Sheetcam and trying to generate spotting gcode.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Apr 2021 03:38 #207349

by phillc54

Replied by phillc54 on topic Sheetcam and trying to generate spotting gcode.

PlasmaC or QtPlasmaC

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

29 Apr 2021 03:43 #207350

by rodw

Replied by rodw on topic Sheetcam and trying to generate spotting gcode.

Plasmac. Will upgrade when I have a bit of spare time...

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Apr 2021 03:48 #207351

by phillc54

Replied by phillc54 on topic Sheetcam and trying to generate spotting gcode.

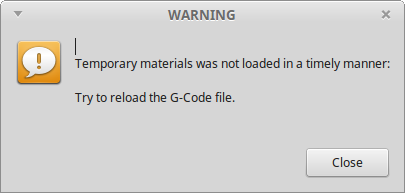

Hmm, that is weird, I have no issue in PlasmaC but I get that error in QtPlasmac. I can see what is happening/ not happening but I am not sure why.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 Apr 2021 04:56 #207353

by phillc54

Replied by phillc54 on topic Sheetcam and trying to generate spotting gcode.

You are attemting to use two temporay materials in this file which doesn't work, only the last one will be used.

linuxcnc.org/docs/devel/html/plasma/plas....html#magic-comments

It seems to fall over because it reads the gcode file quicker than it can create the temporary materials, I think it needs to be reversed and only use the first one then give an error popup if it sees any more.

This works around the timing issue if you want to try it. In /configs/by_machine/plasmac/plasmc_gcode.py there is a function:

def write_temp_default_material(data):

add this as the first line:

time.sleep(0.25)

linuxcnc.org/docs/devel/html/plasma/plas....html#magic-comments

It seems to fall over because it reads the gcode file quicker than it can create the temporary materials, I think it needs to be reversed and only use the first one then give an error popup if it sees any more.

This works around the timing issue if you want to try it. In /configs/by_machine/plasmac/plasmc_gcode.py there is a function:

def write_temp_default_material(data):

add this as the first line:

time.sleep(0.25)

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

02 May 2021 18:03 #207660

by snowgoer540

In the attached file, there are two different material magic comments in the same cut file.

I am curious, why would you want to have two different materials in the same cut file?

Just intrigued what the use case is for this.

Replied by snowgoer540 on topic Sheetcam and trying to generate spotting gcode.

I found the result from when we tested this some time back, with 500 materials the maximum time to change was 0.16 seconds. I don't "think" anything has changed in the meantime.

This is the error I'm getting on loading the file with magic comments

Using the post above

which does:;begin material setup T0 M6 (select plasma tool) G43 H0 (apply tool offsets) (o=0, ph=4.1, pd=0, ch=4.1, fr=100, pe=0.5) F#<_hal[plasmac.cut-feed-rate]> ;end material setup

In the attached file, there are two different material magic comments in the same cut file.

I am curious, why would you want to have two different materials in the same cut file?

Just intrigued what the use case is for this.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

02 May 2021 18:09 #207662

by rodw

Because one is a drilling operation for spotting on one layer and the other is a jet tool for plasma cutting.

Sheetcam loads a tool for each operation.

Replied by rodw on topic Sheetcam and trying to generate spotting gcode.

In the attached file, there are two different material magic comments in the same cut file.

I am curious, why would you want to have two different materials in the same cut file?

Just intrigued what the use case is for this.

Because one is a drilling operation for spotting on one layer and the other is a jet tool for plasma cutting.

Sheetcam loads a tool for each operation.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

02 May 2021 18:18 #207664

by snowgoer540

Using magic comments?

Replied by snowgoer540 on topic Sheetcam and trying to generate spotting gcode.

In the attached file, there are two different material magic comments in the same cut file.

I am curious, why would you want to have two different materials in the same cut file?

Just intrigued what the use case is for this.

Because one is a drilling operation for spotting on one layer and the other is a jet tool for plasma cutting.

Sheetcam loads a tool for each operation.

Using magic comments?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

02 May 2021 18:57 #207668

by rodw

Replied by rodw on topic Sheetcam and trying to generate spotting gcode.

Well no cos it would not load as above.

But yes, that was the whole point as magic comments will let Sheetcam be the master of the materials with Les's post..

I think that would be expected behaviour from the post processor on a tool change for the second operation.

I didn't write the code, Les did!

But yes, that was the whole point as magic comments will let Sheetcam be the master of the materials with Les's post..

I think that would be expected behaviour from the post processor on a tool change for the second operation.

I didn't write the code, Les did!

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

02 May 2021 19:25 #207670

by snowgoer540

I just didnt know because I never use that work flow. All my tools, etc. are already defined in sheetcam.

Replied by snowgoer540 on topic Sheetcam and trying to generate spotting gcode.

Well no cos it would not load as above.

But yes, that was the whole point as magic comments will let Sheetcam be the master of the materials with Les's post..

I think that would be expected behaviour from the post processor on a tool change for the second operation.

I didn't write the code, Les did!

I just didnt know because I never use that work flow. All my tools, etc. are already defined in sheetcam.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3913

03 May 2021 00:35 #207694

by rodw

Replied by rodw on topic Sheetcam and trying to generate spotting gcode.

I just didnt know because I never use that work flow. All my tools, etc. are already defined in sheetcam.

Yes me too, but I was testing Les's new post processor in this thread that allows Sheetcam to send its tool info direct to Plasmac which avoids any issues where the plasmac and shhetcam settings are not the same.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.142 seconds