Error Recovery

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

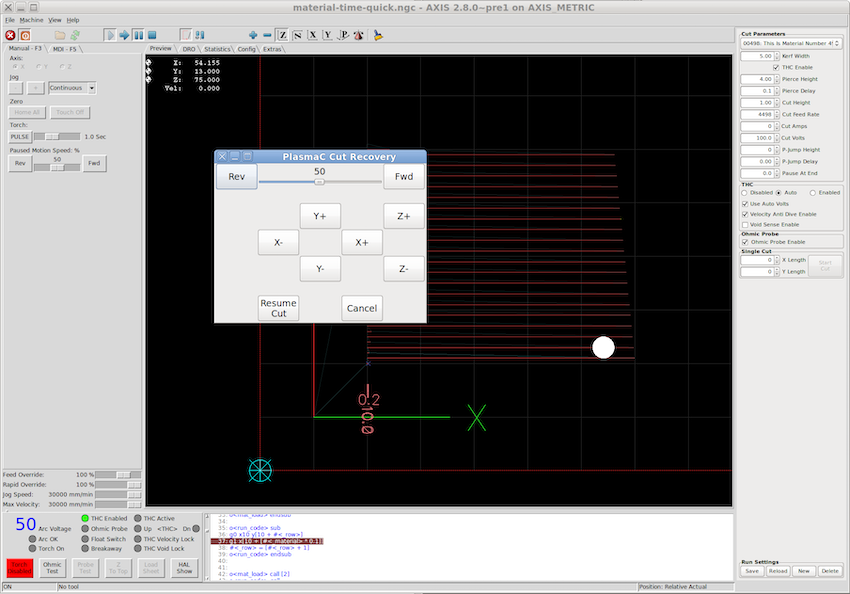

I am toying with this idea, basically the Paused Motion section in the GUI would be replaced with a single button labelled Cut Recovery that only shows when paused.

This button when pressed will bring up a recovery dialog as shown.

Then the operater can move in reverse or forward to an appropriate position on the cut, then use the X/Y buttons to move the torch to the waste side of the cut.

The Z button is just a convenience to allow the torch to be close to the material to make sighting a bit easier.

Each button press would offset by one kerf width as displayed in the cut parameters.

When a satisfactory starting point is reached then there are two options:

- Cancel in which case the the offsets are cleared and the dialog box closes.

- Resume Cut which will move X to the original height if required then start a cut at the current position then the torch will move to the the cut line at the position where the offsets were applied then continue on with the cut.

I am not 100% sure if this is feasible or even if it is a good idea so I thought I would put it out there for any comments.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11679

- Thank you received: 3936

I'm not sure its a good example to base enhancements off when Clive remade his holder after that cut.

The warpage was not really a lot and certainly not enough to trigger a stoppage on my machine. The THC should have managed it.

The most issues I've had with stoppages has been on probing and hopefully you have tamed the kangaroo.

It will be interesting to hear what others think.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21231

- Thank you received: 7249

Yup, on something that is never gona be looked at from near enough to actually see it.Don't you end up with a divot where the restart happpens.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

$Rod The warpage was not really a lot and certainly not enough to trigger a stoppage on my machine. The THC should have managed it.

It was the float switch that triggered the pause. I think with your plasma cutter you can cut at a higher height than me.

Re the divert, It is hardly noticeable . I have now change the torch mount to alli as I noticed the plastic one was not up for the job in keeping the torch perfectly in alignment, in fact it broke.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2532

- Thank you received: 864

I saw this video from Clive and thought that the must be a better option for error recovery to minimize divots on a cut recovery.

I am toying with this idea, basically the Paused Motion section in the GUI would be replaced with a single button labelled Cut Recovery that only shows when paused.

This button when pressed will bring up a recovery dialog as shown.

Then the operater can move in reverse or forward to an appropriate position on the cut, then use the X/Y buttons to move the torch to the waste side of the cut.

The Z button is just a convenience to allow the torch to be close to the material to make sighting a bit easier.

Each button press would offset by one kerf width as displayed in the cut parameters.

When a satisfactory starting point is reached then there are two options:

- Cancel in which case the the offsets are cleared and the dialog box closes.

- Resume Cut which will move X to the original height if required then start a cut at the current position then the torch will move to the the cut line at the position where the offsets were applied then continue on with the cut.

I am not 100% sure if this is feasible or even if it is a good idea so I thought I would put it out there for any comments.

So I like the premise of the idea, but I'm a bit fuzzy on the execution. A few questions:

1. Will the jog keys on the keyboard work, or will the user HAVE to use the buttons in the dialog box?

2. I'm confused as to why it's offset by one kerf width? If you move into the waste area, does it matter that it's offset? I'm not following here.

3. So, the idea is that I move the torch to an area where there's waste material, and when I press go, it's going to take the shortest path back to where it stopped when it paused? I'm wondering if that will still leave a divot? Any chance of a flame out if it crosses the kerf? I think leaving a little bump of material may be better than a divot, at least it's usually easier to grind those off.

4. This sounds a bit like something Tormach does for when the operator stops the program. It highlights last executed line. Then you can right click on that line and choose from a slew of options. See the attached pic from their 1100MX manual below. Just reminded me of that feature, and thought I'd share.

At any rate, it seems useful off the cuff. I'm all about anything that makes the end user's experience better.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

You would have to use the dialog box buttons. It may be possible to modify the existing buttons in Axis but I don't think it would be possible in Gmoccapy. I like to keep both the same if possible as it is a PITA supporting two GUIs.1. Will the jog keys on the keyboard work, or will the user HAVE to use the buttons in the dialog box?

Well you need to set the amount you offset so I figured that would be a good starting point plus there is no units specific code. If you want to move X three kerf widths positive you press X+ three times.2. I'm confused as to why it's offset by one kerf width? If you move into the waste area, does it matter that it's offset? I'm not following here.

Yes, it probes, starts the cut and moves in a straight line to were the offset started from then continues the original cut.3. So, the idea is that I move the torch to an area where there's waste material, and when I press go, it's going to take the shortest path back to where it stopped when it paused?

The idea is that with some practice you could find the place where you don't, you can use the Fwd/Rev of Paused motion to set the start point of the cut then set the offset you want.I'm wondering if that will still leave a divot?

I don't know, my machine is in permanent CPA mode so I don't see that.Any chance of a flame out if it crosses the kerf?

I agree.I think leaving a little bump of material may be better than a divot, at least it's usually easier to grind those off.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2532

- Thank you received: 864

Ah, ok that make sense. I wasnt tracking that each button click moved you a predetermined amount. That sounds better to me, and makes my angst over not being able to use the keyboard lessen.Well you need to set the amount you offset so I figured that would be a good starting point plus there is no units specific code. If you want to move X three kerf widths positive you press X+ three times.

Holy crap! Why didn't I ever think of that?! This is brilliant lol. Consider mine permanently in CPA now too.I don't know, my machine is in permanent CPA mode so I don't see that.

Well, you know I'd be happy to test it and break it for you

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Mine is a Powermax 30XP so there is only one mode.Holy crap! Why didn't I ever think of that?! This is brilliant lol. Consider mine permanently in CPA now too.

I thought I would do something different for a change and give this one a test myself.Well, you know I'd be happy to test it and break it for you

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2532

- Thank you received: 864

I thought I would do something different for a change and give this one a test myself.

Well... where's the fun in that?!

Please Log in or Create an account to join the conversation.