open circuit, infinite resistance on all readings. It's possible I wasn't careful while measuring last time and was touching the probes. It's quite likely to be honest remembering how much it was varying, or it was with a wet torch? That's embarrassing.

Nozzle to work clamp I got 16.33Kohm. So that checks out.

Please Log in or Create an account to join the conversation.

- Uthayne

- Offline

- Premium Member

-

- Posts: 145

- Thank you received: 46

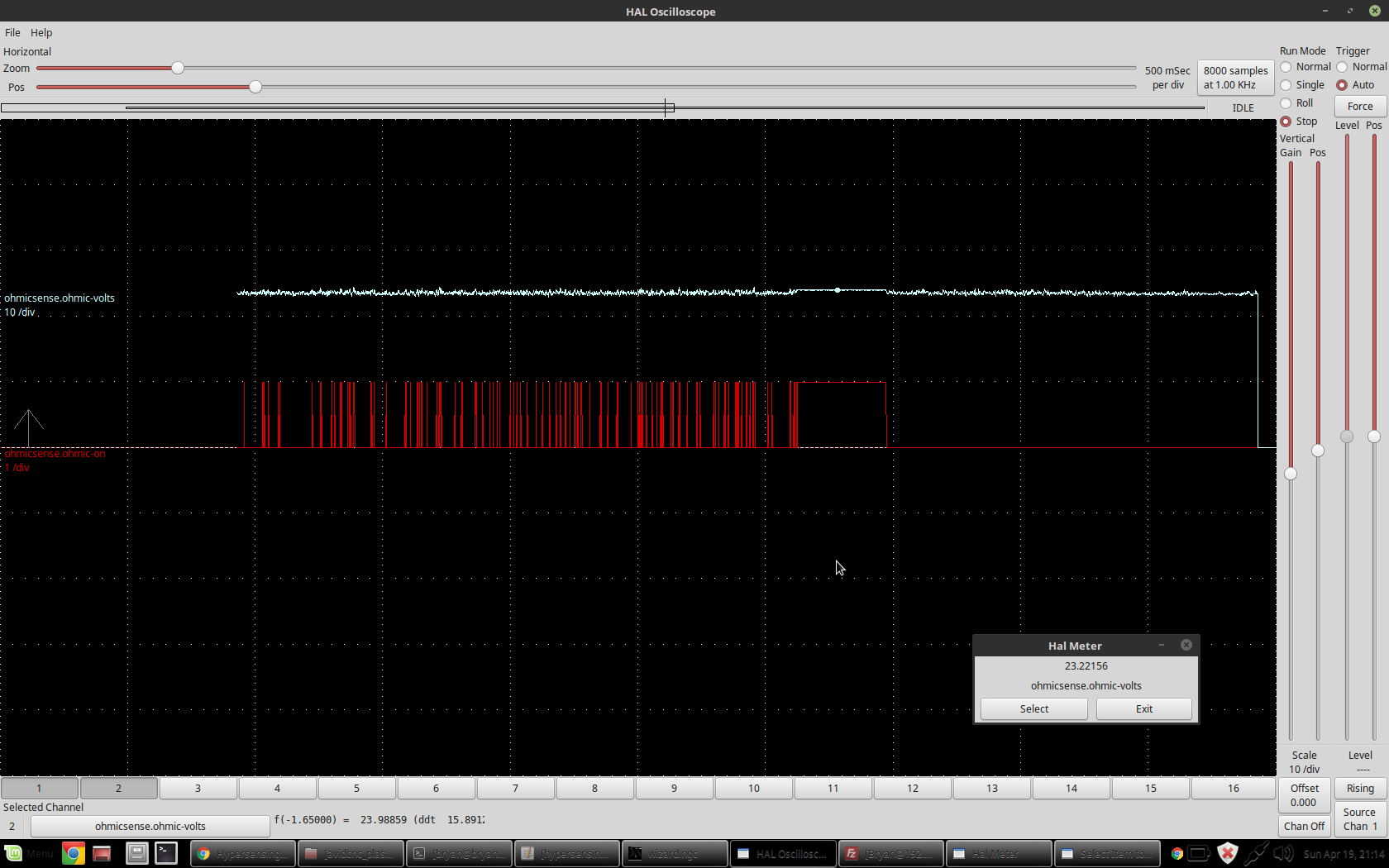

Before I test Rod's comp changes I figured I would add (temporarily) a 1/2W 22kOhm resistor and see what it does to the voltage when the torch is soaked. Proof is in the data

This is the baseline case. Lots of triggers. Using ohmic2.comp, but not quite the newest version with changing the ohmic threshold to look at argvolts.

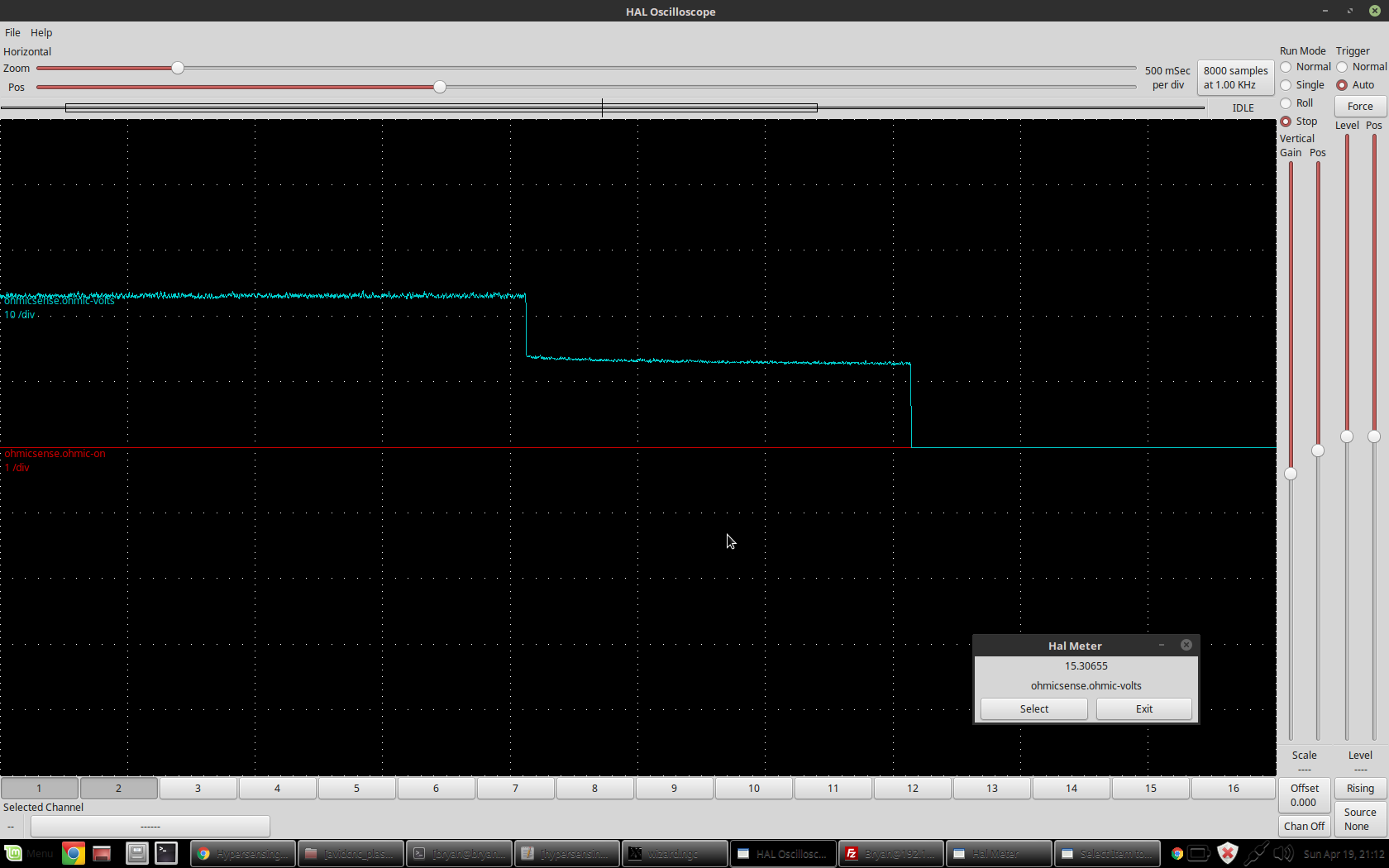

Then I added a 22kOhm 1/2W resistor between +24V and IN- (torch) and the voltage dropped quite significantly when not probing.

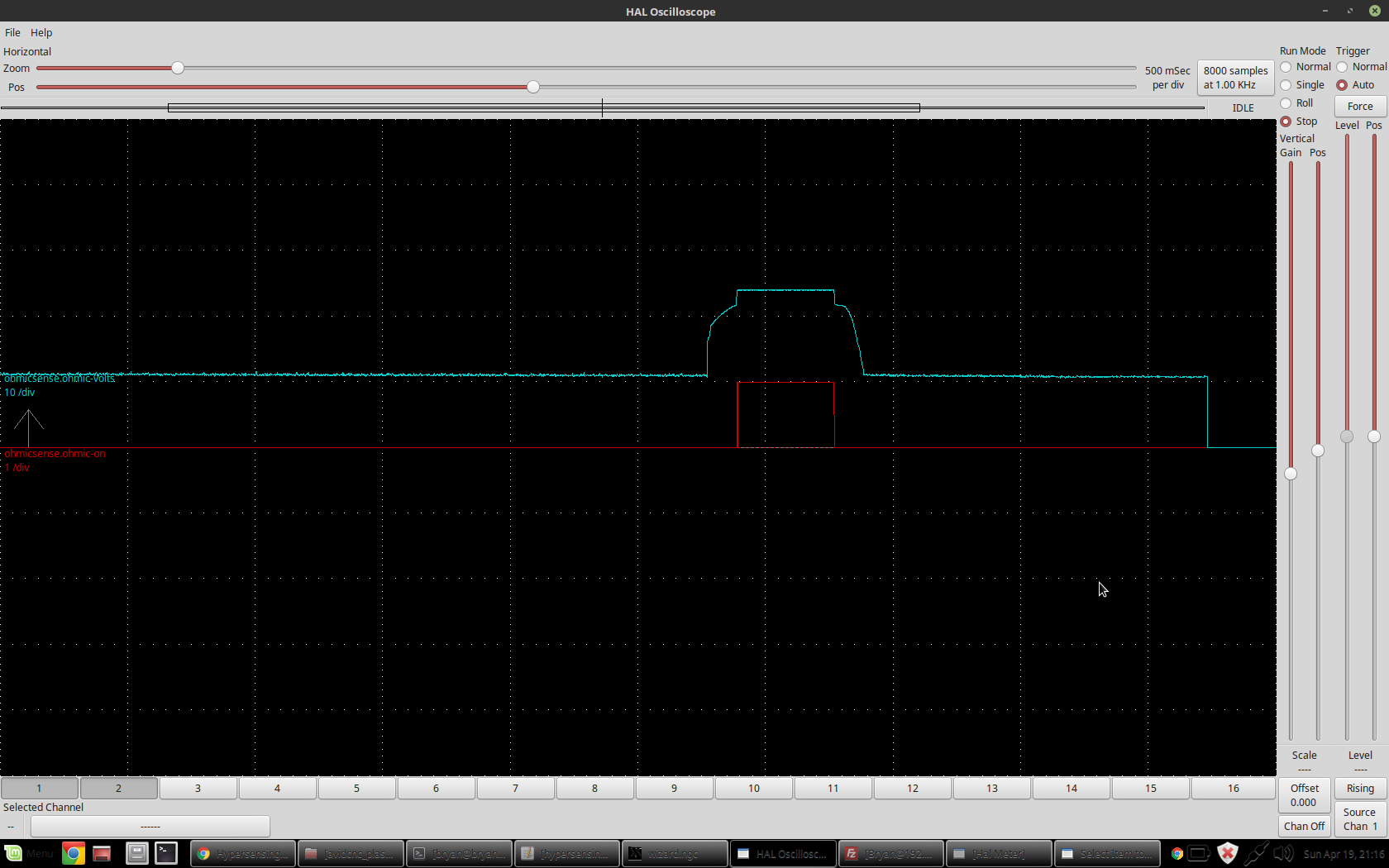

And here's a probe event with the 22kOhm resistor in place (torch was off the entire time!)

It seems as though the easiest fix is to add a 22kOhm 5W resistor between +24V and IN- as it still retains its ~24V sensitivity when contact is made, but drops to about 15-16V (from 23V) when the torch just has water in it. I obviously did not fire the torch in any of these cases as my resistor is not high enough wattage. We'll get to that in a few days.

I still plan on testing the comp changes that Rod suggested to see if a software fix works and is reliable. Should be able to post that data tomorrow.

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

It would take twice as much current to trip, in this case might be even better.[

Also, What would be the difference between a 10K 10W resistor mentioned previously and the 24K 5W resistor mentioned here?

Which is which?

10K 10W takes 2x as much current to trip

or

24K 5W takes twice as much current to trip?

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Turned off all power to everything. Plasma cutter still plugged into wall, but off. 24v isolated psu is unplugged Thcad-5 input and output connectors, unplugged Wire on cap, resistance between torch shield and table: infinite resistance (open circuit) Wire removed from cap, torch shield to table, resistance is still infinite as the circuit is open Work clamp removed from table, open circuit, infinite resistance (open curcuit) Plasma torch to work clamp resistance is 16.54K(I assume you mean from teh nozzle to the clamp

I dont see how it's possible you were getting 2.3M ohms with everything unplugged from the THCAD, unless you were touching the meter probes with your fingers. Otherwise, assuming everything was bone dry, there is literally no connection between the shield and the ground of the either the machine, or the table with the input and output disconnected from the THCAD.

Try this for me, remove your shield, exposing the nozzle, and measure from the nozzle to the ground clamp of the hypertherm. This is how I am getting 16.54K ohm.

Well I went and did the measurements again on a dry torch and got the same that you did. Open circuit, infinite resistance on all readings. It's possible I wasn't careful while measuring last time and was touching the probes. It's quite likely to be honest remembering how much it was varying, or it was with a wet torch? That's embarrassing.

Nozzle to work clamp I got 16.33Kohm. So that checks out.

Ok good! At least we have a solid baseline.

I havent had time today to do any work on the plasma, I was going to use a small wattage resistor as you did here, and not fire the torch. But I think that saves me some testing. Is there a reason you used 22K ohm over the suggested 24K by Peter?

For the hal scope tests you are doing, can you describe exactly what you are doing to test it? I want to make sure I can perform the same tests to reliably test what's going on. I am glad that the resistor takes the sensitivity to a wet torch down. That's a giant step in the right direction in my opinion.

I am still wondering... is that the use case Rod is trying to fix via code, or is he testing something else?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

I had to start the day with a couple of extra coffees to fill in time before heading off to Jaycar our local electronics outlet on my rounds to pick up parts. Even then I still had to wait a few minutes for them to open. That was a good thing because PCW's resistor calcs arrived while I was filling in time.

Jaycar did not have anything in 5W > 4.7k so I came a way with 5 x 4.7k 1 W resistors which in series should give me 23.5k at 5 Watts. I don't think it will matter much about the values used as long as they are in the ball park. The value selected is a bit dependent on your suppliers range of components as people like Jaycar do not keep the full range of available values.

In answer to your questions about the software, bear in mind I don't have a problem with probing here and I did not have any halscope plots of probing from you guys until today so I was a bit in the dark.

I think though the changes I've made to the component are probably worthwhile. Typically a relay would be used and they have a hysteresis setting and some of them are quite low. The ones I used turned on at 8 volts and off at 5 volts. Others such as the opto22's are 18 volts on and 1 volt off. So basically, I mimicked a relay with the first version. Bear in mind the critical part of probing is where the Z axis is backing off the material so that switch hysteresis needs to be taken up which could mean some additional travel before the "surface" height was recognised.

The theory I had was that by the time the torch stopped motion, it would have gone past the surface some distance (dependent on velocity and acceleration settings. So then it had to back up to the lower hysteresis to turn off. That could be 0.3-0.4mm higher than the surface. So if we tracked the voltage trend (is the voltage going up or down over time), we could turn the probe off well before the hysteresis would allow it previously. In effect I am depending on that overtravel to provide the hysteresis. I actually coded that. But then becasue of the noise I was seeing in your plots, instead of tracking the trend, I decided to use an existing algorithm that calculated a moving average for the ohmic volts. When you think about this, that achieves the same thing because the average of the last 5 readings has to be less than the trigger threshold.

So I hope this revised component proves robust becasue I think it will result in faster and more accurate probing...

I hope you guys realise that with PCW's help, we appear to have solved an age old problem and that is to allow robust and reliable ohmic sensing on water tables. Many people thought this was not possible as summed up in this recent post over the weekend on plasmaspider:

See: plasmaspider.com/viewtopic.php?f=3&t=30183I recently moved the table to my garage and made a water table for it. Ohmic sensing does not work on a water table with a Plasmacam despite what people say. The water continuously goes back into the nozzle and shorts it out causing a "torch hit material" error. The machine continues to blow air after it is done cutting and this causes water to spray up into the torch, shorting it out.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

Fire fire!

Please Log in or Create an account to join the conversation.

- snowgoer540

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

10Kohm = more current or less resistance more current passes through.

Fire fire!

Fire bad. Haha

I bought some 24K 5W and 10K 10W from Mouser. Be here Wednesday. More options for testing I figure.

Why not 24K 10W?

Please Log in or Create an account to join the conversation.