Rods "Spaceship" Scratch built Plasma Cutter build

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

24 Jan 2019 23:24 #124777

by rodw

Andy, thanks for that. Yes I spent many hours of testing both in Dewey's sim and on the table itself. I even plotted voltage and height with a 16000 point data set to get the sim scaling correct. From memory, I think Dewey said in the docs I gain was not likely to be useful as it was running inside an outer control loop or something. I did try it and it went crazy with small amounts added. In the Sim, it seemed to move the voltage plot up or down from the set point. Maybe the Inner/Outer loop stuff might be behind PCW's theory.

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

The reason I want to slow down the THC thread is that Jim Colt from Hypertherm has said trying to control the Z too tightly or adjusting too quickly results in oscillations. Also, a paper I found on Industrial PID control said that motors should not be controlled too tightly

You wouldn't normally do that by slowing the thread, you do that by turning the gains down.

Have you tried lower gains? I think I would expect it all to be handled mainly by I gain.

Andy, thanks for that. Yes I spent many hours of testing both in Dewey's sim and on the table itself. I even plotted voltage and height with a 16000 point data set to get the sim scaling correct. From memory, I think Dewey said in the docs I gain was not likely to be useful as it was running inside an outer control loop or something. I did try it and it went crazy with small amounts added. In the Sim, it seemed to move the voltage plot up or down from the set point. Maybe the Inner/Outer loop stuff might be behind PCW's theory.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

25 Jan 2019 03:55 - 25 Jan 2019 03:57 #124789

by islander261

Replied by islander261 on topic Rods "Spaceship" Scratch built Plasma Cutter build

Rod

I had a look at an old .ini file of yours from last spring. In that file you have a Z axis step scale of 1000 (1000steps/mm?), if so that is about 4 to 10 times more resolution than you need. As I recall you have a belt driven reduction driving a ball screw on your Z axis. Reduce the micro stepping on your drive by a factor between 4 and 10 and you should see a torque increase. I don't know if your drives do step morphing but my Geckos change from 10 to full step at about 1/2rps motor speed to get morel torque when moving fast. The max speed on my Z is 220ipm or about 5.588mpm and when cutting it is limited to between 1/2 and 1/3 of that for stability, I don't cut corrugated sheet.

John

I had a look at an old .ini file of yours from last spring. In that file you have a Z axis step scale of 1000 (1000steps/mm?), if so that is about 4 to 10 times more resolution than you need. As I recall you have a belt driven reduction driving a ball screw on your Z axis. Reduce the micro stepping on your drive by a factor between 4 and 10 and you should see a torque increase. I don't know if your drives do step morphing but my Geckos change from 10 to full step at about 1/2rps motor speed to get morel torque when moving fast. The max speed on my Z is 220ipm or about 5.588mpm and when cutting it is limited to between 1/2 and 1/3 of that for stability, I don't cut corrugated sheet.

John

Last edit: 25 Jan 2019 03:57 by islander261. Reason: changed torque at high speed

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

25 Jan 2019 04:34 #124791

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

John, thanks, I might give that a try. Currently I think I'm using 25x microstepping. I thought the drives have step morphing on them.

I got the machine wired up this morning. The arcOK and torch work but something funky is happening with the torch voltage showing negative volts so I must have a connection wrong somewhere..

However, I am cutting again!

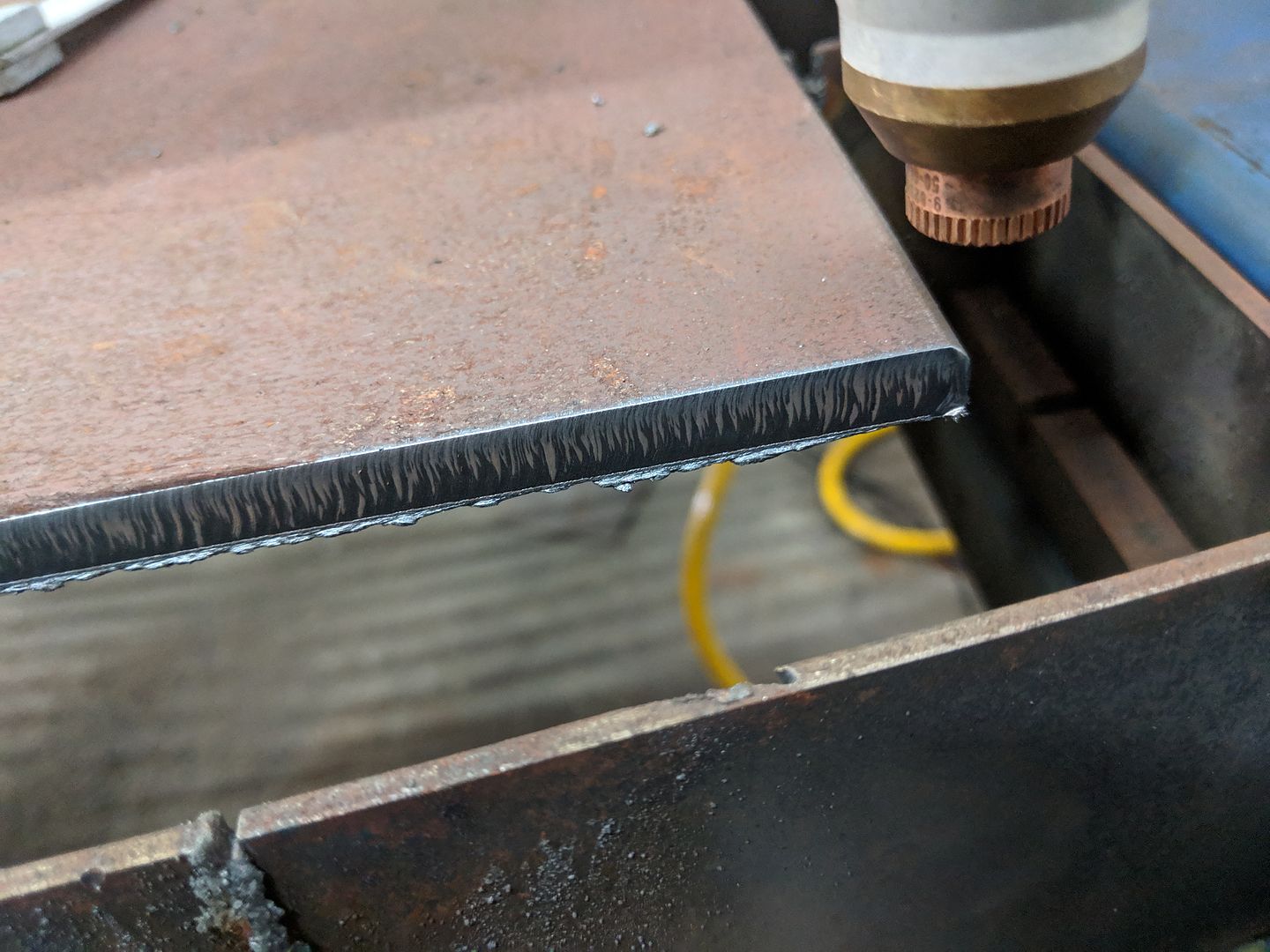

This is 8mm steel at 80 amps at book speed. I met my neighbour at the back door right behind the plasma cutter with the offcut who gave me a post mortem and said to increase the cutting speed to fix the low speed dross on the lower side. Nice to have an expert tutor so handy! Anyway, the cut is square. I did find the higher stand off while cutting (4.8mm) needed more attention to eye protection as the arc is very bright!

I got the machine wired up this morning. The arcOK and torch work but something funky is happening with the torch voltage showing negative volts so I must have a connection wrong somewhere..

However, I am cutting again!

This is 8mm steel at 80 amps at book speed. I met my neighbour at the back door right behind the plasma cutter with the offcut who gave me a post mortem and said to increase the cutting speed to fix the low speed dross on the lower side. Nice to have an expert tutor so handy! Anyway, the cut is square. I did find the higher stand off while cutting (4.8mm) needed more attention to eye protection as the arc is very bright!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

25 Jan 2019 10:40 #124800

by andypugh

Microstepping doesn't decrease motor torque.

Replied by andypugh on topic Rods "Spaceship" Scratch built Plasma Cutter build

Reduce the micro stepping on your drive by a factor between 4 and 10 and you should see a torque increase

Microstepping doesn't decrease motor torque.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

25 Jan 2019 11:03 #124801

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

Well, I did a bit more digging with a multimeter while cutting and found the divided voltage at the THCAD input was measuring in the millivolt range when it should have been around 4.3 volts according to the book specs. I had a good chat with the supplier who was very helpful. The most logical reason was that the standard CNC board on this machine without a divided volts output was fitted. But I opened the inverter again and confirmed the board fitted was the Automation Interface with Divided voltage output by the part number. I found my busted THCAD board and removed the input socket from it so I will wire it into a multimeter and check the voltages without it connected to the THCAD as I've been caught with divider boards before! I'm sure I'll sort it out pretty quick.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

25 Jan 2019 11:45 #124805

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

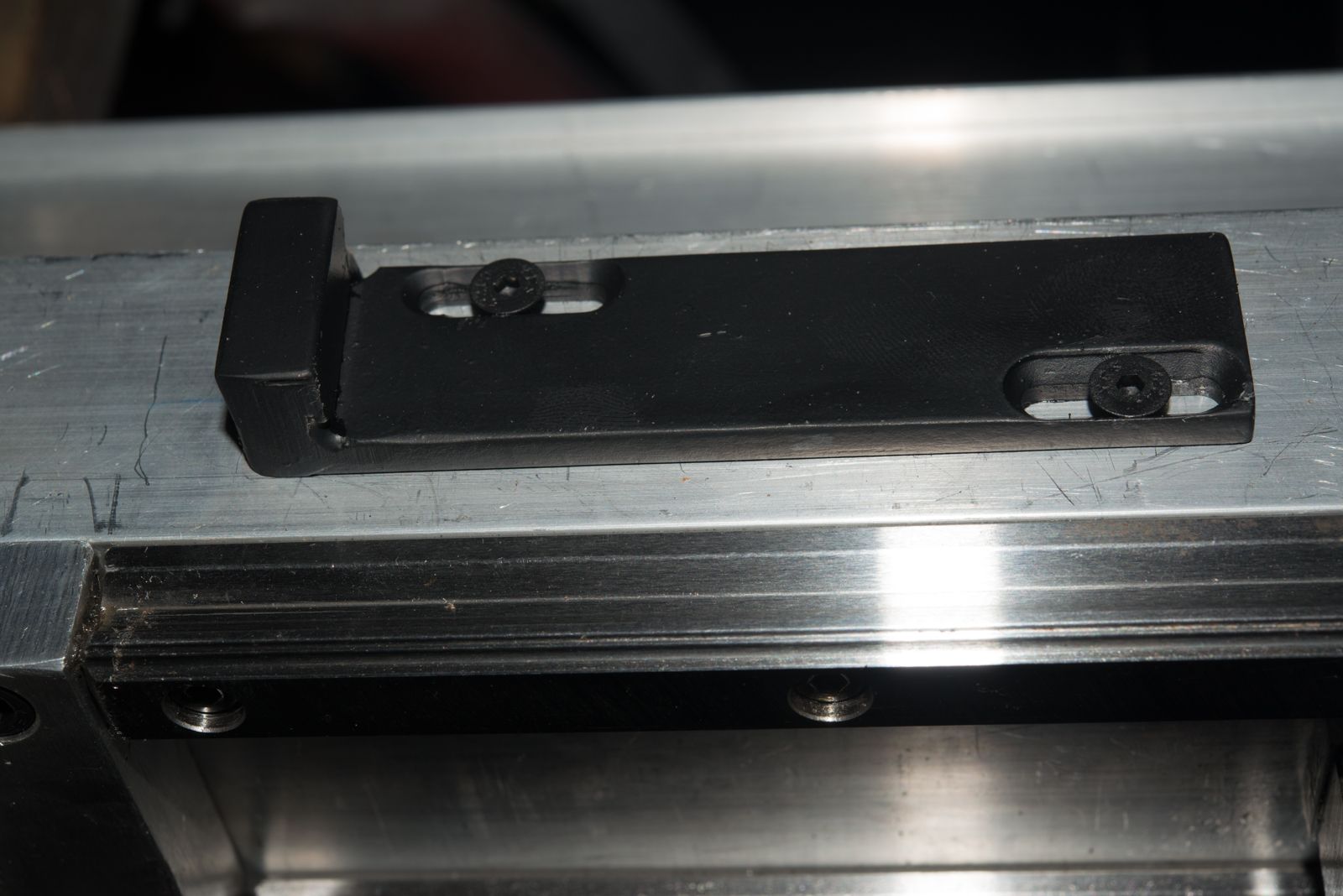

Just on a side note, while I was browsing through the forum, I had a BFO (blinding flash of the obvious) about how I do homing with my prox switches. I use these sensor plates at each end of the X and Y axes

When I started out, I don't think many people were using master branch but I started to use it to get the joint axis gantry homing. I think it was some of the recent comments by Andy that made the penny drop.

Every now and again, I have noticed the X axis get confused when homing and now I realised that if the home switch sensor was over the flat plate at the max limit axis end, it thought it was close to the home switch so it moved the wrong way in an attempt to move away from the home switch.... So my machine design is wrong. I need to reverse the sensor plates at the max limit end so the max limit can be adjusted but the home sensor is never triggered at this end of the gantry. And here was I thinking how cool my home/limit switch sensor set up was for the last 2 years!

When I started out, I don't think many people were using master branch but I started to use it to get the joint axis gantry homing. I think it was some of the recent comments by Andy that made the penny drop.

Every now and again, I have noticed the X axis get confused when homing and now I realised that if the home switch sensor was over the flat plate at the max limit axis end, it thought it was close to the home switch so it moved the wrong way in an attempt to move away from the home switch.... So my machine design is wrong. I need to reverse the sensor plates at the max limit end so the max limit can be adjusted but the home sensor is never triggered at this end of the gantry. And here was I thinking how cool my home/limit switch sensor set up was for the last 2 years!

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

28 Jan 2019 06:24 #125042

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

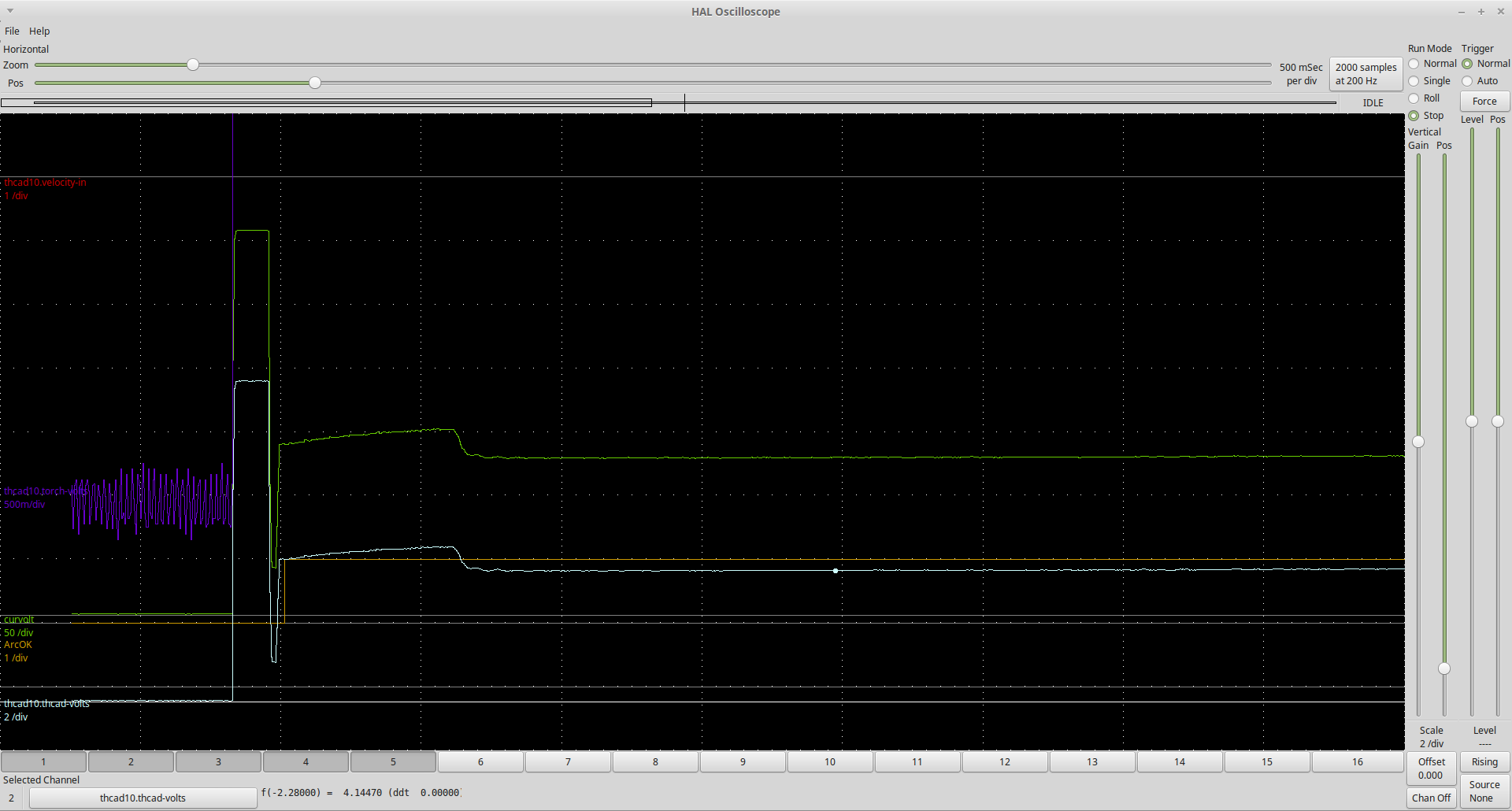

They don't make it easy for you. I had problems earlier in the week getting a voltage into the THAD board. So after a good few hours this morning starting with a 9 volt battery, wiring in a multimeter, reverting to raw arc voltage and adding the appropriate scaling resistors, the problem was the polarity of both the raw arc voltage and divided arc voltage were reversed from both the manual and the diagram on the machine itself. This is the second machine I've had with incorrect documentation.

This looks about right. 126 volts vs book setting of 131 volts for this cut

So now a question for PCW. With the 30:1 divider selected, the THAD is hitting its full scale briefly at the beginning of a cut. You can see that in the halscope plot above. Is this anything to worry about or should I change the divider settings so it stays in range?

This looks about right. 126 volts vs book setting of 131 volts for this cut

So now a question for PCW. With the 30:1 divider selected, the THAD is hitting its full scale briefly at the beginning of a cut. You can see that in the halscope plot above. Is this anything to worry about or should I change the divider settings so it stays in range?

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17640

- Thank you received: 5161

28 Jan 2019 13:18 #125071

by PCW

Replied by PCW on topic Rods "Spaceship" Scratch built Plasma Cutter build

You can overrange the the THCAD10 input 50X (500V) continuously so there's nothing to worry about. As a matter of fact, overranging the input is a valid way to get a bit better resolution if you dont expect to run the height control at say >200V

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

28 Jan 2019 20:10 #125091

by Grotius

Replied by Grotius on topic Rods "Spaceship" Scratch built Plasma Cutter build

Hi Rod,

Nice to see you cutting again. Keep up the good work !!

Nice to see you cutting again. Keep up the good work !!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11690

- Thank you received: 3938

29 Jan 2019 03:53 #125127

by rodw

Replied by rodw on topic Rods "Spaceship" Scratch built Plasma Cutter build

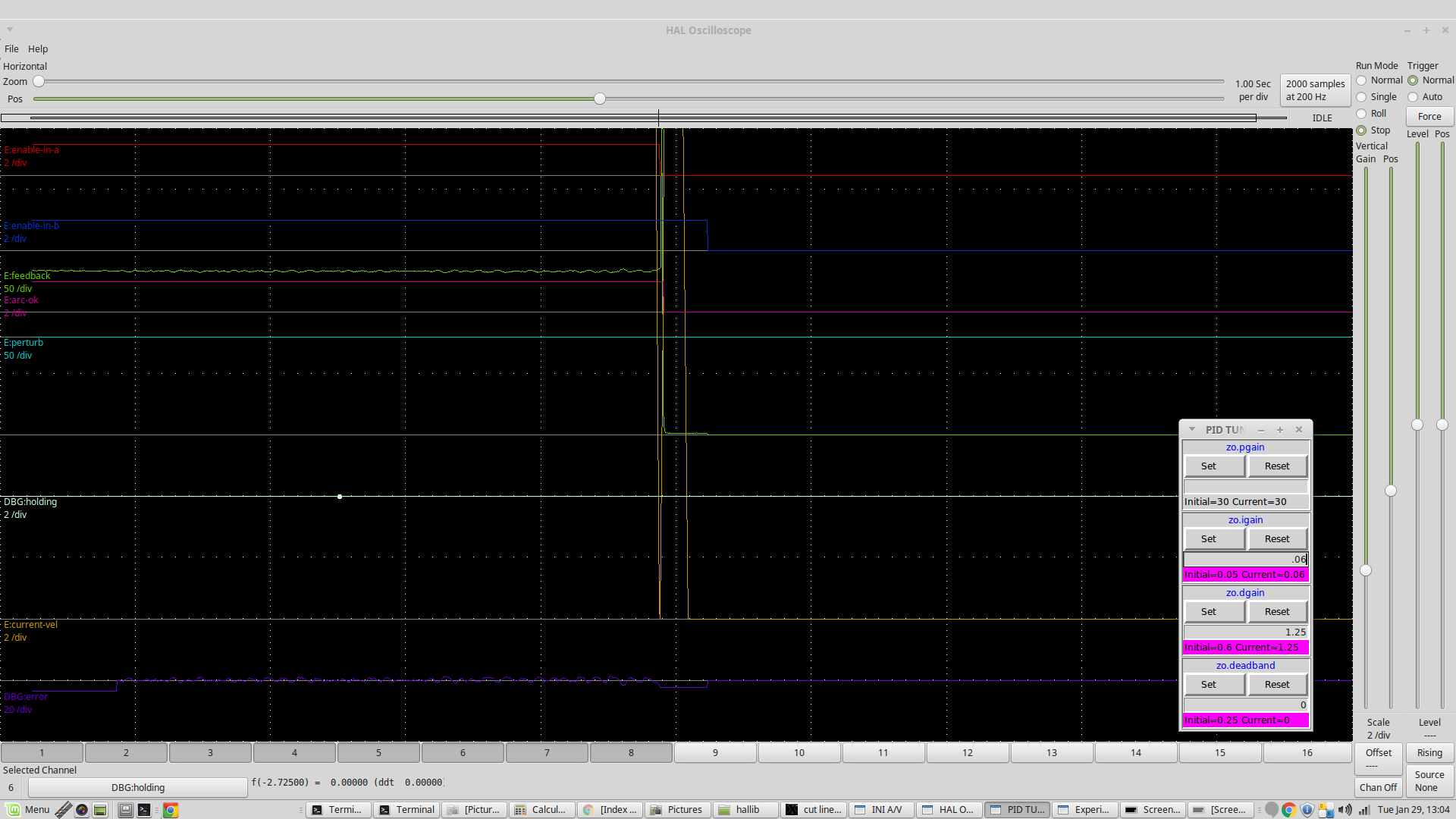

Well, I had a bit of a play today with the external offsets branch.

This was as good as it got.

I took a video of it cutting with these settings, I played around with velocity and acceleration settings as well. I'll podt the video from my phone shortly and you guys can tell me if the Z axis is too busy....

This was as good as it got.

I took a video of it cutting with these settings, I played around with velocity and acceleration settings as well. I'll podt the video from my phone shortly and you guys can tell me if the Z axis is too busy....

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.166 seconds