For PhillC regarding PlasmaC and Z axis stuff

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 08:25 #165502

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

I did not set G54 or any offsets. Maybe that removes the issue and that is a nice solution, and i will test that just after i get some coffee in me, as i have the test setup on the bench. And i do recall you mentioning to do a touch off. Back in a few.Yeah, I can't see any thing wrong at the moment.

I think it is a good idea to set your G54 position at the Z minimum, that way your DRO always shows the relative height above the Z minimum.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 09:01 #165510

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

Will do so, just doing some more tests.Could you post an ini file that plays up and I will have a look.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 09:54 #165516

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

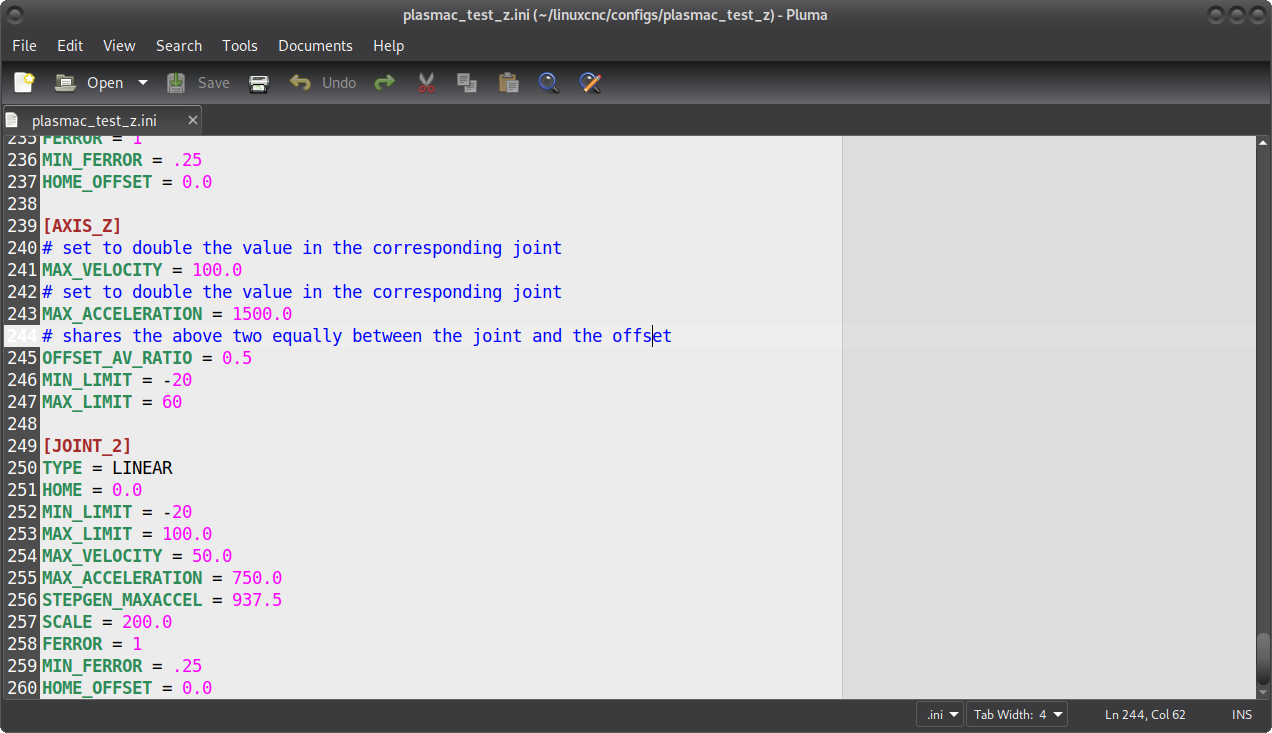

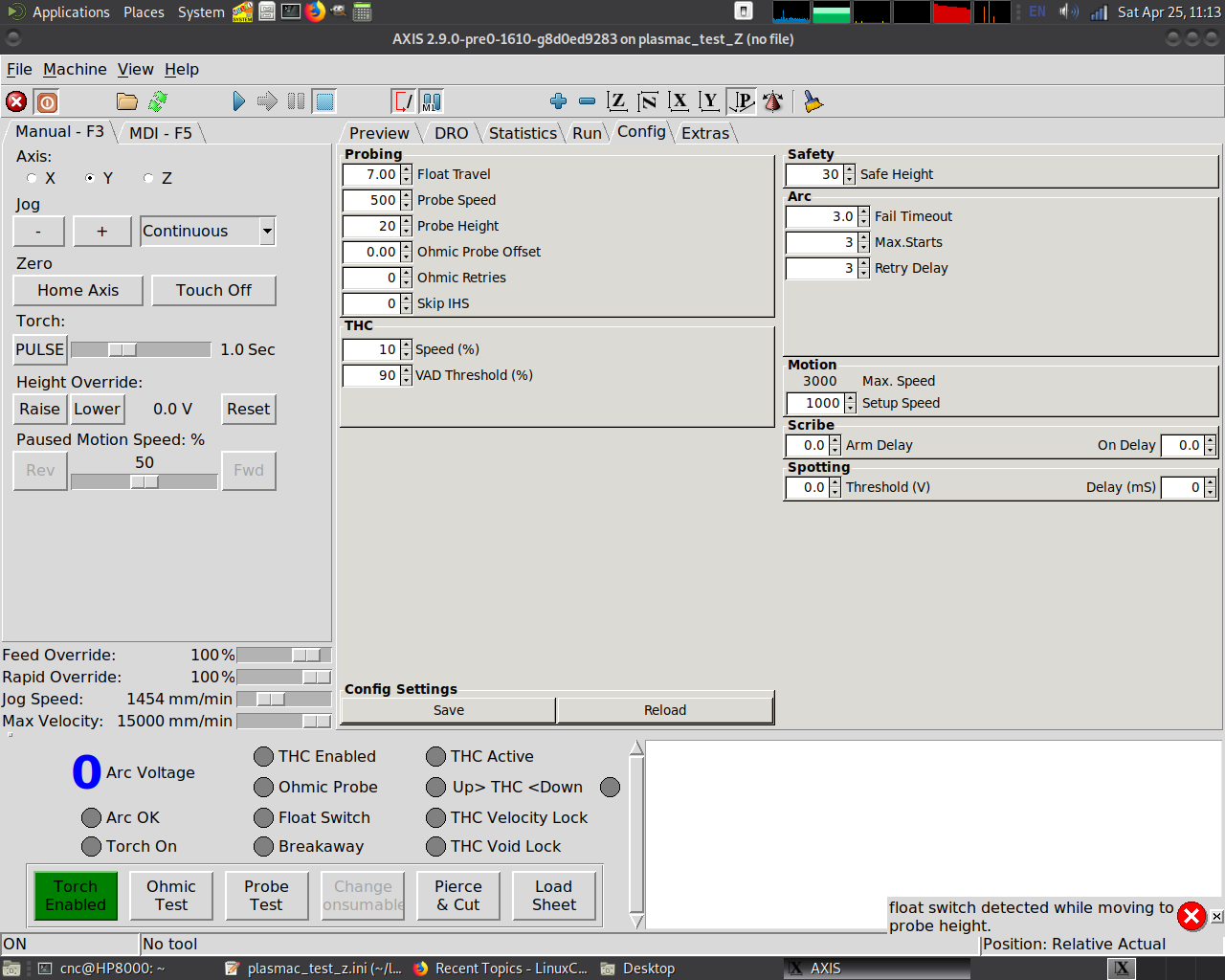

Linuxcnc 2.9 build 1610 :

No touch off !

Z axis ini settings: -20mm

Config panel settings: Probe height = 20 , safe height = 30

Result = Error on probe test.

Same ini, config settings changed to: probe height = 30, safe height = 45

Result with 3mm thick material = no error.

Result with 10mm thick material = error on probe.

Same ini, config settings changed to: probe height = 40, safe height = 50

Result with 10mm thick material = no error, safe traverse height has been reduced.

-

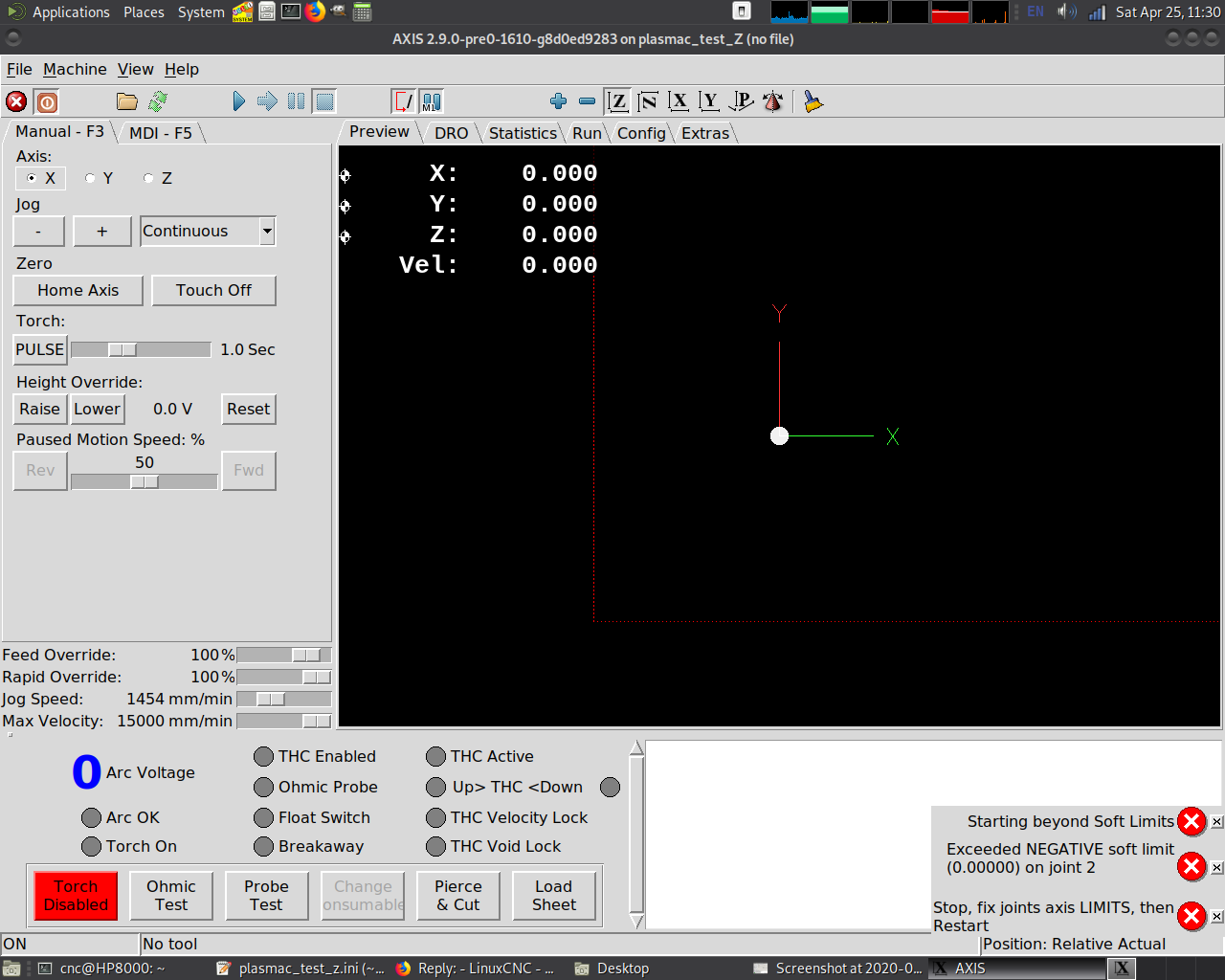

Set the min_limit to 0 for the Z axis, go to slats to home, press home, error :

To recover, press F1, then again F1 and F2.

If by any chance it gets to 0 value on the Z axis during jogging, it will trip limit error, notify about fixing limits and restart, so not motion is possible, a restart of Linuxcnc is required.

-

With touch off just above the 3mm material, ini min_limit at 0, config probe height at 20 and safe height at 35 = works OK.

With touch off just above the 10mm material, ini min_limit at 0, config probe height at 20 and safe height at 35 = works OK.

Unfortunately i can not reproduce an error i got twice last night where is would stop all motion, error out ( do not recall the exact error ) and a restart of Linuxcnc would be required.

No touch off !

Z axis ini settings: -20mm

Config panel settings: Probe height = 20 , safe height = 30

Result = Error on probe test.

Same ini, config settings changed to: probe height = 30, safe height = 45

Result with 3mm thick material = no error.

Result with 10mm thick material = error on probe.

Same ini, config settings changed to: probe height = 40, safe height = 50

Result with 10mm thick material = no error, safe traverse height has been reduced.

-

Set the min_limit to 0 for the Z axis, go to slats to home, press home, error :

To recover, press F1, then again F1 and F2.

If by any chance it gets to 0 value on the Z axis during jogging, it will trip limit error, notify about fixing limits and restart, so not motion is possible, a restart of Linuxcnc is required.

-

With touch off just above the 3mm material, ini min_limit at 0, config probe height at 20 and safe height at 35 = works OK.

With touch off just above the 10mm material, ini min_limit at 0, config probe height at 20 and safe height at 35 = works OK.

Unfortunately i can not reproduce an error i got twice last night where is would stop all motion, error out ( do not recall the exact error ) and a restart of Linuxcnc would be required.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 09:56 #165517

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

Attached is the config in zip form.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

25 Apr 2020 10:00 #165519

by phillc54

Replied by phillc54 on topic For PhillC regarding PlasmaC and Z axis stuff

Thanks Tom, I will digest all that tomorrow, I am digesting wine at the moment...

A quick look at the ini shows different values for the axis and joint max limits, I don't know if that causes any problems.

A quick look at the ini shows different values for the axis and joint max limits, I don't know if that causes any problems.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 10:22 #165523

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

Enjoy it !I am digesting wine at the moment...

I am aware, it does not get to 60mm ever while testing.A quick look at the ini shows different values for the axis and joint max limits, I don't know if that causes any problems.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

25 Apr 2020 10:42 #165524

by bbsr_5a

Replied by bbsr_5a on topic For PhillC regarding PlasmaC and Z axis stuff

i made a hard block ending at part Z height so it cand move deeper at all while the controll can go to table height

the Nema 17 at Z wont make a damage at blockend when thc likes to go down more just oversteps

the Nema 17 at Z wont make a damage at blockend when thc likes to go down more just oversteps

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

25 Apr 2020 10:42 #165525

by phillc54

Replied by phillc54 on topic For PhillC regarding PlasmaC and Z axis stuff

Some similar issues here to the other thread today ..

When you had z minimum at -20 do you know where the torch was in relation to the slats when you jogged z fully down.

I don't suppose you know what he original g54 offset was before you did the touchoff.

When you had z minimum at -20 do you know where the torch was in relation to the slats when you jogged z fully down.

Did you jog Z down for this.Set the min_limit to 0 for the Z axis, go to slats to home, press home, error :

I don't suppose you know what he original g54 offset was before you did the touchoff.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

25 Apr 2020 10:49 #165527

by bbsr_5a

Replied by bbsr_5a on topic For PhillC regarding PlasmaC and Z axis stuff

at some time i wars thinking of getting a user Mcode or nc file started on Reference finish

to set things intirer to the known behaviors

but it is there alredy as it touched the ref switches only the new Material omic sence does a new G54 z set and then i can start from the Sheetcam zero fixed to the mashine sheet zero place

to set things intirer to the known behaviors

but it is there alredy as it touched the ref switches only the new Material omic sence does a new G54 z set and then i can start from the Sheetcam zero fixed to the mashine sheet zero place

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

25 Apr 2020 11:09 #165530

by tommylight

Replied by tommylight on topic For PhillC regarding PlasmaC and Z axis stuff

Just a bit under the top of the slats, or table in this case, about 3mm.When you had z minimum at -20 do you know where the torch was in relation to the slats when you jogged z fully down.

Yes.Did you jog Z down for this.

No offset, machine 0 at G54 0.I don't suppose you know what he original g54 offset was before you did the touchoff.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.157 seconds