Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

15 Jul 2018 09:09 #114205

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I've been pretty busy and have not done much on my plasma for a long time. I got a bit disillusioned after I blew up my THCAD card and the encoder input but PCW kindly built new firmware that put the encoder A on the undamaged Encoder B input on my 7i76e. I've been doing a fair bit behind the scenes with a couple of others. I finally seem to have got a reliable torch voltage signal coming from the plasma cutter.

I've also captured a lot of torch data for analysis and have a much greater understanding of arc behaviour. I also now know that my plasma cutter arc voltage changes by 7.53 volts per mm with 99.5% confidence after analysing 9000 readings.

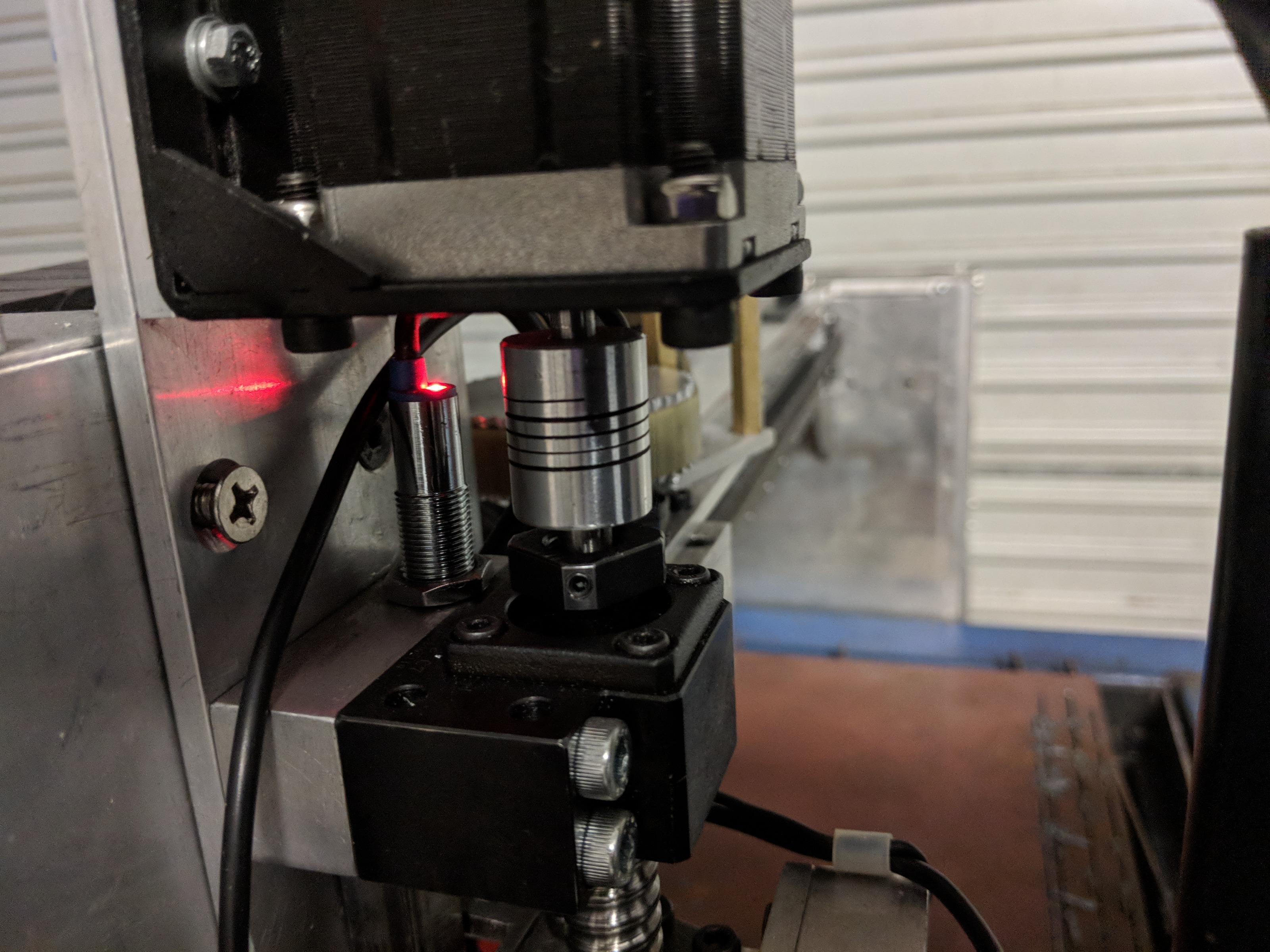

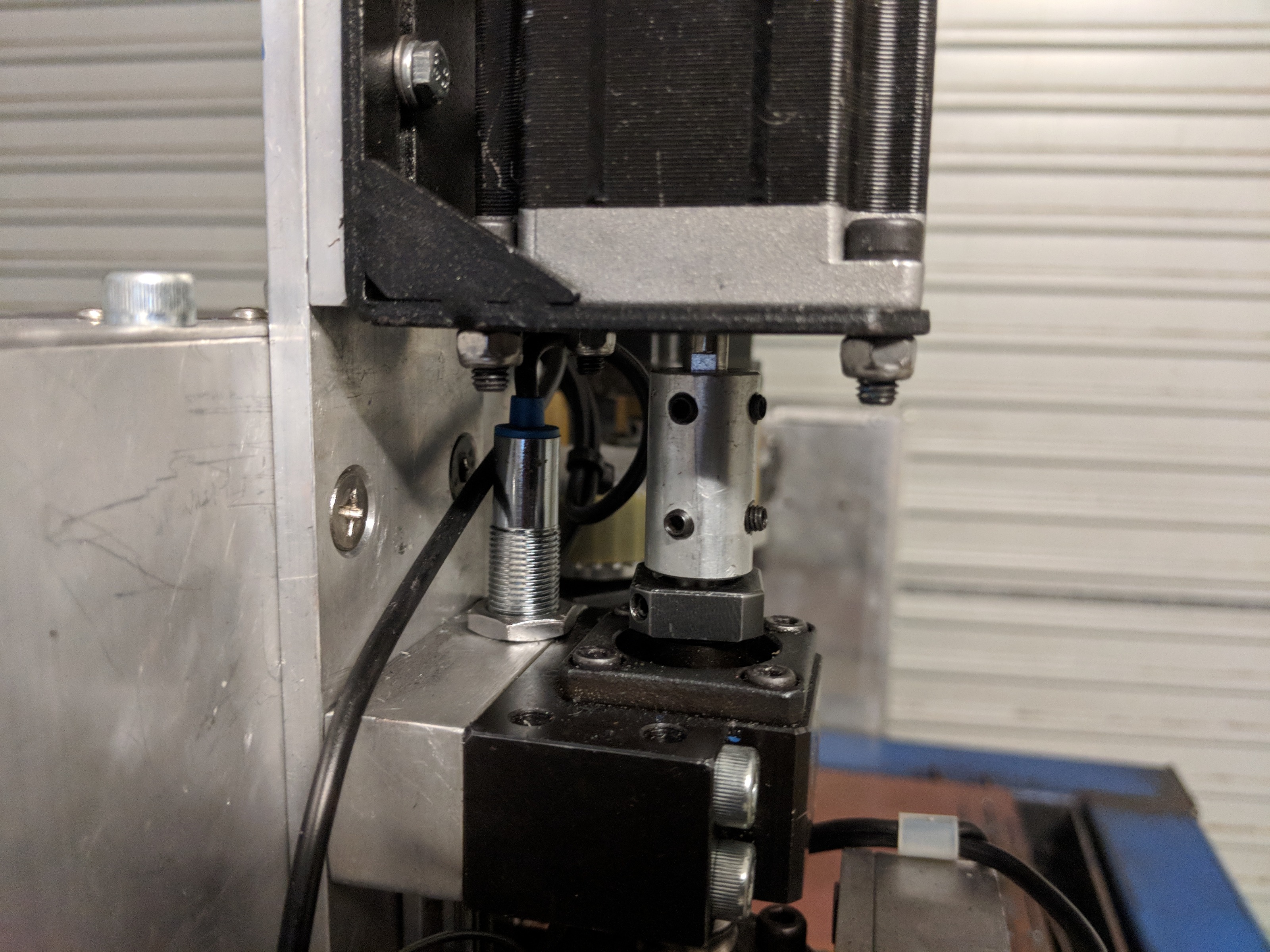

I said on another thread I'd give the external offsets thread one more go and yesterday I did about 70 cuts and still did not get a result. I said to myself that was it and then noticed that I could move the Z axis ball screw by hand while the motor was locked due to backlash in the helix misalignment shaft connector I had used.

So today, I decided to make a rigid connector and installed it.

But I still can't get it nicely aligned and its binding so I have had to reduce the the velocity by 25% to get it to work which is not ideal.

So I'm in the market for a zero backlash misalignment coupling like an Oldham coupling or something. If anybody has any ideas on what to buy, please let me know.

I can't do any more test cuts becasue tuning the plasma has been pretty hard on the torch so I've smashed the ceramic protector on the tip so I'm waiting for some to arrive which I ordered over the weekend.

I've also captured a lot of torch data for analysis and have a much greater understanding of arc behaviour. I also now know that my plasma cutter arc voltage changes by 7.53 volts per mm with 99.5% confidence after analysing 9000 readings.

I said on another thread I'd give the external offsets thread one more go and yesterday I did about 70 cuts and still did not get a result. I said to myself that was it and then noticed that I could move the Z axis ball screw by hand while the motor was locked due to backlash in the helix misalignment shaft connector I had used.

So today, I decided to make a rigid connector and installed it.

But I still can't get it nicely aligned and its binding so I have had to reduce the the velocity by 25% to get it to work which is not ideal.

So I'm in the market for a zero backlash misalignment coupling like an Oldham coupling or something. If anybody has any ideas on what to buy, please let me know.

I can't do any more test cuts becasue tuning the plasma has been pretty hard on the torch so I've smashed the ceramic protector on the tip so I'm waiting for some to arrive which I ordered over the weekend.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

15 Jul 2018 12:52 #114213

by robertspark

Replied by robertspark on topic Rods "Spaceship" Scratch built Plasma Cutter build

Ron I'm using one of these couplings

www.google.co.uk/search?client=ms-androi...imgrc=onk1ZFCeksBUQM:

I'd be interested in buying some of your data (it's obviously cost you a bit in materials and damaged parts to get)

I'd like to look at calculating not only the volts per mm but also the variance in the data and standard deviation which may also allow standard deviation which may be used for something like a kalman filter or complementary filter to estimate the predicted next sample

www.google.co.uk/search?client=ms-androi...imgrc=onk1ZFCeksBUQM:

I'd be interested in buying some of your data (it's obviously cost you a bit in materials and damaged parts to get)

I'd like to look at calculating not only the volts per mm but also the variance in the data and standard deviation which may also allow standard deviation which may be used for something like a kalman filter or complementary filter to estimate the predicted next sample

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

15 Jul 2018 15:45 #114222

by OT-CNC

Replied by OT-CNC on topic Rods "Spaceship" Scratch built Plasma Cutter build

Ditch that rigid coupling. Not sure what brand you used on the helical coupling but a good name brand one should work. Another option is bellows style servo coupling but you need minimal parallel misalignment.

ruland bellow couplings

ruland bellow couplings

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

15 Jul 2018 16:02 #114223

by robertspark

Replied by robertspark on topic Rods "Spaceship" Scratch built Plasma Cutter build

What misalignment do you have

Are the parallel, but misaligned

Or are they not parallel.

Is it not possible to shim the motor or motor mount (tin foil, as used in the kitchen sometimes works if you have no shim steel), I've seen wax paper used too

Are the parallel, but misaligned

Or are they not parallel.

Is it not possible to shim the motor or motor mount (tin foil, as used in the kitchen sometimes works if you have no shim steel), I've seen wax paper used too

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

15 Jul 2018 21:43 - 15 Jul 2018 21:46 #114244

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Thanks for the ideas. I'm not sure that I do have backlash from the cheap connector. I just know it could be an issue so I want to eliminate the possibility. I thought with the acceleration and velocities we are using it could be an issue. It looks like the good ones are expensive...

I did order a cheap oldham coupling last night from ebay and will talk to a Aussie high end company later today.

I've been using Google Drive to do the analysis and created a pivot table to analyise the data for each cut height per cut height. I've attached a Open Office copy but I don't think the pivot table is live so I'd redo it. You'll see it includes all of the standard deviations etc.for each cut height.

I also did some probing of the cut before the surface before the cut but I could not work out a simple way to incorporate that into the results

Believe it or not, this was collected in one 6" long cut using halsampler and the probe features. The time was in the analysis and data cleanup. Originally, I had 19,000 readings but discarded the leadin and the sections where it was changing height. Just be aware the data for each height is in two places as I went up the staircase and back down again.

I did try my best beercan shimming. Usually I mount steppers on 4 threaded posts so I can align it by screwing the posts up and down to get perfect alignment but in this case I bought a ready made bracket so its not able to align it easily and I think its out in 2 planes.

I did order a cheap oldham coupling last night from ebay and will talk to a Aussie high end company later today.

I'd be interested in buying some of your data (it's obviously cost you a bit in materials and damaged parts to get)

I'd like to look at calculating not only the volts per mm but also the variance in the data and standard deviation which may also allow standard deviation which may be used for something like a kalman filter or complementary filter to estimate the predicted next sample

I've been using Google Drive to do the analysis and created a pivot table to analyise the data for each cut height per cut height. I've attached a Open Office copy but I don't think the pivot table is live so I'd redo it. You'll see it includes all of the standard deviations etc.for each cut height.

I also did some probing of the cut before the surface before the cut but I could not work out a simple way to incorporate that into the results

Believe it or not, this was collected in one 6" long cut using halsampler and the probe features. The time was in the analysis and data cleanup. Originally, I had 19,000 readings but discarded the leadin and the sections where it was changing height. Just be aware the data for each height is in two places as I went up the staircase and back down again.

What misalignment do you have

Are the parallel, but misaligned

Or are they not parallel.

Is it not possible to shim the motor or motor mount (tin foil, as used in the kitchen sometimes works if you have no shim steel), I've seen wax paper used too

I did try my best beercan shimming. Usually I mount steppers on 4 threaded posts so I can align it by screwing the posts up and down to get perfect alignment but in this case I bought a ready made bracket so its not able to align it easily and I think its out in 2 planes.

Last edit: 15 Jul 2018 21:46 by rodw.

The following user(s) said Thank You: robertspark

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

15 Jul 2018 23:27 #114250

by robertspark

Replied by robertspark on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod,

Thanks for the data (tomorrows task).

If its out in two planes that can be a PIA IMHO, because the couplings are normally designed to accomodate 1 plane....

The oldham couplings are (IMHO) for parrallel shafts which are misaligned.

Also worth considering is that the acceleration we use with THC puts a LOT of load on anything (in my case 0.3g), hence I'd make sure I had flats not just on the stepper motor, but also the z-axis to assist in taking up the load.

Also of note is the coupling design, the "spring" shaped ones (continuous cut spiral) of aluminium which seem to allow for 2 plane misalignment better (IMHO) than the oldham (SOLID) couplings will are likley to "compress" (wind inward) and unwind when the acceleration is high (and the force imposed is high).

The plastic / rubber lined "plum" couplings are also a bit of an odd one in my opinion as again they work well in two plane misalignment , but again the rubber will compress at acceleration (and deceleration).

This is where S-curve acceleration comes in for assistance.....

Its not the acceleration but the jolt (sometimes called jerk too) when the acceleration goes from one stable velocity (be it zero or some other number) and a change of acceleration (or deceleration) is added to change the velocity. In trapezoidal acceleration this change in acceleration happens "near" instantly....... within 1 microstep actually.

Thanks for the data (tomorrows task).

If its out in two planes that can be a PIA IMHO, because the couplings are normally designed to accomodate 1 plane....

The oldham couplings are (IMHO) for parrallel shafts which are misaligned.

Also worth considering is that the acceleration we use with THC puts a LOT of load on anything (in my case 0.3g), hence I'd make sure I had flats not just on the stepper motor, but also the z-axis to assist in taking up the load.

Also of note is the coupling design, the "spring" shaped ones (continuous cut spiral) of aluminium which seem to allow for 2 plane misalignment better (IMHO) than the oldham (SOLID) couplings will are likley to "compress" (wind inward) and unwind when the acceleration is high (and the force imposed is high).

The plastic / rubber lined "plum" couplings are also a bit of an odd one in my opinion as again they work well in two plane misalignment , but again the rubber will compress at acceleration (and deceleration).

This is where S-curve acceleration comes in for assistance.....

Its not the acceleration but the jolt (sometimes called jerk too) when the acceleration goes from one stable velocity (be it zero or some other number) and a change of acceleration (or deceleration) is added to change the velocity. In trapezoidal acceleration this change in acceleration happens "near" instantly....... within 1 microstep actually.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

16 Jul 2018 02:58 #114266

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I had a play with this calculator www.servotak.eu/tools/engineering_calculator and it seems the acceleration forces for a mass weighing 2-3 kg is from between 2.2-3.3 Newtons using my velocity and acceleration settings. Thats kinda the weight range of my torch and the stage it sits on.

When I looked at the high quality Helix and multibeam couplings, the maximum torque was 1.2 N. So clearly my cheap eBay one was way out of its depth.

So that leaves me with the Oldham coupling which is good for 1 deg misalignment. I think that is probably enough. I can get them unbored in Australia so I'd just need to bore them to my shaft sizes. 25mm dia can handle 3.3 Nm and 33mm dia can handle about 4Nm. I'd probably go with tthe 33mm ones. The data says that the deflection is only an issue with long runs in one direction (eg 24 hours. The 33mm one is good for 4 hours on load time per 24 hours and 0.35 deg deflection. OUr onload time is much shorter durations than that as its really only on acceleration. And even then .35 deg on a 5mm ball screw is only 0.005mm which is better than spec for a plasma machine. Equates to 0.03 of a volt which is way less than the arc hysteresis in my data.

I have a Plum style on order via eBay but I can't find any specs of this style.

When I looked at the high quality Helix and multibeam couplings, the maximum torque was 1.2 N. So clearly my cheap eBay one was way out of its depth.

So that leaves me with the Oldham coupling which is good for 1 deg misalignment. I think that is probably enough. I can get them unbored in Australia so I'd just need to bore them to my shaft sizes. 25mm dia can handle 3.3 Nm and 33mm dia can handle about 4Nm. I'd probably go with tthe 33mm ones. The data says that the deflection is only an issue with long runs in one direction (eg 24 hours. The 33mm one is good for 4 hours on load time per 24 hours and 0.35 deg deflection. OUr onload time is much shorter durations than that as its really only on acceleration. And even then .35 deg on a 5mm ball screw is only 0.005mm which is better than spec for a plasma machine. Equates to 0.03 of a volt which is way less than the arc hysteresis in my data.

I have a Plum style on order via eBay but I can't find any specs of this style.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

16 Jul 2018 04:05 #114274

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

I phoned the bearing shop I have an account with becasue I remembered they had a range of linear motion components.

They do this one www.tbimotion.com.tw/product/category/20/1/en

He's getting a 30mm and a 20mm dia one in from interstate. They are rated for 5N and 12.5N respectively and are still good for 1 degree angular misalignment. He said it was a good idea to use them with a shaft diameter mid-range to the quoted size. Either way, one end will be at the end of the range so I'm favouring the 30mm diameter one for now\ which is only $10 dearer than the 20mm one.

They need to be bored out to suit my shaft sizes.

So I should have this fixed by the end of the week.

They do this one www.tbimotion.com.tw/product/category/20/1/en

He's getting a 30mm and a 20mm dia one in from interstate. They are rated for 5N and 12.5N respectively and are still good for 1 degree angular misalignment. He said it was a good idea to use them with a shaft diameter mid-range to the quoted size. Either way, one end will be at the end of the range so I'm favouring the 30mm diameter one for now\ which is only $10 dearer than the 20mm one.

They need to be bored out to suit my shaft sizes.

So I should have this fixed by the end of the week.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

17 Jul 2018 13:03 #114378

by andypugh

In the configs where you do not use external offsets, how do you offset the Z?

I am completely puzzled by how a HAL-only solution can be better than an integrated solution to moving an axis outside the control of G-code.

Replied by andypugh on topic Rods "Spaceship" Scratch built Plasma Cutter build

I said on another thread I'd give the external offsets thread one more go and yesterday I did about 70 cuts and still did not get a result..

In the configs where you do not use external offsets, how do you offset the Z?

I am completely puzzled by how a HAL-only solution can be better than an integrated solution to moving an axis outside the control of G-code.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11648

- Thank you received: 3919

17 Jul 2018 13:19 #114384

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Andy, I've not given up on the external offsets yet and thats all I've played with in this long winded build. Islander261 has delved deeper into alternatives. grivaljp has a solution that is rolled into a single THC component and his config does not have a Z axis at all. (which scared me a bit).

I am really hoping backlash on acceleration in my efforts to date has been causing eoffset-pid to to overshoot. Its been noted that the pid component in eoffset-pid.comp is not as sophisticated as the linuxcnc pid component so if I don't get a result I was going to try a modified eoffset_pid component that used an external pid.

I am really hoping backlash on acceleration in my efforts to date has been causing eoffset-pid to to overshoot. Its been noted that the pid component in eoffset-pid.comp is not as sophisticated as the linuxcnc pid component so if I don't get a result I was going to try a modified eoffset_pid component that used an external pid.

Please Log in or Create an account to join the conversation.

Time to create page: 0.244 seconds