Another GUI project underway

- workaholic

-

- Offline

- New Member

-

- Posts: 7

- Thank you received: 3

To be honest I'm new in this world of Linux CNC and I have started exploring it.

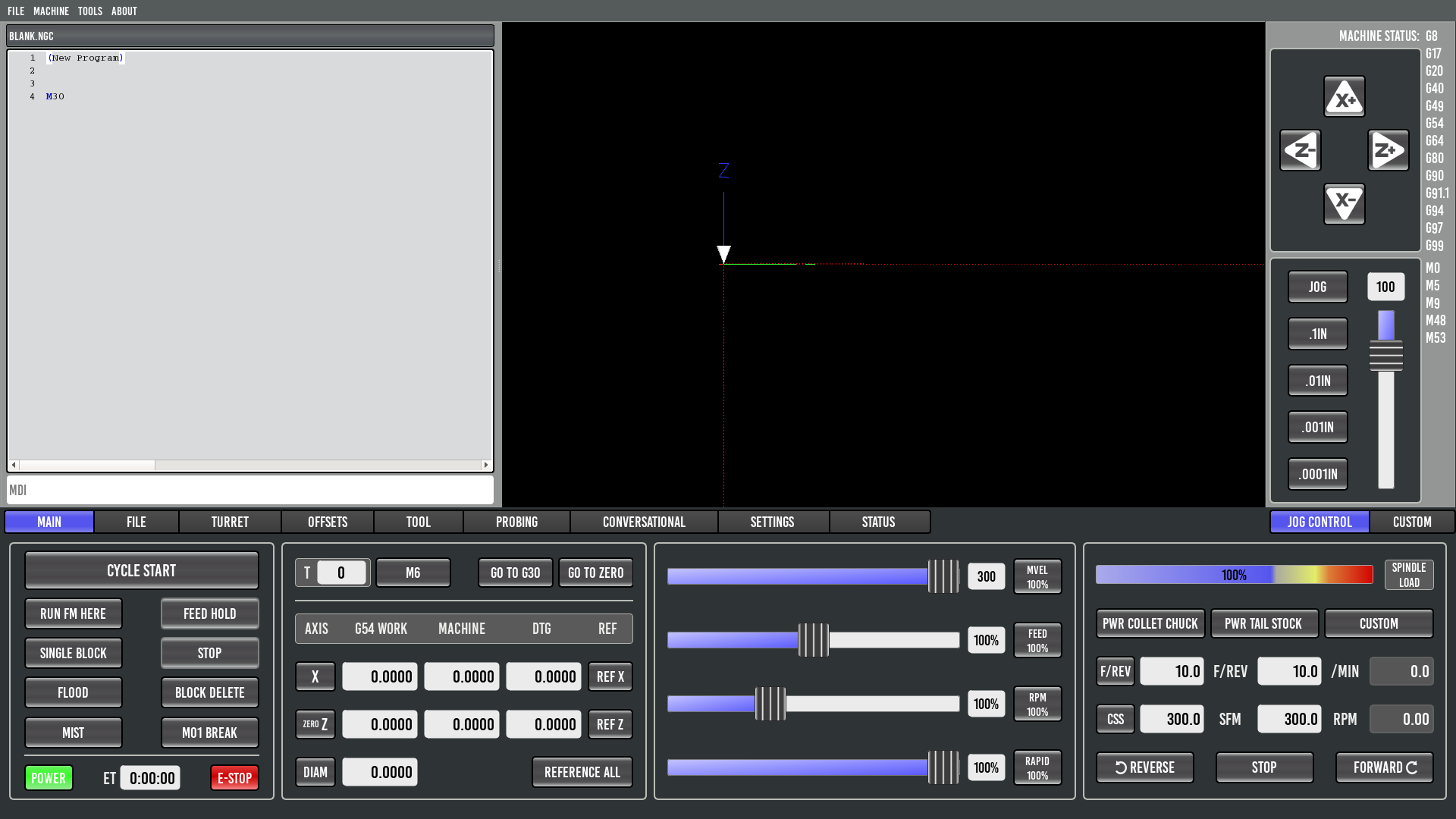

The concept which I'm working on and showing in my topic it's very friendly to users which are using touchscreens.

Link to my topic so you can see example image and description of my idea.

Preview plot - zoom to fit

I'm sorry for this reply being little off topic.

But maybe it would be nice to see that function in here if I or any other one will successfully made it.

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 1540

- Thank you received: 726

Please Log in or Create an account to join the conversation.

- Chich2

- Offline

- New Member

-

- Posts: 8

- Thank you received: 8

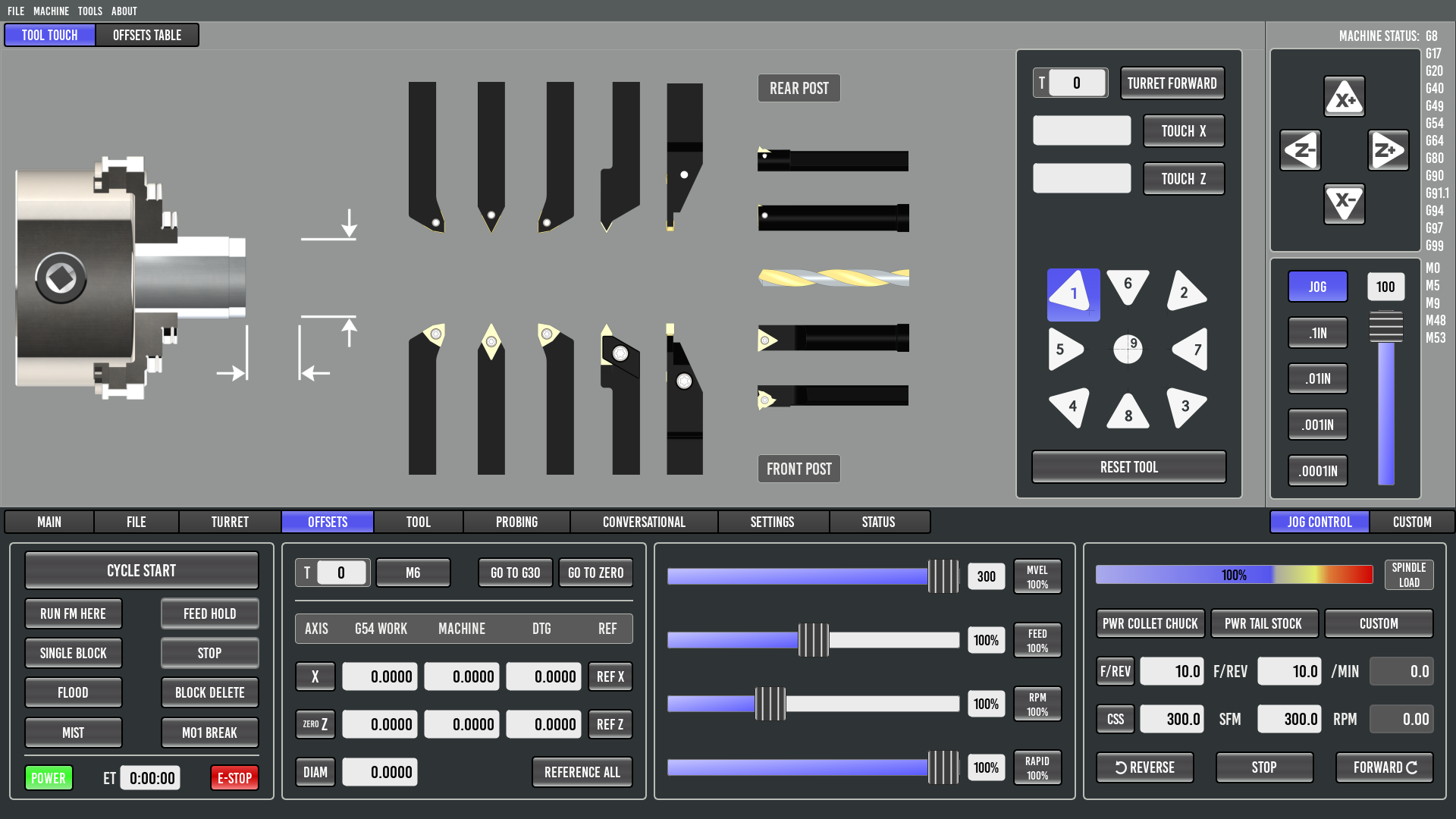

Your cnc lathe screen is a fantastic start. Some things to consider for the main screen that my lathe has:

My lathe has seperate buttons for tailstock quill in and out. A single button for the tool setter probe. Chip conveyor forwards and reverse buttons. I also have a 2 speed gear box driving my spindle that has a high and low speed buttons which are also selectable via M-codes during a program. A parts catcher button would be great also.

A little off topic issue i have is I would like to explain something about true cnc lathes and mills. When something goes wrong like a tool change doesn't mechanically complete correctly e.g. the tool change routine stalls half way through the routine for many reasons, there has to be a way to recover from the uncontrolled stop. Is there consideration in the GUI for a screen to manually force i/o?

Also I have personally seen a touchscreen become triggered by a fly running into it (Yes an insect hitting the screen) I would dread the thought of me being in my lathe or mill and a fly hitting cycle start or zero home all axis. You may laugh but Ive seen it happen on touch screens and you dont get a second chance with machinery.

I cant wait to see the final release of your awesome GUI. I hope my rambling is interpreted as only positive remarks and dont come across as negative. Please keep up the momentum and excellent regular updates.

Im sure we all appreciate your efforts,

Chich.

Please Log in or Create an account to join the conversation.

- KCJ

-

- Offline

- Moderator

-

- Posts: 328

- Thank you received: 267

I have personally seen a touchscreen become triggered by a fly running into it

Inadvertent triggering of a touchscreen is a very valid concern. I was using compressed air to clear chips when a droplet of coolant hit my touchscreen and aborted the program. It was a pain, but the best possible thing that could have happened.

Proper touchscreen selection should go a long way to preventing such mishaps. The resistive wire type screens require force to trigger, so won't be erroneously triggered by water droplets and the like. The capacitive (like on a phone) and SAW (ELO Intelitouch, what I have) are nicer to use but I've learned are not good for any critical applications!

I also don't use or recommend any sort of on-screen (or even keyboard) jogging - I had key stick and it was a bit panicky for a few seconds. Now I only use an MPG wired directly into the mesa card.

But there are also a lot of people here running routers and other light machines, where the consequences are small don't have the luxury of physical knobs and switches (Aaron Tippin voice

Cheers,

Kurt

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 1540

- Thank you received: 726

My lathe has seperate buttons for tailstock quill in and out. A single button for the tool setter probe. Chip conveyor forwards and reverse buttons. I also have a 2 speed gear box driving my spindle that has a high and low speed buttons which are also selectable via M-codes during a program. A parts catcher button would be great also.

For the tailstock buttons, does it require you to hold themfor movement or is it automatic? I have not worked with a power tailstock before so i don't know. I envisioned it being somewhat automatic based on pressure set etc? clue me in so i better understand the process flow.

gearbox is a good call, forgot all about that! probably also need a readout for what gear or pulley etc it is set on.

conveyor/auger, parts catcher etc I would consider all auxilliary functions and would be in the customized buttons area probably, can add a side bar for those.

Is there consideration in the GUI for a screen to manually force i/o

This will depend on how the turret control is setup by the end user in regards to wiring and control. there are many different turret types to make work so that is built into your configuration file and has less to do with the ui. if an M6 remap is used for example like on a mill atc or similar, then subroutines are used and inside the subroutines are a series of smaller sub routines that account for each move made by the atc process which can be manually commanded from inside the mdi. in the mill there is a manual atc panel to perform many of those individual operations. you will need to familiarize yourself with linuxcnc more to better understand the other options you have of controlling the atc or turret. there is also hal ladder which uses ladder logic for control. i am less familiar with that method as i have not used it but it functions similar to how a conventional machines tool change would and works with a series of inputs so it shouldn't be difficult to configure buttons to perform outputs to trigger those functions but that would require the end user to set everything up.

As for a fly on a touchscreen, well things happen. if you are building your own machine or retrofitting it, you should use caution and safety and utilize the ability of linuxcnc and mesa to have more inputs and outputs than one could ever probably truly use and install safety interlocks on the doors which would eliminate any possible accidents from occurring with the doors open where an operator may be able to put themselves in harms way, but again that falls on the end user as no one here can oversee what people do with the software or the interface once downloaded. so use common sense and read safety manuals online for other machines or retain all safeties on your current machine if retrofitting, they are easy enough to wire into linuxcnc and give priority too.

thanks for the input it is very much appreciated! I will put it to good use!

Chris

Please Log in or Create an account to join the conversation.

- KCJ

-

- Offline

- Moderator

-

- Posts: 328

- Thank you received: 267

Oh, and Merry Christmas!

Kurt

Please Log in or Create an account to join the conversation.

- mclausen

- Offline

- Senior Member

-

- Posts: 43

- Thank you received: 1

I have retrofit Hardinge lathe that I would like to use this on, and plans to retrofit two Kitamura mills in the future.

I used a lot of physical buttons and dials on my retrofit because it is nice to not have to look at the screen when running a new program, and have a finger on the HOLD button, or adjust the FEED OVERRIDE.

The touchscreen on my lathe is not a wide screen. Will it be easy to change the aspect ratio with this interface?

I have never run a factory CNC lathe, but to me it made sense to have the counter-clockwise spindle start to be the forward so that is how I made my control. What is the standard way? On a mill you are looking at the spindle from above, so forward appears clockwise. On a lathe you are looking at the spindle from the end so forward appears counter-clockwise.

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 1540

- Thank you received: 726

Exciting to see the progress on this interface! Thank you guys for all the hard work.

I have retrofit Hardinge lathe that I would like to use this on, and plans to retrofit two Kitamura mills in the future.

I used a lot of physical buttons and dials on my retrofit because it is nice to not have to look at the screen when running a new program, and have a finger on the HOLD button, or adjust the FEED OVERRIDE.

The touchscreen on my lathe is not a wide screen. Will it be easy to change the aspect ratio with this interface?

I have never run a factory CNC lathe, but to me it made sense to have the counter-clockwise spindle start to be the forward so that is how I made my control. What is the standard way? On a mill you are looking at the spindle from above, so forward appears clockwise. On a lathe you are looking at the spindle from the end so forward appears counter-clockwise.

the aspect ration for this particular screen will be for 1920x1080 screens, but once everything is finished on the big screens, I will probably go back through and make a small version for box screens as well. I also have a couple small box type touch screens so would be nice to have something that works for them. however given the space limitations that restricts, some buttons may not be on the main screen or the layout may change slightly and not be as open and free. will have to see what I can do when the time comes, but for now I am trying to finish the wide screen versions as they encompass more functionality and it is always easier to go smaller and remove functionality than it is to add it in.

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 1540

- Thank you received: 726

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

JT

Please Log in or Create an account to join the conversation.