For PhillC regarding PlasmaC and Z axis stuff

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21061

- Thank you received: 7184

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I don't understnd this meassage, it comes from motion and there is no motion while probing, plasmac takes control.also says fix limits and restart

I have been probing this morning at 1200mm/min with no issues. I setup some feeler gauges and I can have a 0.01mm difference between a probe being successful or hitting the lower limit and it has consistently worked as intended.

This is so frustrating, would you believe the actual float travel I ended up with is 6.66mm. An apt number for these circumstances...

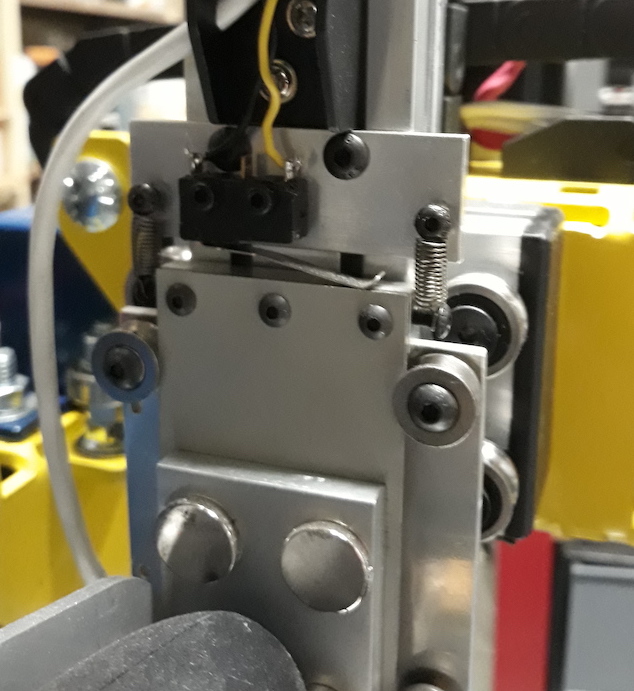

I thought I show my hi tech float switch on the little sherline mill.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

It shows the plasmac error "bottom limit reached while probe testing" then times out and recovers which is the expected behaviour.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21061

- Thank you received: 7184

LOL, happening quite often these days.This is so frustrating, would you believe the actual float travel I ended up with is 6.66mm. An apt number for these circumstances...

Nice setup.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

The Probe test button turns red when a probe test begins then the seconds count down on the button.

If it thinks it will hit the bottom limit it prints an error then imediately returns to the start position then restores the button to normal.

If you use Buildbot it may be a while before it builds the packages, it seems to be having a sleep.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21061

- Thank you received: 7184

That was regarding retraction speed, as you might have noticed on the screenshots on the vertical axis GUI topic, for 8 hours and 44 minutes of work time i had 3 hours and 55 minutes of probing time.If you needed to I could make a pin or parameter to adjust it with a HAL setp

Thank you.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I still have a problem understanding this.That was regarding retraction speed, as you might have noticed on the screenshots on the vertical axis GUI topic, for 8 hours and 44 minutes of work time i had 3 hours and 55 minutes of probing time.

Z goes down at Probe Speed (Config Panel).

Material sensed.

Z goes up at 0.001mm per period

Material not sensed - this is the zero point

Z moves up to Pierce Height at Setup Speed (Cconfig Panel)

The amount of Z motion up to turn the switch off should only be the switch hysteresis plus overrun.

I use a mechanical microswitch and it is somewhere around 0.25mm so about a quarter of a second of Z travel.

I see your Z accelleration is 750 and your probe speed is 500 so your overrun should be around 0.05mm, that is .05 seconds of Z travel.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11563

- Thank you received: 3882

Also I'd like the torch to go up to max height at the end of the job so that the torch is away from the water table and not splashing everywhere..... geez we are demanding bastards.....

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

- Posts: 21061

- Thank you received: 7184

-

I am using a different float setup on new machines, so the float has to travel 7mm to trip the switch + 2mm of overrun, them move up the full length plus pierce height, so that makes 12mm of retract travel on every probe. That can be clearly seen here:

forum.linuxcnc.org/show-your-stuff/38547...uild?start=60#167665

I can shorten the bolts that hold the floating part to about half, halving the probe time, without the need to slow down the Z axis.

At any rate, please do not worry about it.

Thank you very much for everything.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

That how I do my probing, my probe height is 1mm so it always hits first at the fast speed.I wonder if this should not be a bit like the home switches. Smash down fast, back up a bit slower till it breaks and then go down again at a slower speed till touch, then come back up at 0.001/period.

I have often thought about this as well. Unfortunately PlasmaC doesn't know about jobs, only cuts.Also I'd like the torch to go up to max height at the end of the job so that the torch is away from the water table and not splashing everywhere..... geez we are demanding bastards.....

Please Log in or Create an account to join the conversation.