Sheetcam and trying to generate spotting gcode.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

I read the thread on the sheetcam forum and saw that my pp is wrong so to cover my butt I have removed it.

Funny that you've been wrong all these years and your PP has worked perfectly for me all that time.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- LesNewell

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 22

One thing I noticed:

Line #161: I believe begin cut gcode should be M3 $0 S1

Yes, you are correct. I'll fix it.

I've been farting around with sheetcam trying to find an answer to my previous question. If the pp has any DefineCustomToolParam lines then sheetcam will add input boxes for these lines in the tool dialog box after sheetcam sees these params in the pp (either when loading or after running the pp) Does that all sound correct?

Yes. To enable the pmx485 options you need to set pmx485 to true. If you are modifying the post for your own purposes you can use DefineCustomToolParam to add your own parameters. You can also use DefineCustomToolParam to add parameters to your plasma operations. Instead of 'PlasmaTool' you'd use 'JetOperation'.

Or was another thread started that I overlooked?

No, this is the correct thread. If you want to add extra functionality, now is a good time to discuss it.

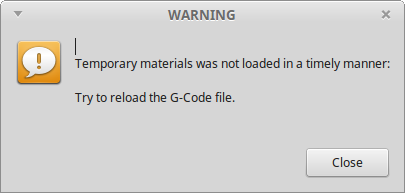

I got an error loading the magic comment version about it taking too long. But I don't think thats a post issue.

Does this have anything to do with M66 P3 L3 Q2? The magic comment version does not use this.

Also, the Pause at end of cut variable doesn't appear to do anything.

The magic comment appears to be correct. Just a thought - is the delay in seconds or milliseconds? I used seconds.

Does end delay work if you use the Plasmac material table?

Funny that you've been wrong all these years and your PP has worked perfectly for me all that time.

Welcome to my world. This sort of thing happens surprisingly often. Bugs that need a slightly unusual set of circumstances to show up can stay hidden for years. Another problem is that quite often when people hit issues like this, they find a workaround rather than reporting it.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

[

I got an error loading the magic comment version about it taking too long. But I don't think thats a post issue.

Does this have anything to do with M66 P3 L3 Q2? The magic comment version does not use this.

Possibly but I don't think so as my guess is the magic comments are parsed in the python filter that processes the gcode.

When Gcode communicates with plasmac non-real time components (Like the feed rate), it does a M66 and waits for Plasmac to acknowledge the tool change. Because it uses a sequential search, with a lot of tools, I found I had to increase the Q parameter or it timed out in a similar way.

In fact, use of the feedrate pin was a kludge because Linuxcnc's motion controller had no knowledge of the feedrate set in gcode at run time so there was no reference velocity available for velocity antidive. In v2.9 with the inclusion of state tags, the motion.feed-upm pin (ref linuxcnc.org/docs/devel/html/man/man9/motion.9.html) could be used for VAD if Plasmac altered its behaviour. If this change was done in Plasmac, sheetcam could set the feedrate itself which would be much more efficient.

Pehaps you could convince Phill to make this change in V 2.9

Please Log in or Create an account to join the conversation.

- LesNewell

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 22

I don't have any problem with having to specify the feed rate in a magic comment. In fact it's useful if you use path rules to override the feed rate. Overriding the feed rate currently also disables THC. If motion.feed-upm was used this would not happen. Of course you can make the rule explicitly turn THC off and back on so it's no big deal either way.In v2.9 with the inclusion of state tags, the motion.feed-upm pin (ref linuxcnc.org/docs/devel/html/man/man9/motion.9.html) could be used for VAD if Plasmac altered its behaviour. If this change was done in Plasmac, sheetcam could set the feedrate itself which would be much more efficient.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

- Posts: 339

- Thank you received: 96

Also, the Pause at end of cut variable doesn't appear to do anything.

The magic comment appears to be correct. Just a thought - is the delay in seconds or milliseconds? I used seconds.

Does end delay work if you use the Plasmac material table?

Disregard my comments in regard to endDelay. I was looking for G4 in the gcode rather than relying on plasmac to take care of this.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I found the result from when we tested this some time back, with 500 materials the maximum time to change was 0.16 seconds. I don't "think" anything has changed in the meantime.[When Gcode communicates with plasmac non-real time components (Like the feed rate), it does a M66 and waits for Plasmac to acknowledge the tool change. Because it uses a sequential search, with a lot of tools, I found I had to increase the Q parameter or it timed out in a similar way.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11624

- Thank you received: 3913

I found the result from when we tested this some time back, with 500 materials the maximum time to change was 0.16 seconds. I don't "think" anything has changed in the meantime.

This is the error I'm getting on loading the file with magic comments

Using the post above

which does:

;begin material setup

T0 M6 (select plasma tool)

G43 H0 (apply tool offsets)

(o=0, ph=4.1, pd=0, ch=4.1, fr=100, pe=0.5)

F#<_hal[plasmac.cut-feed-rate]>

;end material setupPlease Log in or Create an account to join the conversation.